Evaluation method for failure of contact hole

A technology of failure evaluation and contact hole, which is applied in the direction of color/spectral characteristic measurement, semiconductor/solid-state device testing/measurement, etc. It can solve problems such as missed detection of failed contact holes, difficulty in distinguishing detection machines, and large color difference values. To achieve the effect of avoiding missed or wrong detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

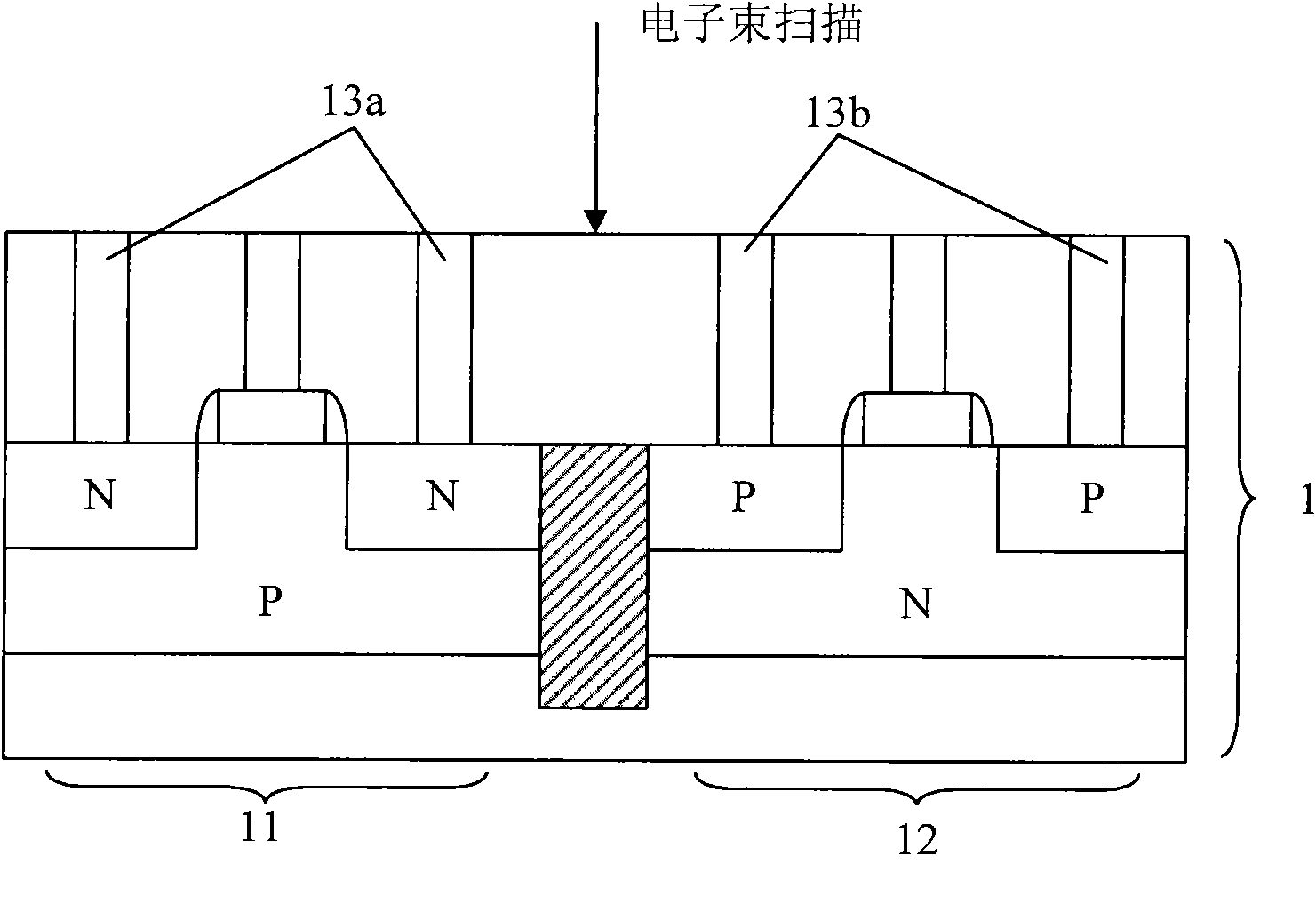

