Driving device structure of supersonic seal device

A sealing device and driving device technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of piezoelectric ceramic sheets, and achieve the effect of reducing bending stress and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

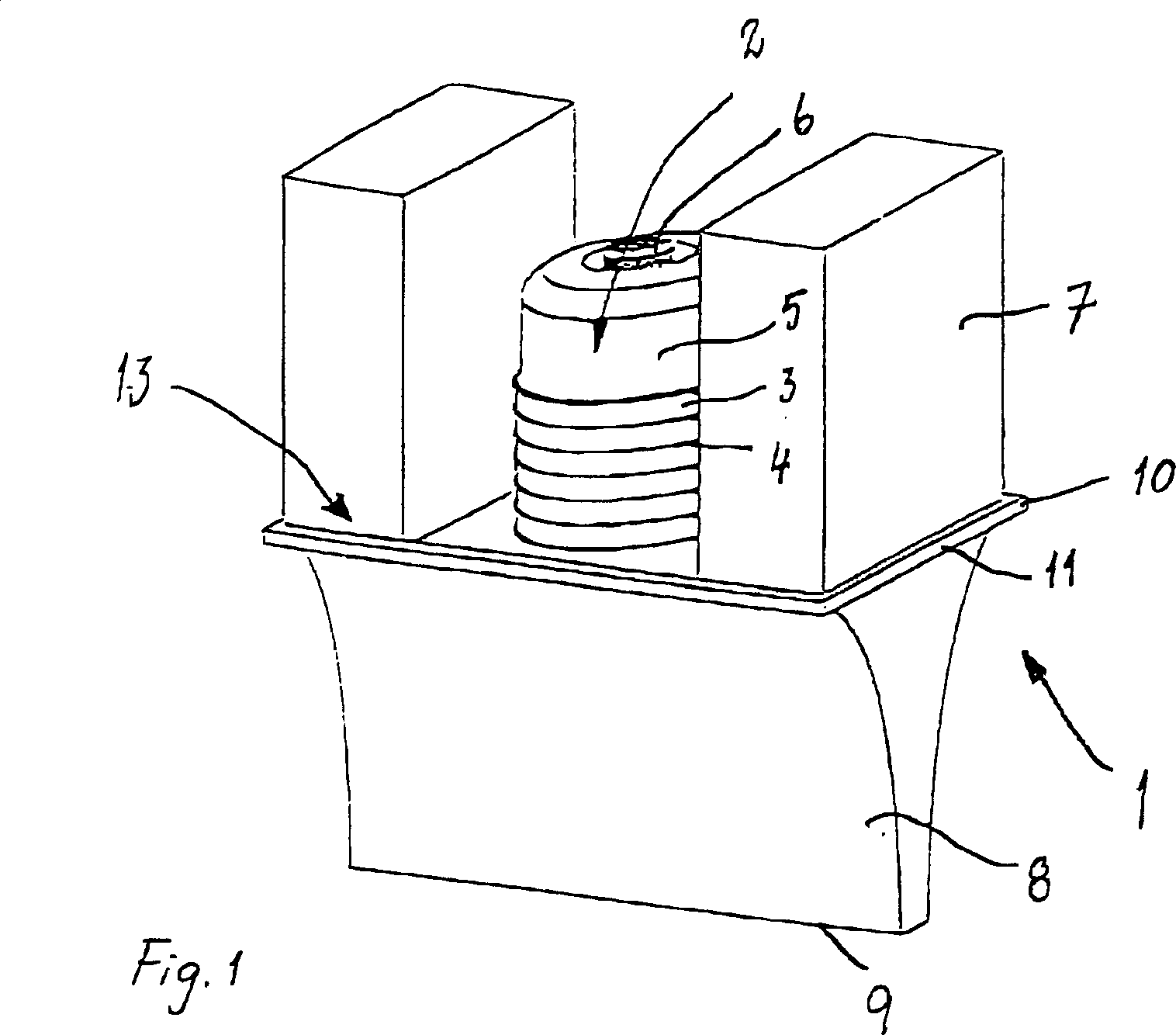

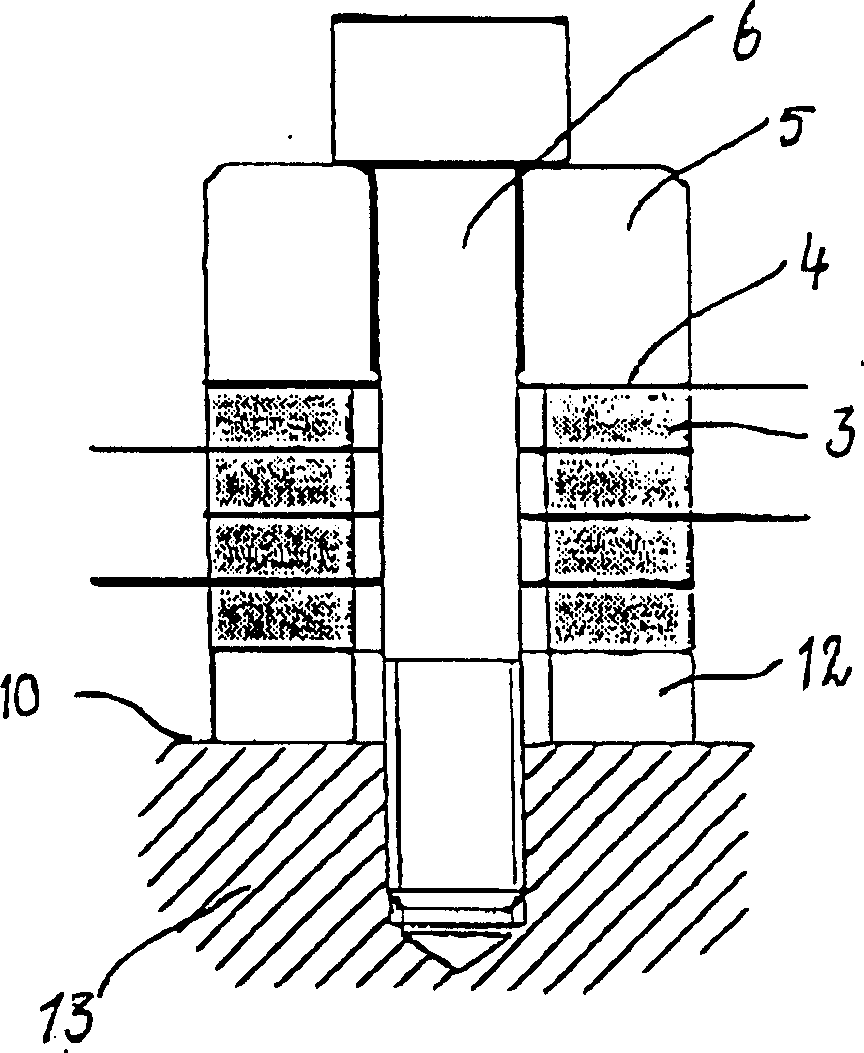

[0014] The structure according to the invention for the ultrasonic seal 1 shown in FIG. 1 or a similar seal 1 has been specially developed and produced 3 . The sealing device 1 essentially consists of a drive device 2 and a homogeneous body 13 .

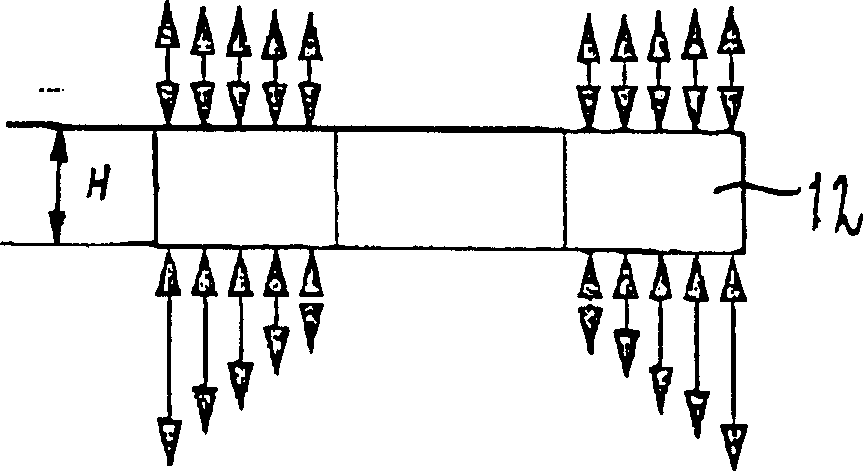

[0015] The driving device 2 of the sealing device 1 includes several piezoelectric ceramic sheets 3, and several conductive metal sheets 4 are arranged in the middle of the ceramic sheets. These metal pieces 4 are connected to an AC power source (not shown) in order to electrically connect the above-mentioned piezoelectric ceramic pieces 3 in parallel. The ceramic sheet 3 and the metal sheet 4 are fixed together with a balance weight 5 through the compression screw 6 in a pre-tightened manner. The compression screw 6 is also used to secure the drive device 2 in the homogeneous body 13 of the sealing device 1 . The drive unit 2 converts the voltage into a mechanical displacement which causes vibrations constituting the sealing actio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com