Silicon germanium film parallel transfer method applied to uncooled infrared focal plane

An uncooled infrared, transfer method technology, applied in the field of parallel transfer of silicon germanium thin films, can solve the problems of uneven ion energy and bonding surface morphology, different bonding strengths of bonding areas, and difficulty in adapting to array manufacturing, etc. The effect of expanding the range of sensitive materials, flexible and controllable thickness, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

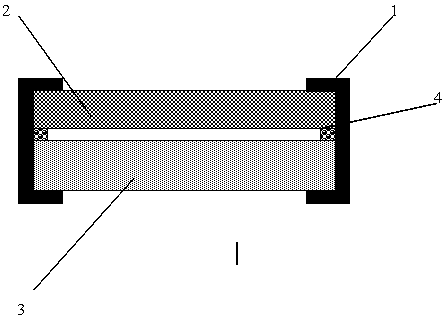

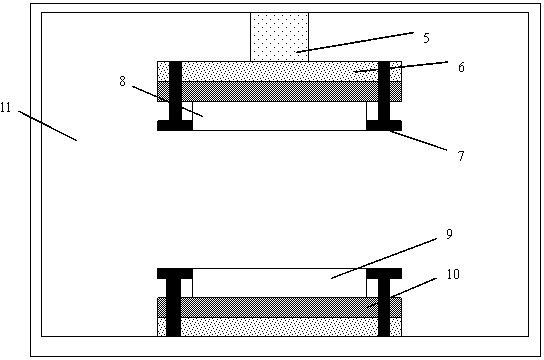

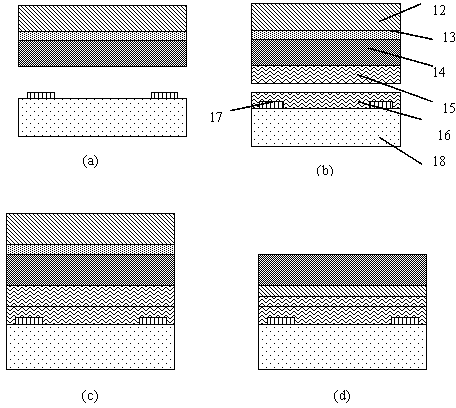

[0026] combine figure 1 , figure 2 with image 3 , the present invention is applied to the silicon germanium thin film parallel transfer bonding technology for the manufacture of uncooled infrared focal planes. Taking mr-i9100m glue and ULTRA-i300 glue as examples, the parallel transfer process is briefly described.

[0027] The process steps of using mr-i9100m glue are as follows:

[0028] Step 1: If image 3 As shown in the cleaning procedure in , follow the RCA1 procedure (mix 25% NH3 solution and deionized water in a ratio of 1 to 5, after boiling, add H2O2 in a ratio of 1 to 6, and then immerse the wafer in the solution for 10 minutes ) cleaning the SOI wafer 2 and the CMOS wafer 3, blowing them dry with nitrogen, and then placing them in an oven at 200° C. for 30 minutes; wherein the SOI wafer 2 sequentially includes a silicon support layer 12, a BOX layer 13, a silicon The germanium thin film 14 , the CMOS wafer includes metal electrodes 17 and CMOS circuits 18 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com