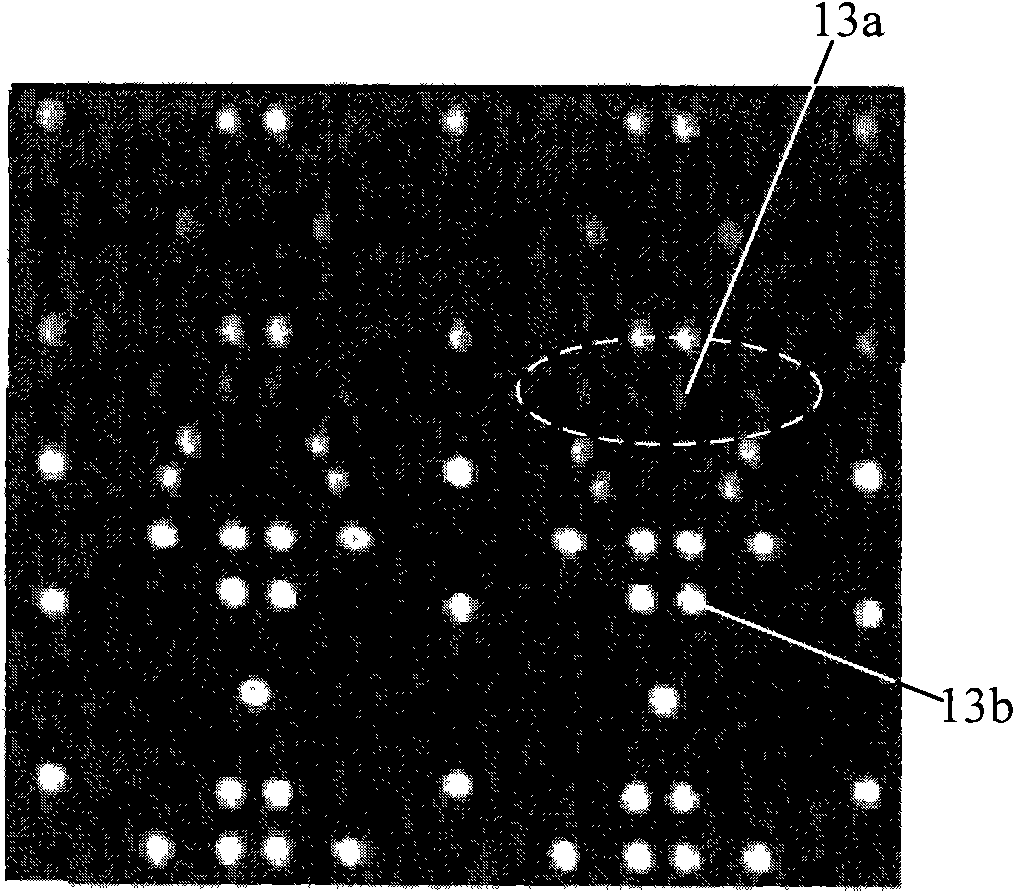

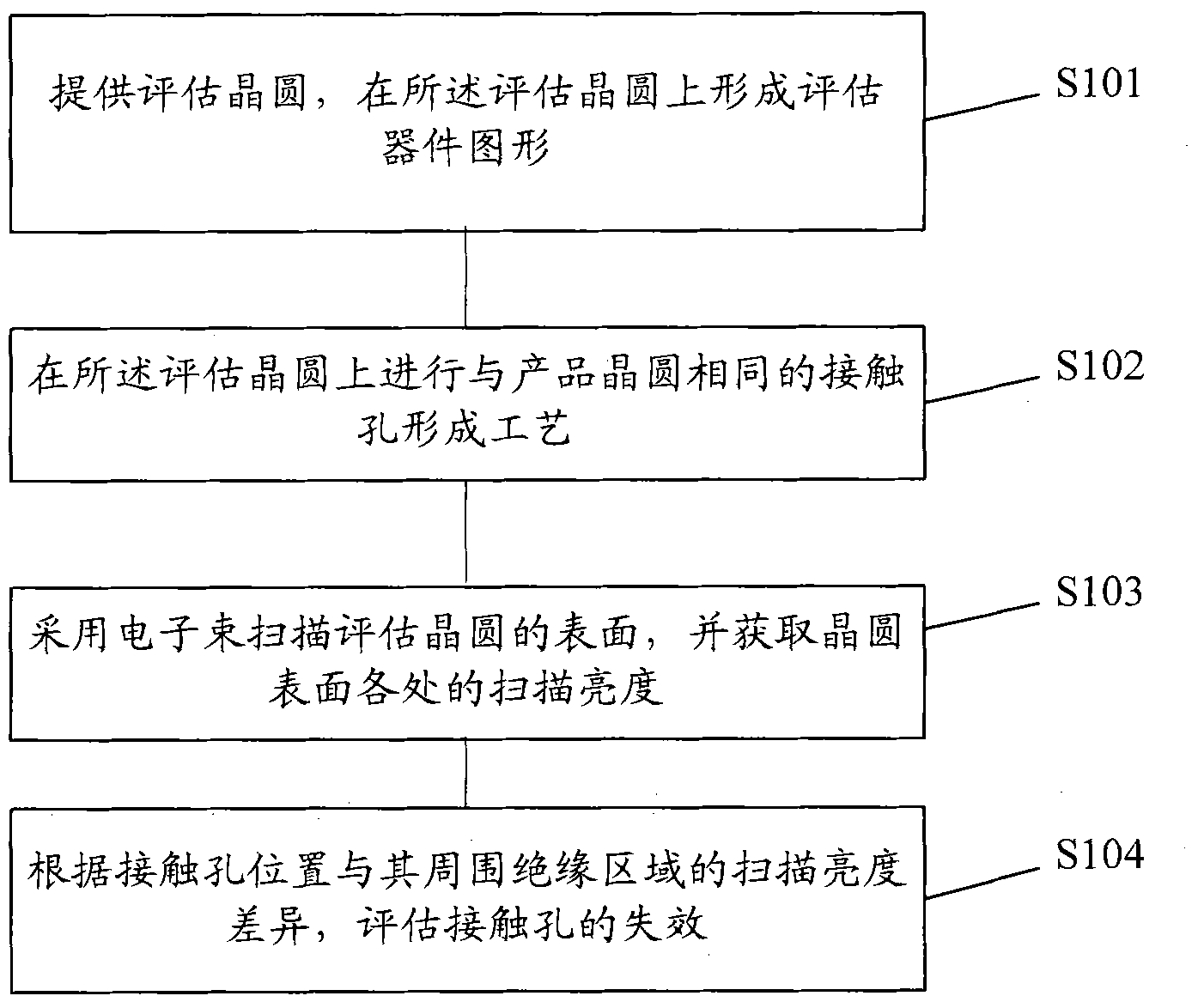

[0030] In the existing contact hole failure evaluation method, the contact hole located on the N-type doped active region shows a gray spot on the color difference diagram when the electron beam is scanned, which is difficult to distinguish from the black of the surrounding insulating region, resulting in mechanical failure. Missed or wrong detection of failed contact holes by the platform. The present invention provides an evaluation wafer having a device pattern similar to the product wafer, so that the N-type or P-type doped active regions on the evaluation wafer have a strong ability to conduct electricity and release charges, so that the electron beam scans at When the contact holes in the above-mentioned active regions are present, they appear as white spots on the color difference diagram, which are easy to distinguish, thereby avoiding the above-mentioned situation of missed detection or wrong detection.

[0031] The present invention will be described in detail below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com