Contact for a onion peeling machine

A peeling machine and scallop technology, which is applied in the field of food manufacturing and processing, can solve the problems of reducing work efficiency, small friction coefficient, and prolonging the working time of the peeling machine, so as to achieve the effect of ensuring the peeling effect and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

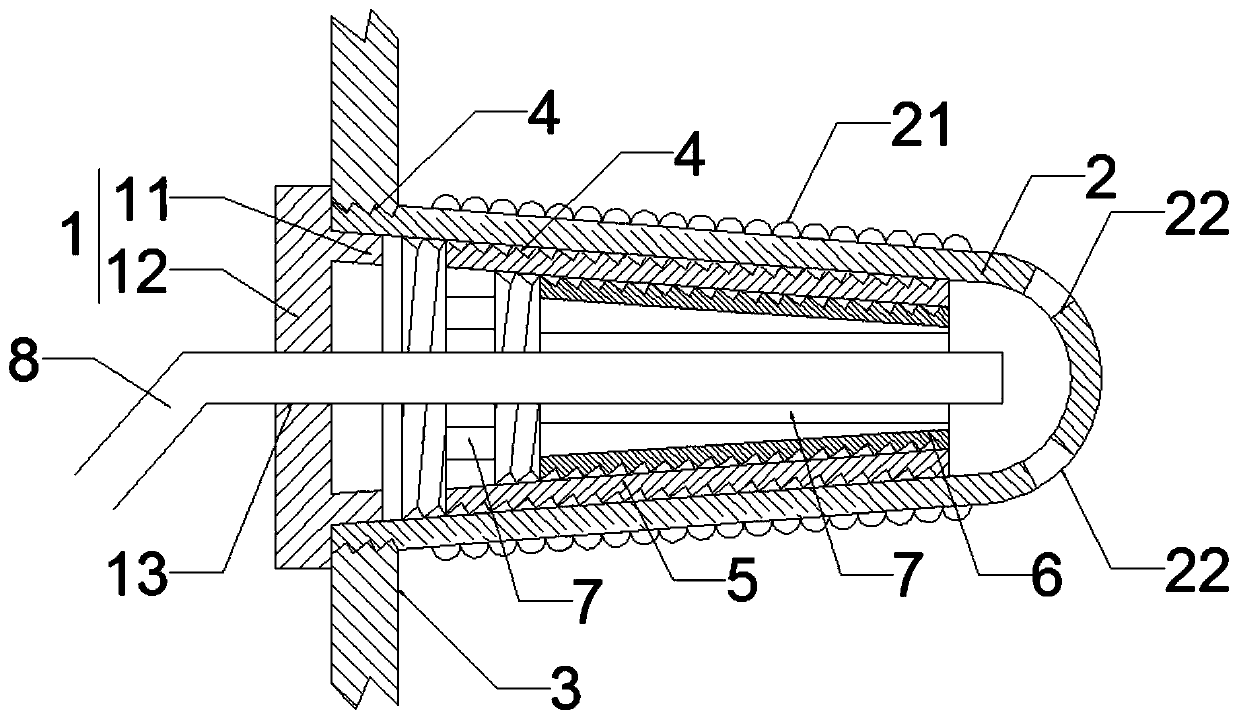

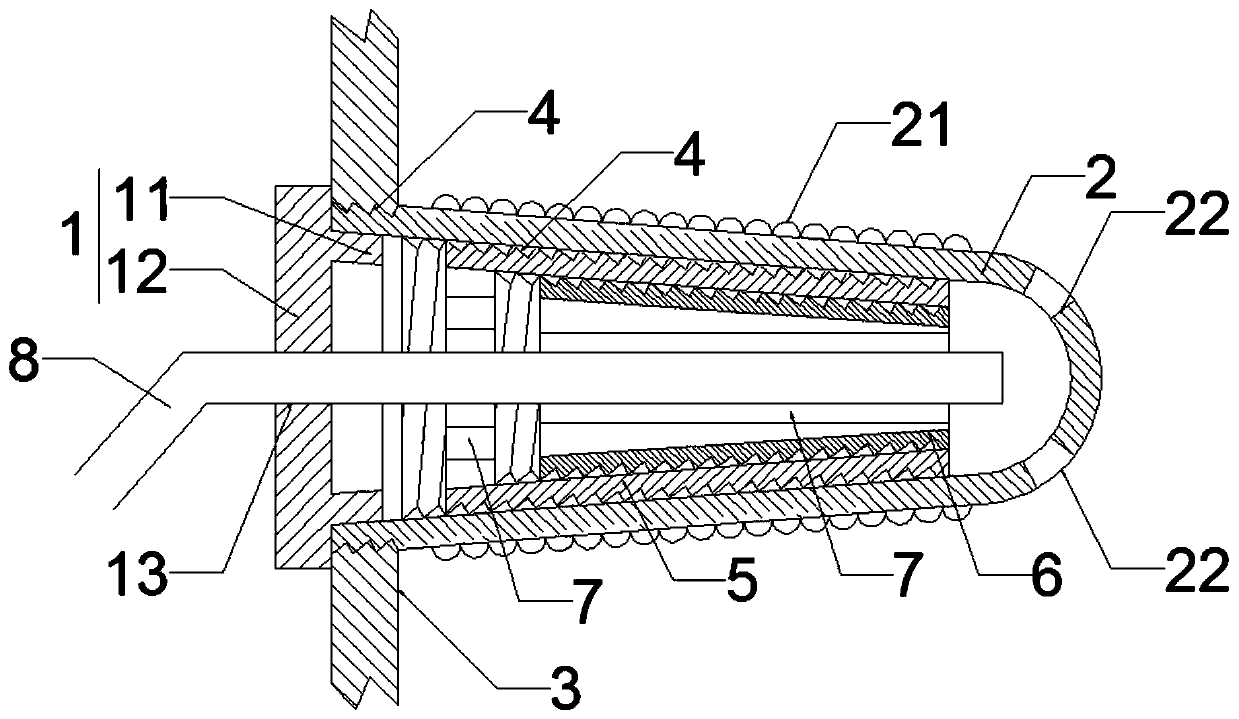

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] Such as figure 1 As shown, the onion head peeling machine uses a contact which includes a fastening ring and a contact rod 2; the contact rod 2 is made of silica gel, and the outer surface of the bottom of the contact rod 2 is provided with threads 4; the middle part and the upper outer surface of the contact rod are provided with Several annular protrusions 21; the top of the stem is a spherical surface; the interior of the stem 2 is hollow; the fastening ring is a T-shaped rubber plug 1, and the diameter of the plug seat 11 is 2 mm larger than the hollow diameter of the stem 2, and the plug cap 12 is larger than the stem 2 the diameter of the bottom;

[0024] The feeler bar 2 is installed in the peeling machine by the screw thread 4 at the bottom; The use of silicone material ensures the size of the friction force and is non-toxic and safe. The combination of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com