Nut peeling machine

A peeling machine and nut technology, applied in the field of agricultural machinery, can solve the problems of low efficiency, low rate of green peel removal, and low operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

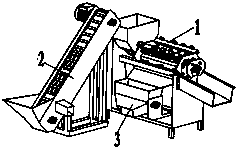

[0025] Embodiment 1: as Figure 1-7 As shown, a nut peeling machine includes peeling device 1, grading feeding device 2 and green skin crushing device 3; wherein grading feeding device 2 is placed on the left side of peeling device 1, and the outlet of grading feeding device 2 Hopper at peeling unit 1 5 above, green skin crushing device 3 is installed below the green skin discharge port 14 of peeling device 1.

Embodiment 2

[0026] Embodiment 2: as Figure 1-7As shown, a nut peeling machine includes peeling device 1, grading feeding device 2 and green skin crushing device 3; wherein grading feeding device 2 is placed on the left side of peeling device 1, and the outlet of grading feeding device 2 Hopper at peeling unit 1 5 above, green skin crushing device 3 is installed below the green skin discharge port 14 of peeling device 1.

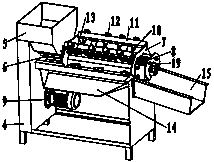

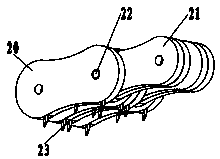

[0027] The peeling device 1 consists of a frame 4. Hopper 5. Screw 6. Knife holder 7. Chain peeling knife 8. Motor 9. Compression spring 10. Spring frame 11. Spring pressure adjustment bolt 12. Compression seat 13. Green skin discharge port 14. Discharge port 15, driving pulley 16, driven pulley I17, flat belt 18 and band diamond seat bearing 19 components; wherein the screw rod 6 passes through the bearing with a rhombic seat 19 rack mounted 4 upper, hopper 5 is installed on the left end of the screw rod 6 and fixed on the frame 4 above. Chain type...

Embodiment 3

[0028] Embodiment 3: as Figure 1-7 As shown, a nut peeling machine includes peeling device 1, grading feeding device 2 and green skin crushing device 3; wherein grading feeding device 2 is placed on the left side of peeling device 1, and the outlet of grading feeding device 2 Hopper at peeling unit 1 5 above, green skin crushing device 3 is installed below the green skin discharge port 14 of peeling device 1.

[0029] The peeling device 1 consists of a frame 4. Hopper 5. Screw 6. Knife holder 7. Chain peeling knife 8. Motor 9. Compression spring 10. Spring frame 11. Spring pressure adjustment bolt 12. Compression seat 13. Green skin discharge port 14. Discharge port 15, driving pulley 16, driven pulley I17, flat belt 18 and band diamond seat bearing 19 components; wherein the screw rod 6 passes through the bearing with a rhombic seat 19 rack mounted 4 upper, hopper 5 is installed on the left end of the screw rod 6 and fixed on the frame 4 above. Chain typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com