Automatic punching machine

An automatic punching and punching technology, which is applied in the field of pipe fittings processing, can solve problems such as large tolerances, low production efficiency, and broken stamping components, and achieve the effects of improving work efficiency, reducing labor intensity, and reducing manual operation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

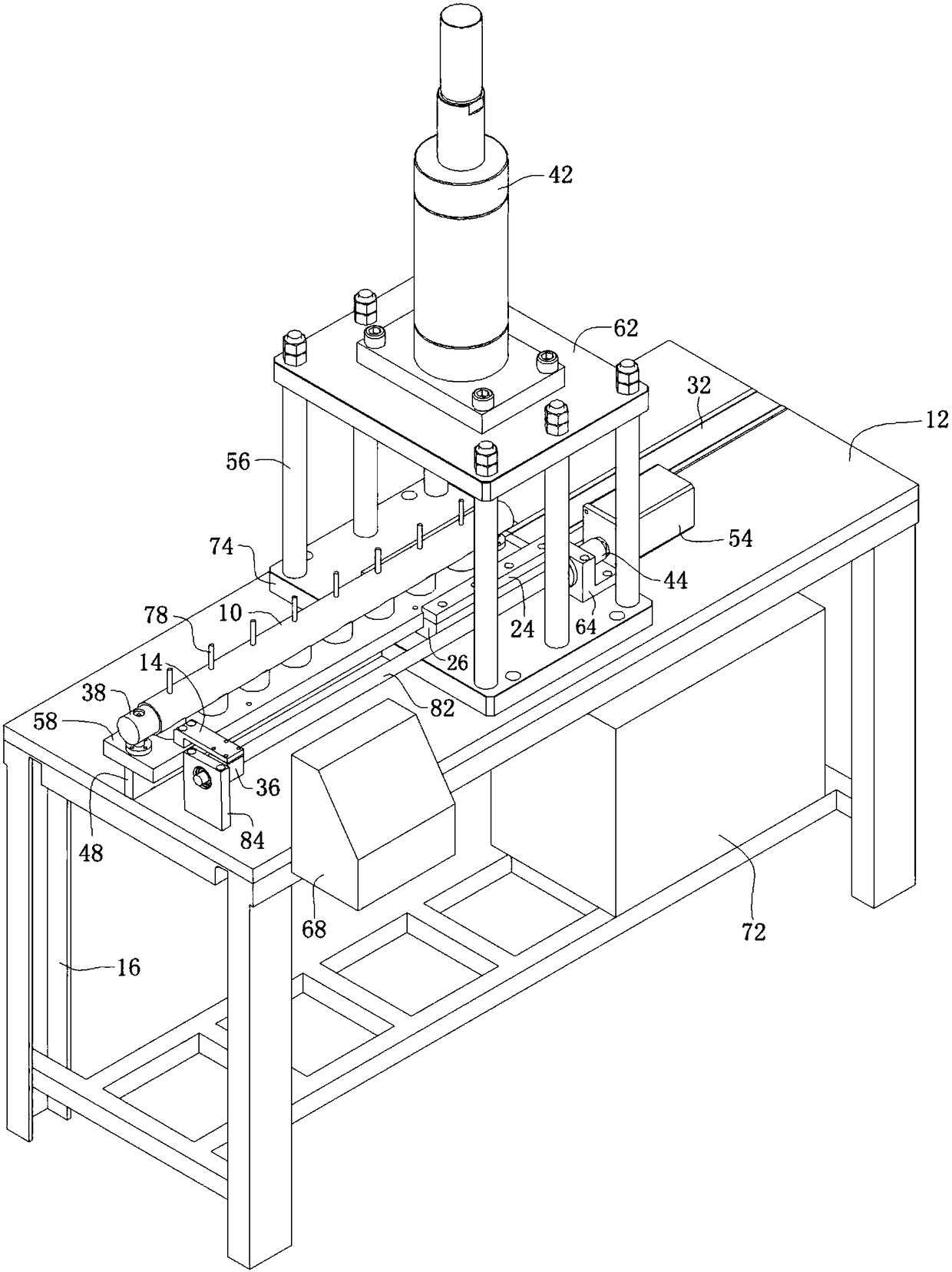

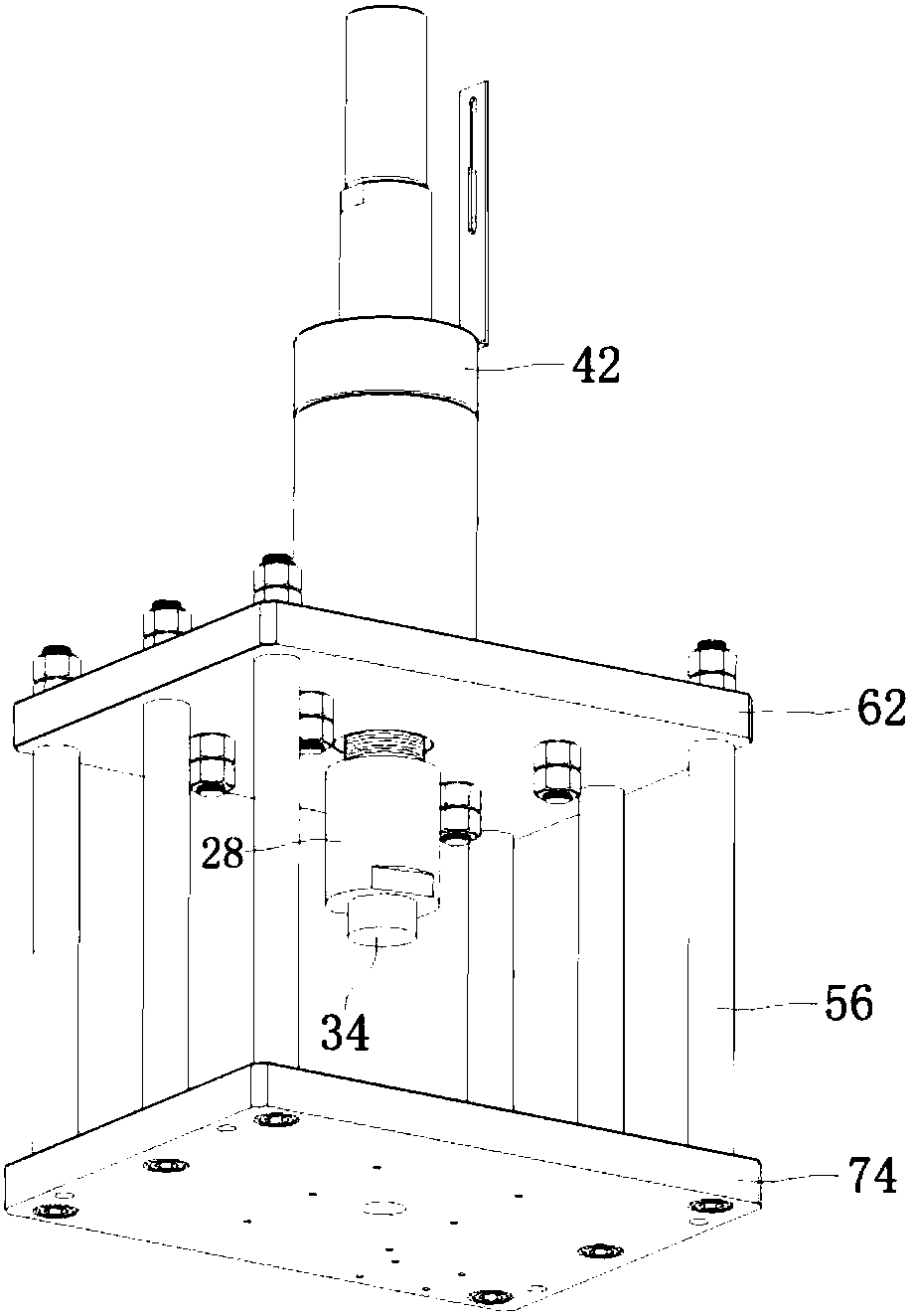

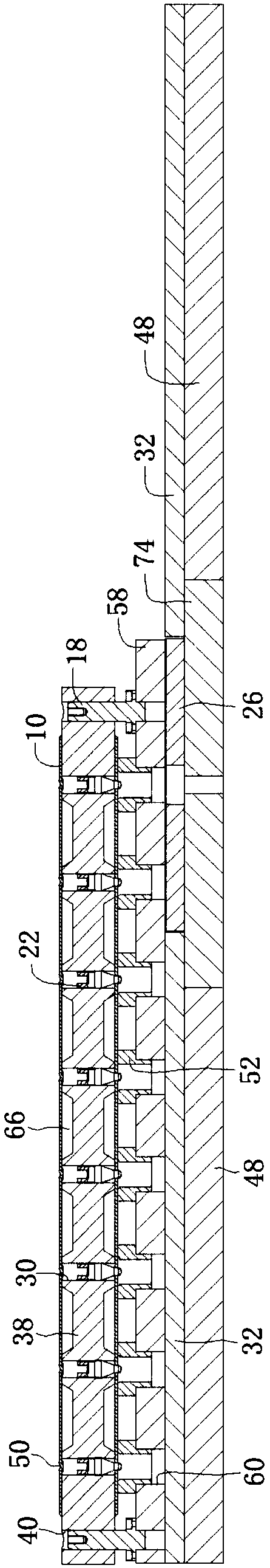

[0021] Specific reference figure 1 , the present invention comprises a square workbench support 16 and a panel 12 fixed thereon, the oil cylinder support includes a column 56 and a mounting panel 62 connected thereto, the mounting panel 62 is provided with an oil cylinder 42, and the column 56 is fixed on the panel 12 superior. Preferably but not necessarily, a bottom plate 74 is disposed between the column 56 and the panel 12 . The cylinder 42 is connected to the pressure head 34 through a connection head 28 passing through the mounting panel 62 . One end of the punch positioning column 38 is arranged below the pressure head 34. The punch positioning column 38 is roughly cylindrical and has an outer contour suitable for being inserted into the pipe 10. Through holes 30 are equidistantly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com