Nano antibacterial plastic and preparation method thereof

An antibacterial plastic and nanotechnology, applied in the polymer field, can solve the problems of bacterial drug resistance, poor mechanical properties, easy discoloration, etc., and achieve the effects of excellent antibacterial properties, good mechanical properties, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

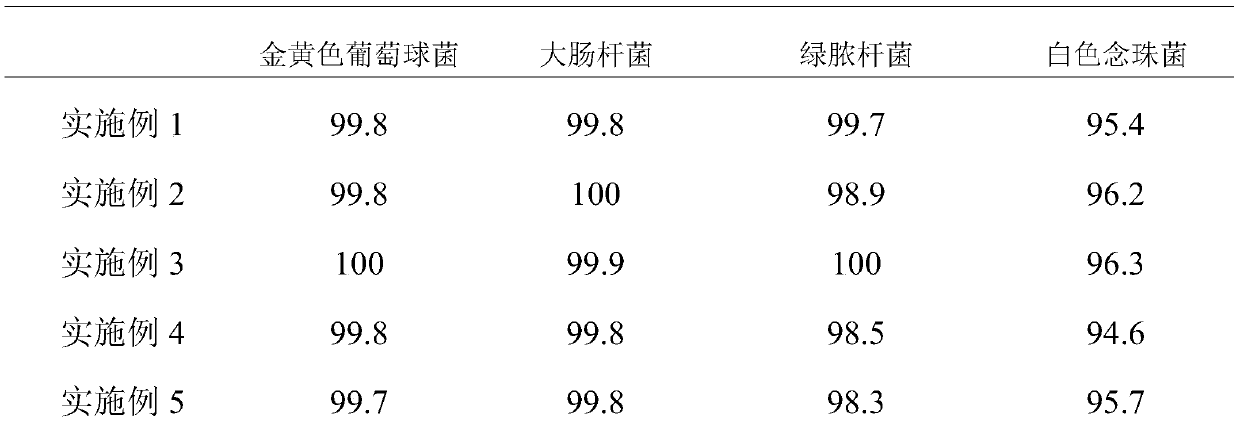

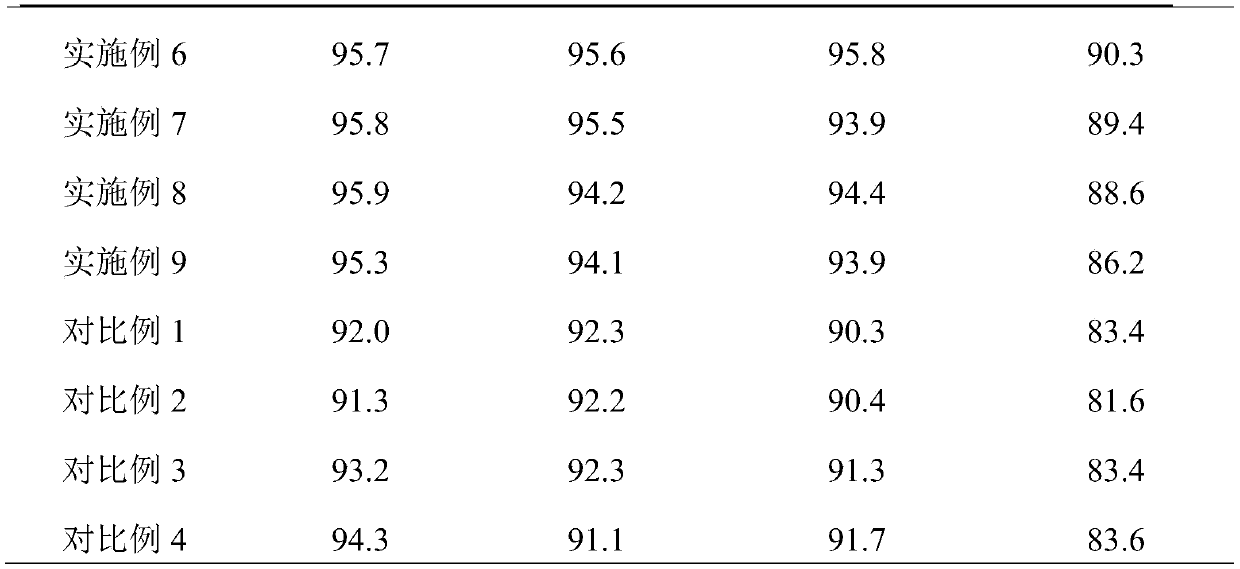

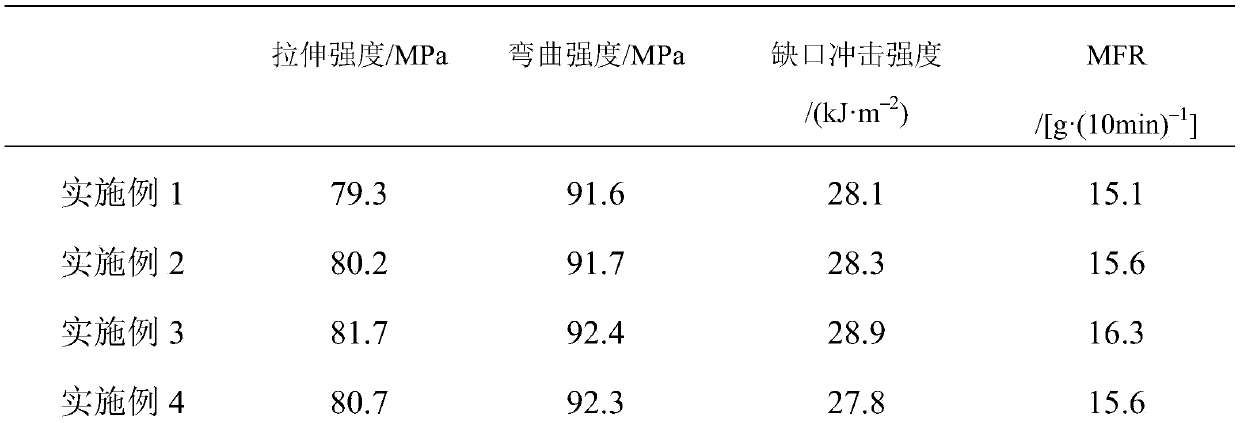

Examples

Embodiment 1

[0024] A nano antibacterial plastic: comprising the following raw materials in parts by weight: 150-180 parts of low-density polyethylene, 40-80 parts of dioctyl phthalate, 20-40 parts of nano-zinc oxide powder, 15-36 parts of silver ammonia solution, 21-25 parts of nano titanium dioxide, 10-15 parts of zinc stearate, 2-8 parts of oleic acid amide, 1-4 parts of antioxidant, 8-10 parts of eucalyptus oil, 3-5 parts of Sansevieria oil.

Embodiment 2

[0026] A nano antibacterial plastic: comprising the following raw materials in parts by weight: 150-180 parts of low-density polyethylene, 40-80 parts of dioctyl phthalate, 20-40 parts of nano-zinc oxide powder, 15-36 parts of silver ammonia solution, 21-25 parts of nano titanium dioxide, 10-15 parts of zinc stearate, 2-8 parts of oleic acid amide, 1-4 parts of antioxidant, 8-10 parts of eucalyptus oil, 3-5 parts of Sansevieria oil.

Embodiment 3

[0028] A nano antibacterial plastic: comprising the following raw materials in parts by weight: 160 parts of low-density polyethylene, 60 parts of dioctyl phthalate, 30 parts of nano-zinc oxide powder, 25 parts of silver ammonia solution, 23 parts of nano-titanium dioxide, stearic acid 13 parts of zinc, 5 parts of oleic acid amide, 3 parts of antioxidant, 9 parts of eucalyptus oil, 4 parts of sansevieria oil;

[0029] Use the weight part raw material of embodiment 1~3 to prepare nano antibacterial plastic, comprise the following steps:

[0030] S1. Add the above silver ammonia solution to silver ammonia solution with 15% sodium carboxymethyl cellulose, polyamide and vinyl acetate, carry out microwave oscillation for 2 hours at a power of 230W and an oscillation frequency of 850MHz, adjust the pH of the solution to 7, and add nano Zinc oxide powder and propyl gallate were mechanically stirred for 3 hours at a temperature of 15°C, a frequency of 120MHz, and an electric field str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com