Pure-vertical-fiberfill molded cup and production method thereof

A cotton mold cup and mold cup technology are applied in the field of pure vertical cotton mold cups and the preparation of the mold cups, which can solve the problems of easy deformation, affecting the content of the cup, easy delamination, etc. Good comfort and small direct contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

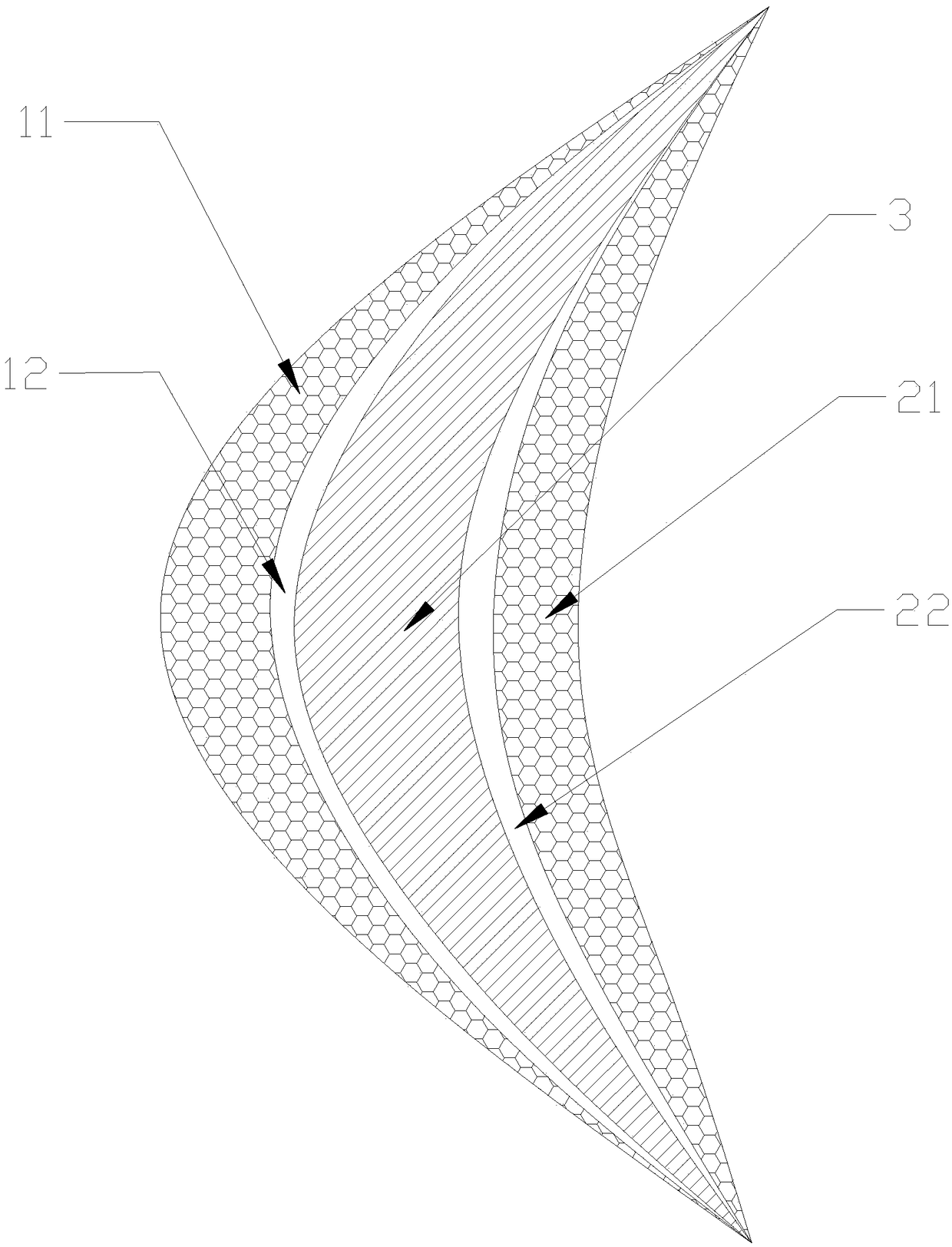

[0033] Such as figure 1 As shown, a pure cotton mold cup in this embodiment includes a first cotton layer 11 and a second cotton layer 21 and a mesh between the first cotton layer 11 and the second cotton layer 21 , There is a first glue layer between the mesh yarn and the first standing cotton layer 11 , and there is a second glue layer between the mesh yarn and the second standing cotton layer 21 .

[0034] The mesh includes a first mesh 12 attached to the first pile layer 11 and a second mesh 22 attached to the second pile layer 21 . That is, there is a first glue layer between the first mesh yarn 12 and the first stand cotton layer 11 , and there is a second glue layer between the second mesh yarn 22 and the second stand cotton layer 21 . And the area of the first mesh yarn 12, the first adhesive layer is identical with the area of the first standing cotton layer 11, the area of the second mesh yarn 22, the second adhesive layer is identical with the second erect co...

