Conveying device for high-viscosity material low in flowing property and application method

A technology of flow performance and conveying device, applied in the direction of injection device, liquid injection device, etc., can solve the problems of high viscosity, high solid material conveying difficulty, high viscosity material poor fluidity, difficult to replenish materials in time, etc., to reduce gas. The effect of acupuncture phenomenon, accurate temperature measurement, and avoiding frequent alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

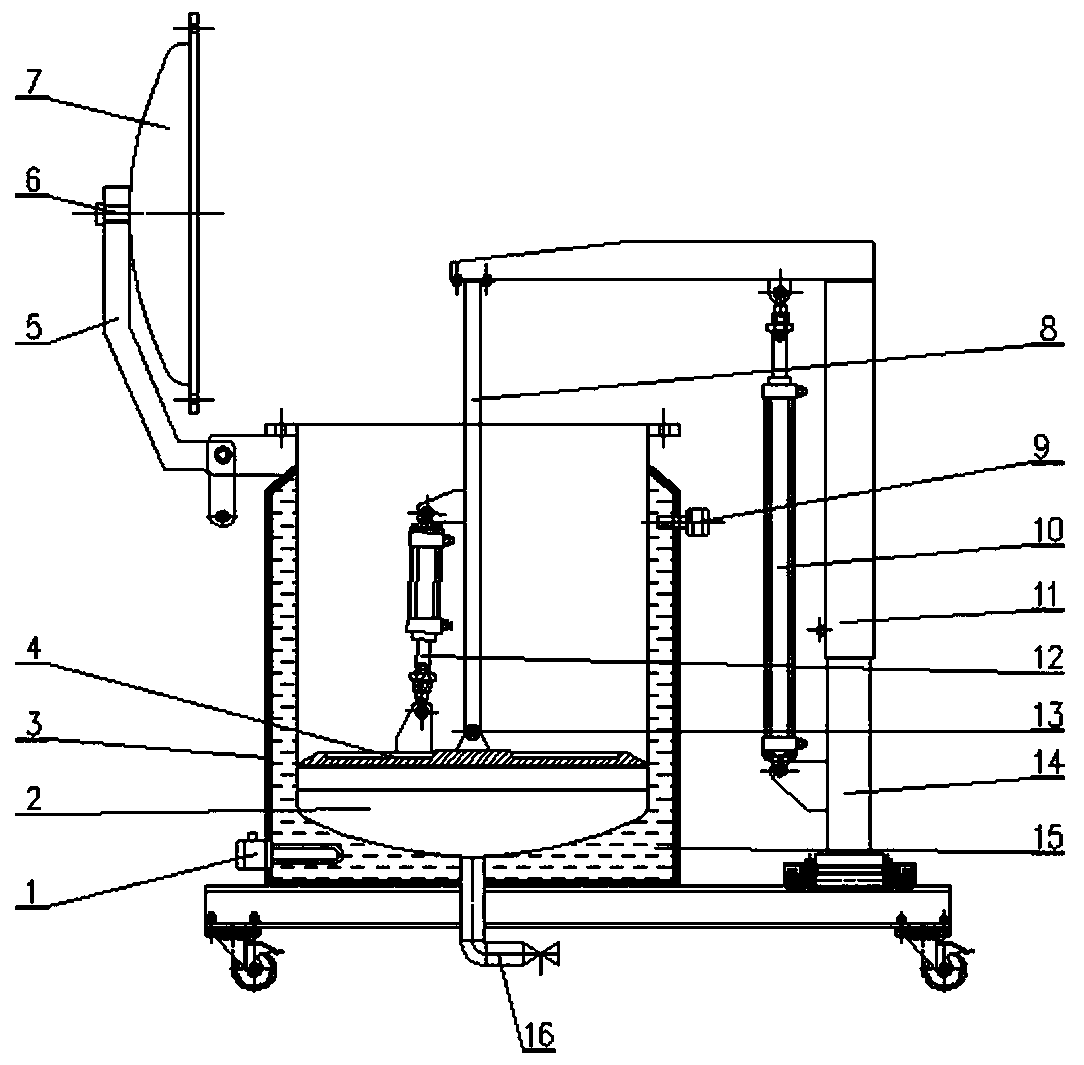

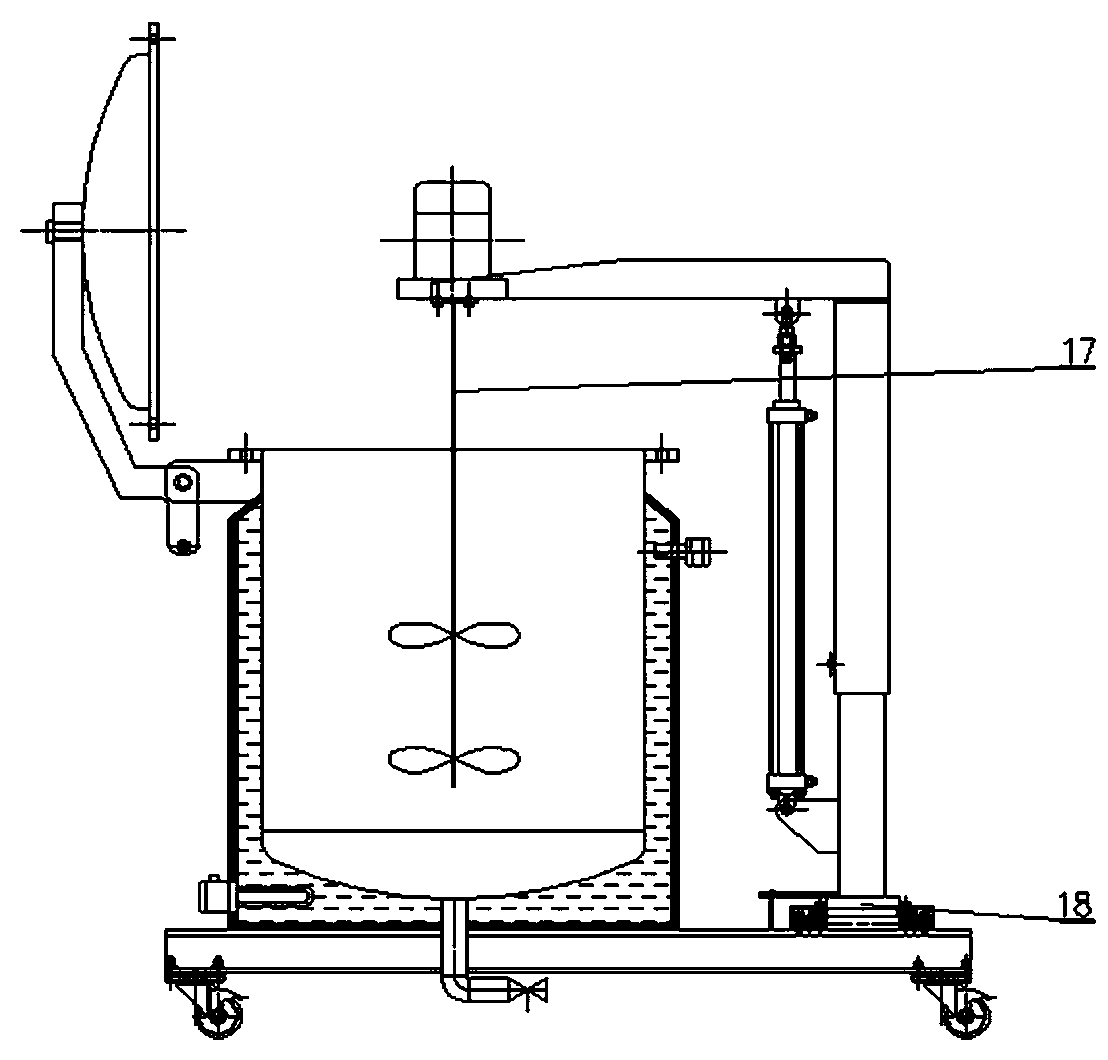

