Running detecting device of ring cold machine wheel

A technology of running detection and ring cooler, applied in wheel testing, electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the problems of quickly finding faulty wheels, difficult to find wheels, and lack of post personnel, so as to reduce maintenance work. The effect of reducing the amount and labor intensity, reducing the failure rate of equipment downtime, preventing missed detection and false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

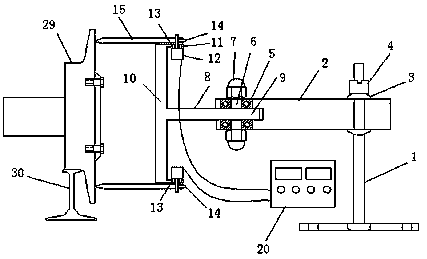

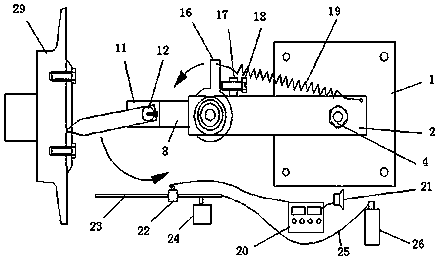

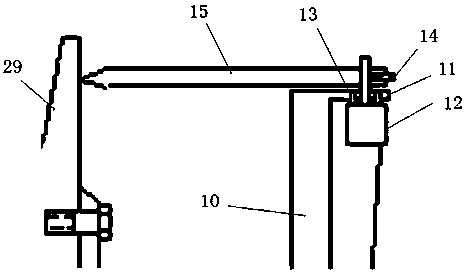

[0019] The invention includes a detecting mechanical arm assembly, a sensing electric control assembly, an alarm assembly and a number spraying pneumatic assembly. The detection probe is installed at the front end of the detection manipulator assembly, and the detection probe directly touches the upper and lower hubs on the end face of the wheel. The detection probe is connected to the potentiometer, and the potentiometer sends a resistance signal to the sensor circuit The control component is processed, and the alarm component and the spray number pneumatic component are driven.

[0020] figure 1 , 2 It is shown that the main components of the detection manipulator assembly include a mounting bracket 1 , an extension arm 2 , a rotating arm 8 , a potentiometer 12 , and a detection probe 15 . The installation bracket 1 is placed vertically on the ground, one end of the extension arm 2 is fixedly connected with the upper end of the installation bracket 1, the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com