Mounting pylon for aircraft engine, assembly of aircraft, and air craft

A hanger and aircraft technology, applied to the layout/installation of power devices, aircraft parts, power devices on aircraft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

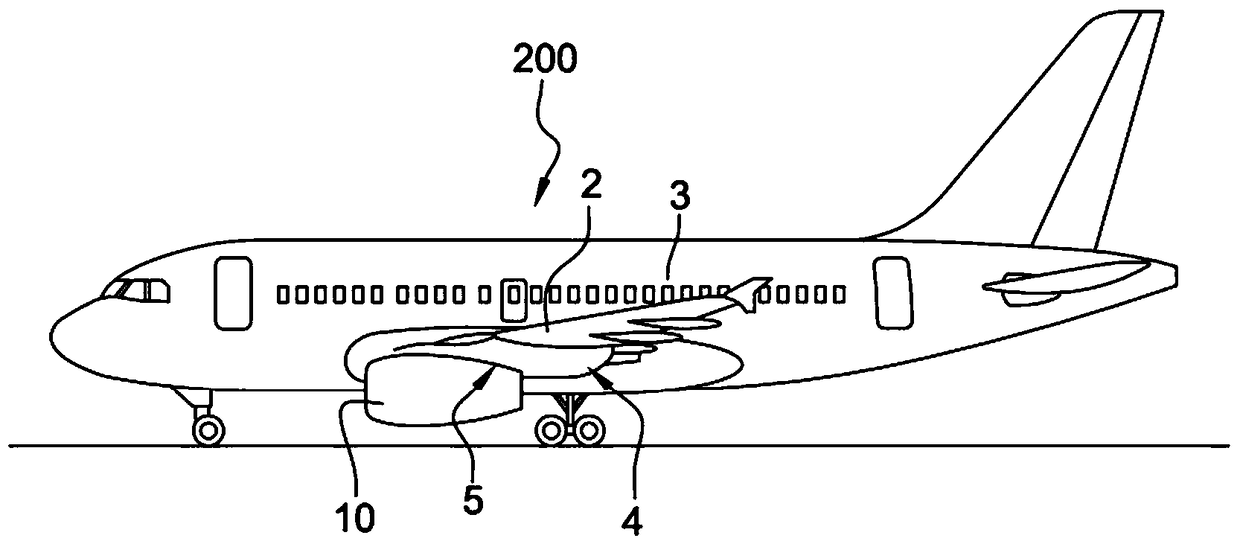

[0045] figure 1 Shown is an aircraft 200 comprising a fuselage 3 to which two wings 2 are fastened ( figure 1 Only one wing is shown). These wings 2 are an integral part with several components 5 that are specific to the invention and will be explained below. Generally, each assembly 5 comprises a wing element (in this case a wing 2 or wing section 2 ), an engine mounting pylon 4 and means for mounting the pylon on the wing. Assembly 5 is intended to carry an engine 10, preferably a twin-flow, twin-shaft engine, such as a jet engine.

[0046] Traditionally, the engine 10 is suspended below the wing 2 . Nevertheless, the invention also covers other solutions in which the engine is located above the wing, or even carried by another wing element, such as a vertical or horizontal tail or a rudder.

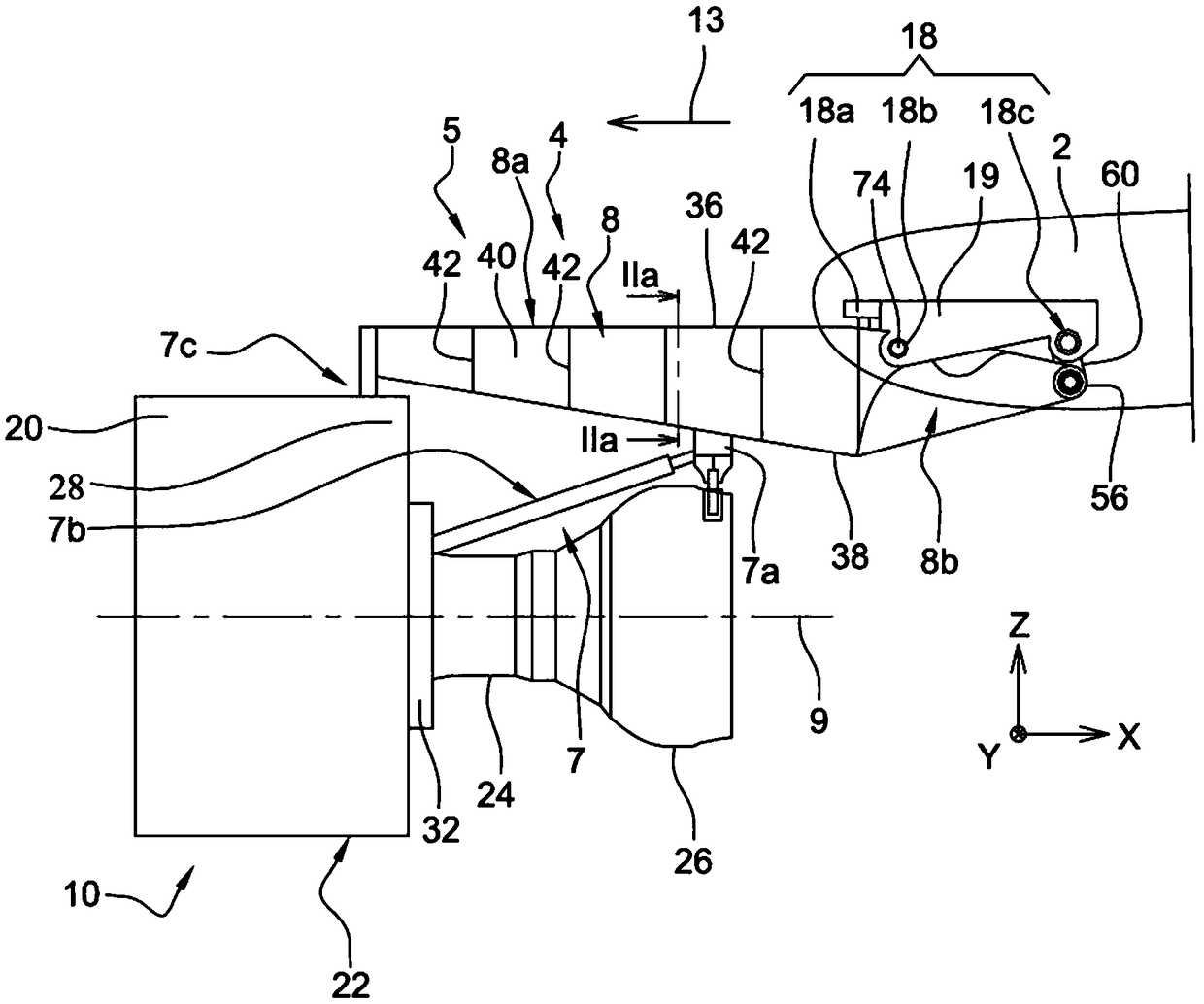

[0047] In all the following descriptions, by convention, the X direction corresponds to the longitudinal direction of the pylon 4, which can also be considered similar to the longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com