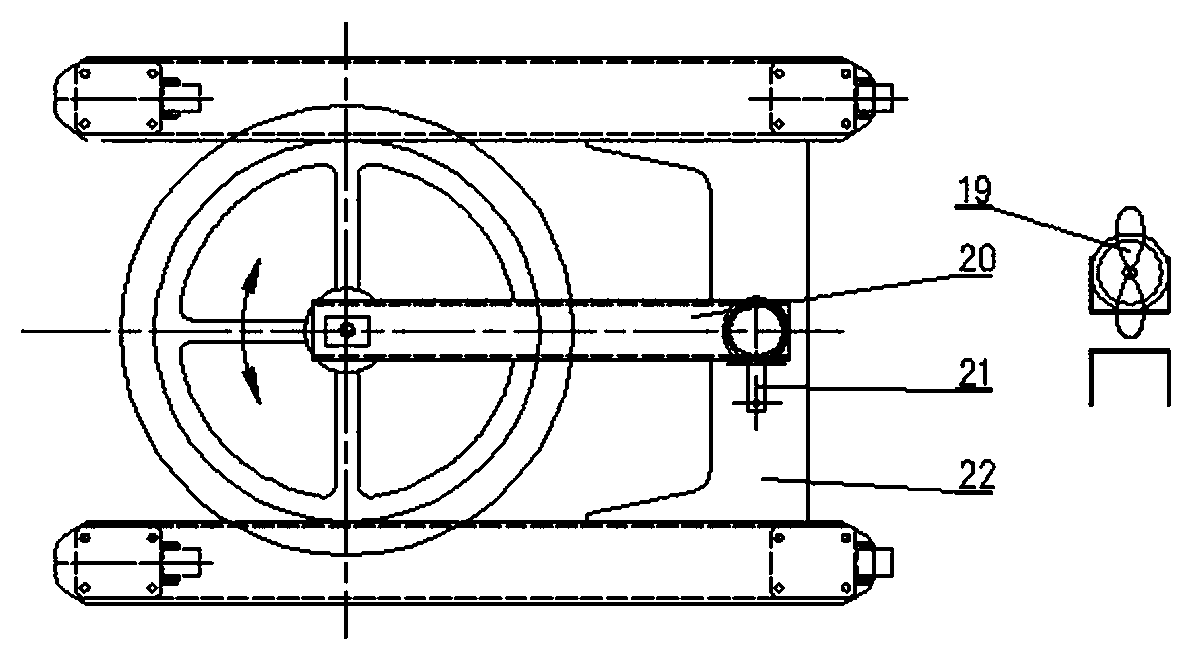

[0024] Such as figure 1 As shown, a conveying device for highly viscous materials with low fluidity is different from the prior art in that the conveying device includes a material storage container and a movable upper cover matched therewith, and one side of the material storage container A lifting device is provided, the lifting device includes a rotatable beam, the beam includes a disc-shaped tooling support, and a stirring module and a feeding module are arranged under the tooling support.

[0025] Preferably, the size of the mixing module and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com