Ultrasonic cleaning machine for preparing optical lenses

An optical lens and ultrasonic technology, applied in the field of optical lenses, can solve the problems of reducing the cleaning effect, affecting the cleaning and cleaning effect, unable to guarantee the cleaning effect of residual dirt, etc., so as to ensure the cleaning effect, ensure the treatment effect, and avoid secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

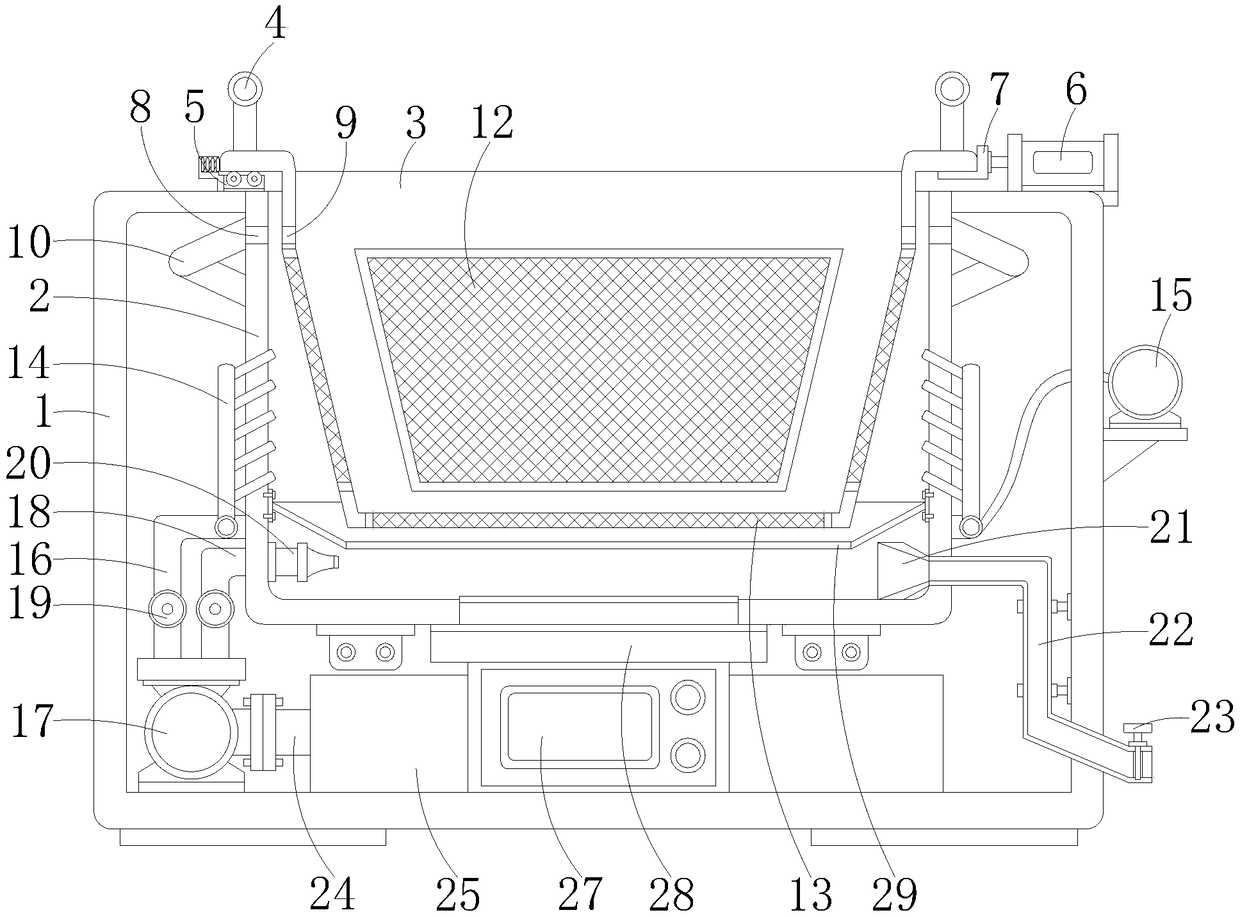

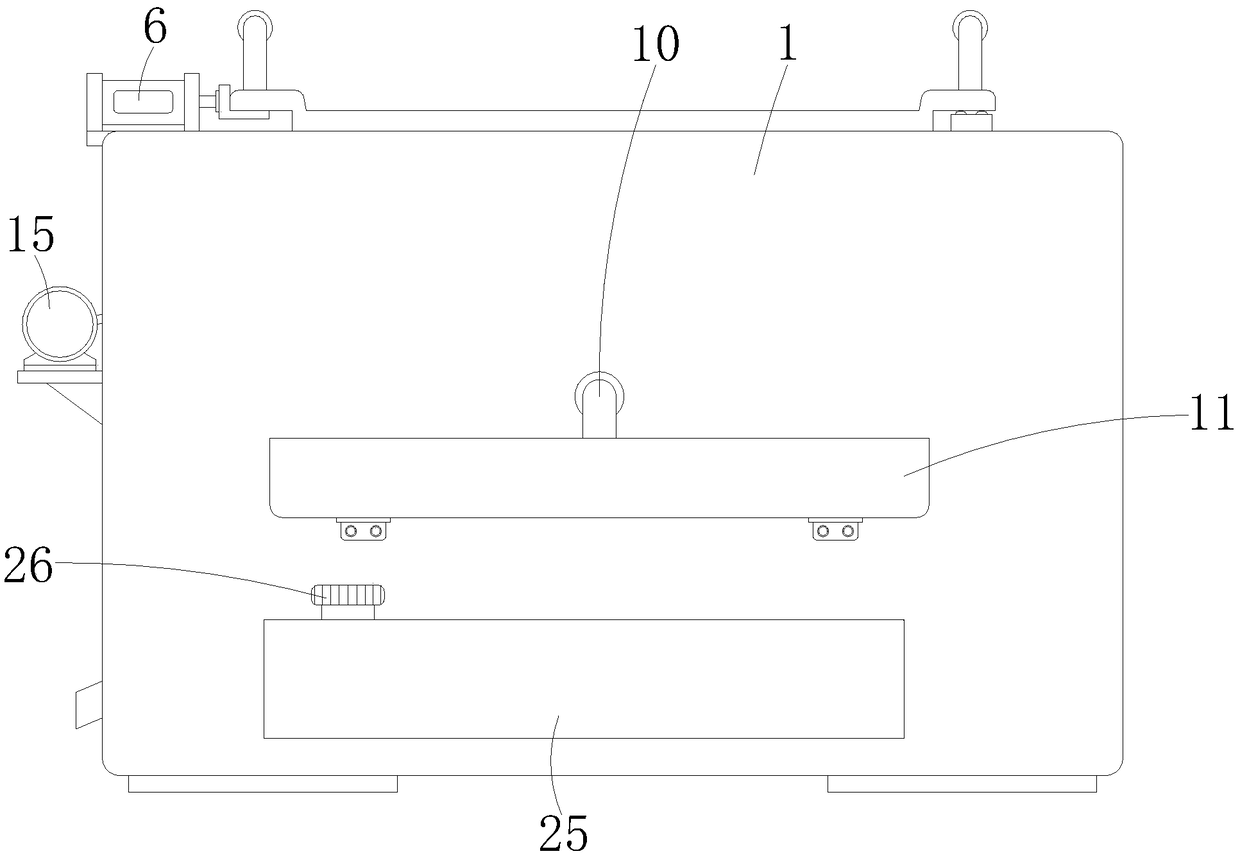

