Experimental test device and method for forced imbibition capability of shale

A testing device and imbibition technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not comprehensively considering the impact of shale, and achieve a good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific embodiment of the present invention will be described in detail below according to the accompanying drawings and a shale well in Sichuan area as an example. details as follows:

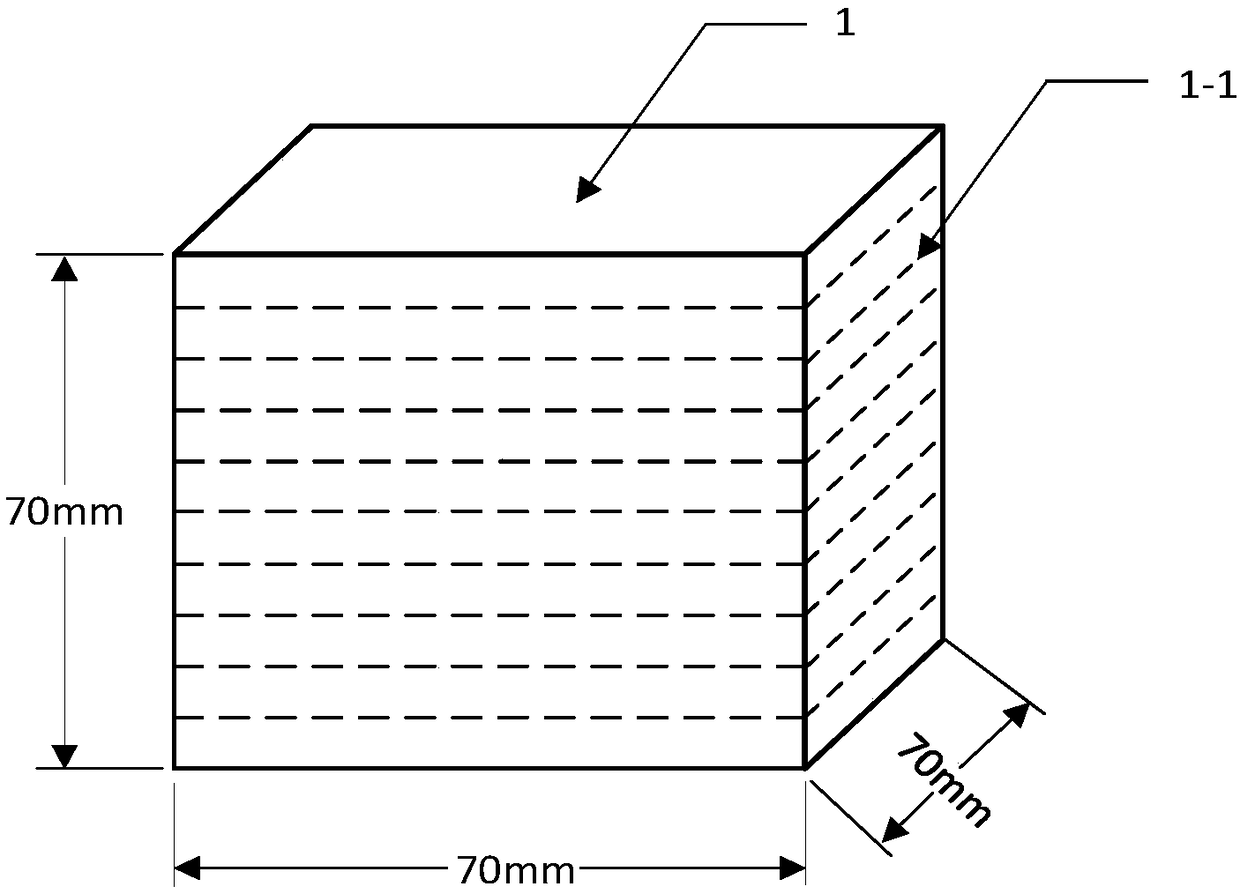

[0039] ①. Rock sample preparation: Take the actual downhole core of the 2415-2460m reservoir section of Well Y1, and make two cube rock samples with a side length of 7cm±1mm, namely rock sample A and rock sample B, and place the rock samples Dry in an oven at 100°C to constant weight, and calculate the imbibition area A of the two rock samples based on the size of the core c and length L are 49cm 2 and 7cm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com