Automatic voltage and internal resistance tester

A technology of internal resistance testing and automatic voltage, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low working efficiency and achieve high working efficiency and reasonable and effective classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

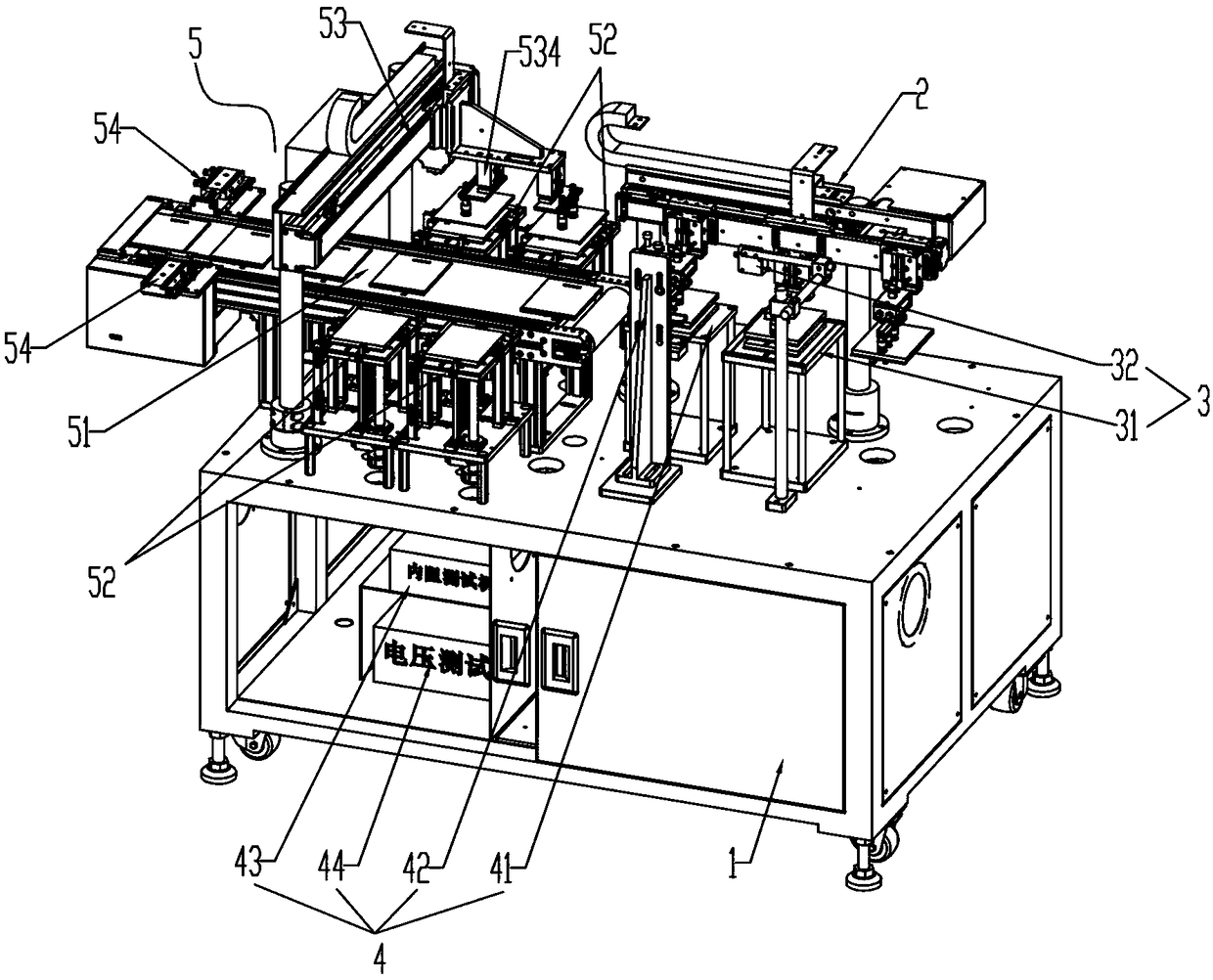

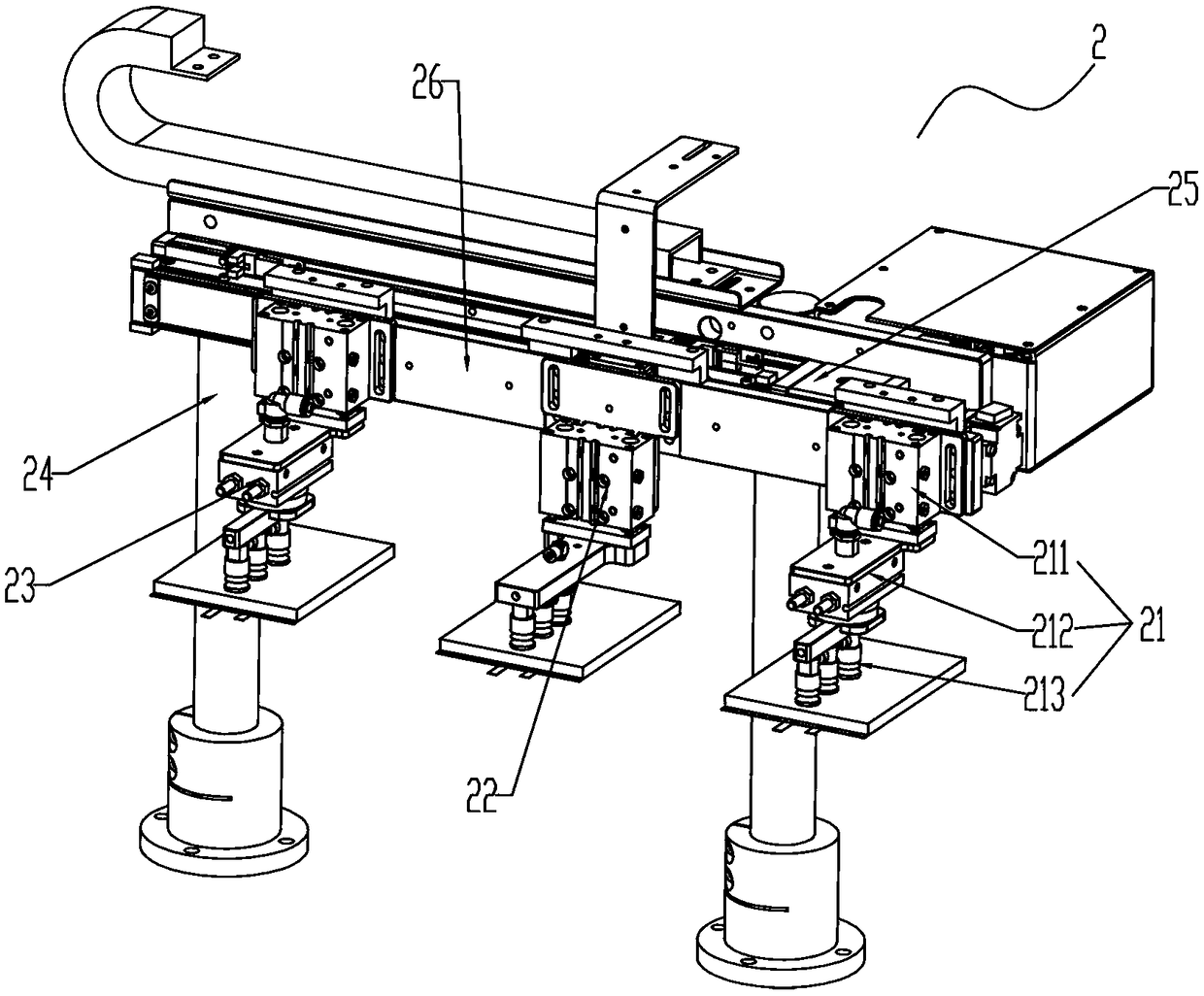

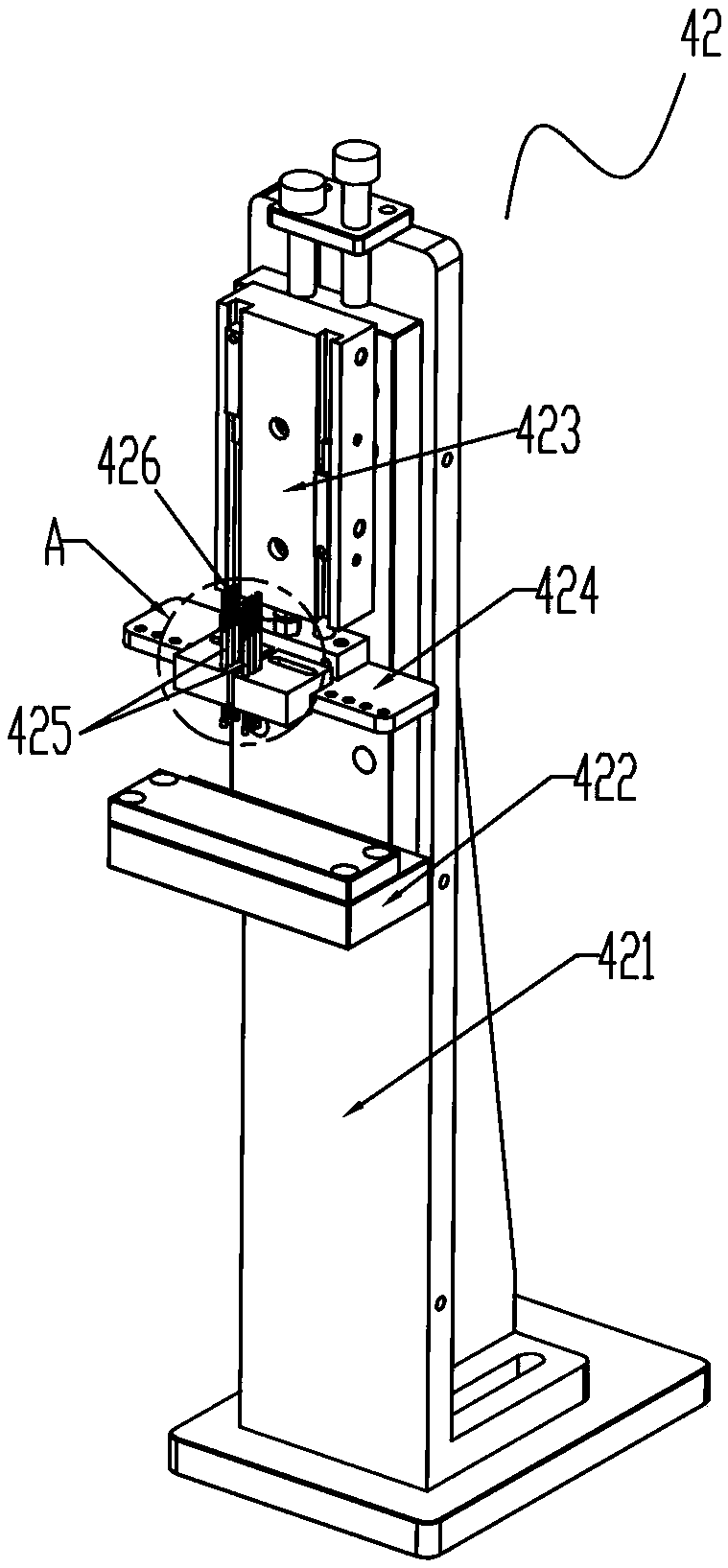

[0023] Such as Figure 1-7 As shown, an automatic voltage internal resistance testing machine includes a box body 1 and a three-link manipulator 2 installed on the box body 1, a code scanning test device 3, an internal resistance voltage test device 4 and a blanking mechanism 5; The interlocking manipulator 2 includes a loading manipulator 21, a transfer manipulator 22, and an unloading manipulator 23 that are installed in the same X-axis direction from right to left and can move along the X-axis direction at the same time; 22 below the first battery placement frame 31, and the code scanning camera 32 erected on the first battery placement frame 31; the internal resistance voltage test device 4 is arranged on the left side of the code scanning test device 3; the unloading mechanism 5 Including the unloading conveyor belt 51 arranged on the left side of the internal resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com