Embodiment 2

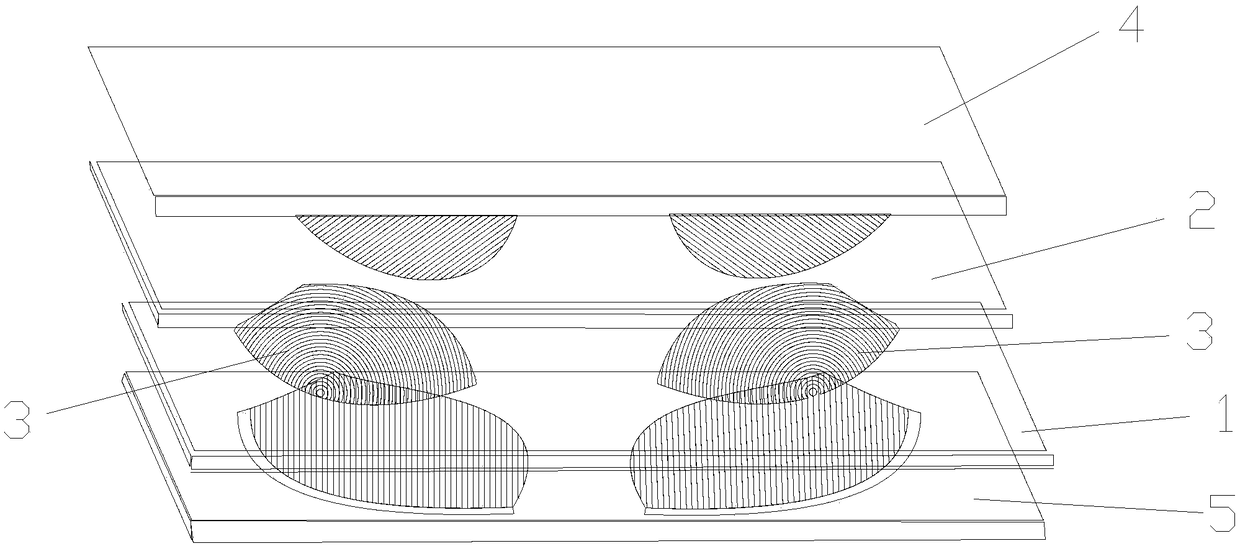

[0044] Such as Figure 1-4 As shown, the present embodiment provides a kind of preparation method of pure standing foam mold cup, specifically comprises the following steps:

[0045] Step S1: Design

[0046] Design the style of the mold cup.

[0047] Step S2: Open the mold

[0048] Set up two sets of thermoplastic molds according to the designed mold cup style, shape and thickness, including a set of hot pressing mold and a set of cold pressing mold. Die 5.

[0049] Step S3: Prepare materials

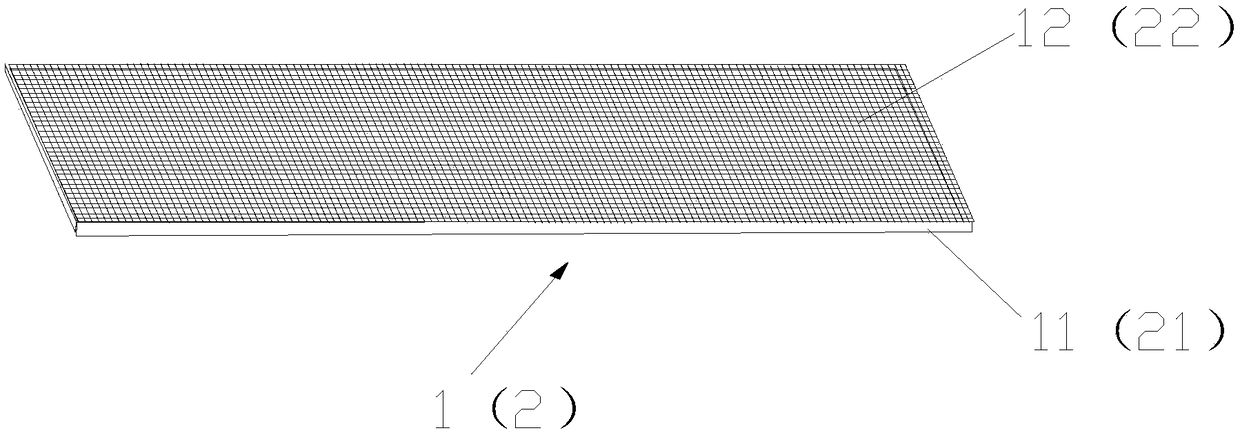

[0050] According to the designed mold cup style, prepare the first vertical cotton layer 11, the second vertical cotton layer 21, the first mesh yarn 12, the second mesh yarn 22 and the vertical cotton core 3.

[0051] Step S4: Fitting

[0052] The mesh is attached to the standing cotton layer to form the first mesh 12 and the first standing cotton layer 11 that are bonded together, that is, the first composite material 1 and the second mesh 22 and the second vertical fiber that a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com