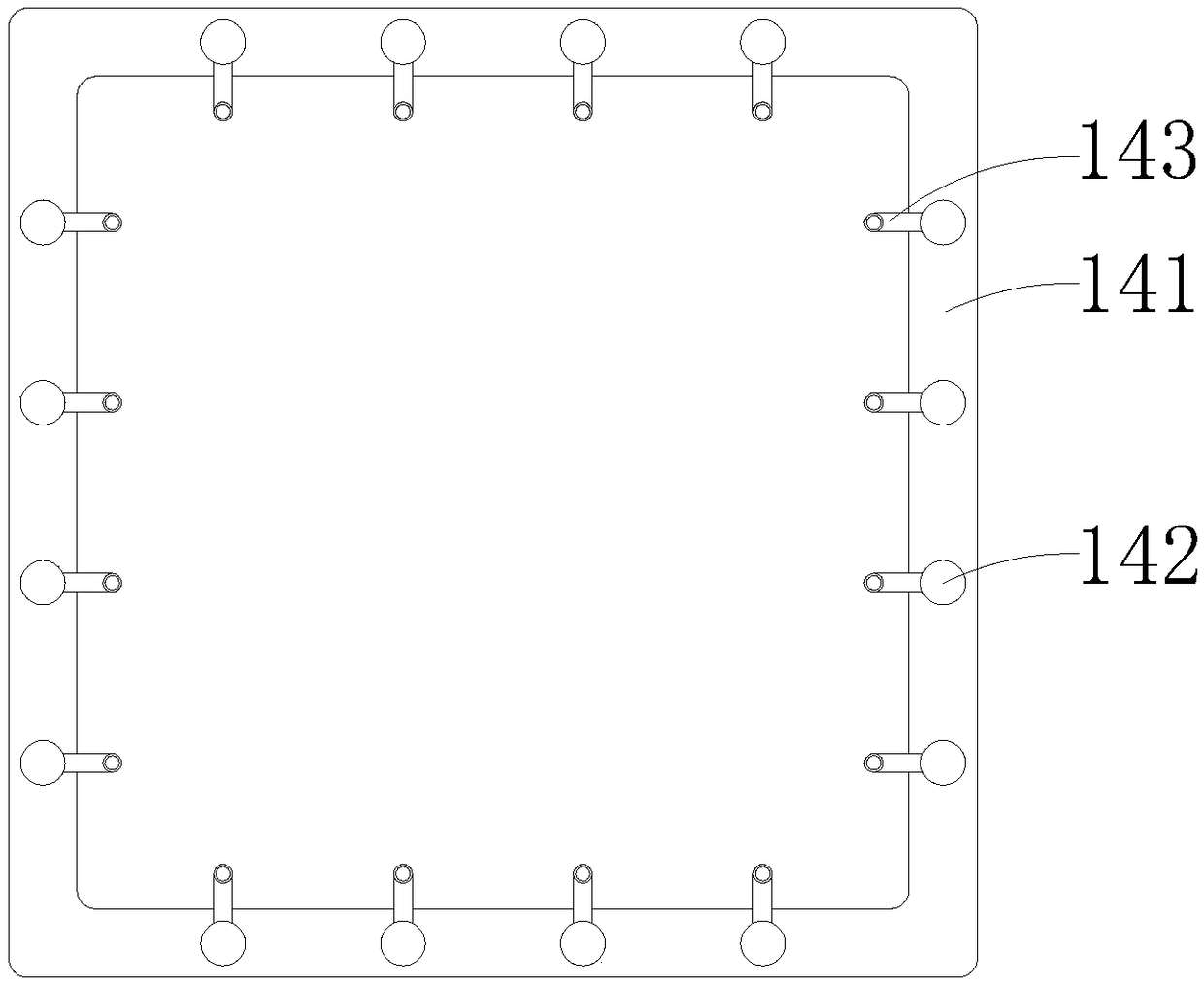

[0026] see Figure 1-4, the present invention provides a technical solution: an ultrasonic cleaning machine for preparing optical lenses, including a body 1, a cleaning tank 2, a placement box 3, a sliding member 5, a cylinder 6, a bracket 7, a first overflow tank 8. The second overflow tank 9, the tee pipe 10 and the liquid collection tank 11, the cleaning tank 2 is fixedly installed in the middle of the top of the body 1, and the bottom of the cleaning tank 2 extends to the inner cavity of the body 1, and the box 3 is set In the cleaning tank 2, the middle parts of the left and right sides of the top of the storage box 3 are fixedly connected with a handle 4, and the handle 4 is sleeved with a non-slip sleeve, and the top of the left side of the storage box 3 is slidably connected to the sliding member 5. And the bottom of the sliding member 5 is fixedly connected to the left side of the top of the body 1, the cylinder 6 is fixedly installed on the right side of the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com