A mechanical gear repairing and punching auxiliary mechanism

An auxiliary mechanism and gear technology, applied in the direction of boring/drilling, drilling/drilling equipment, manufacturing tools, etc., can solve problems such as increased maintenance costs, multiple drilling, gear wear, etc., to improve work efficiency, The effect of preventing unstable deviation and reducing the damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

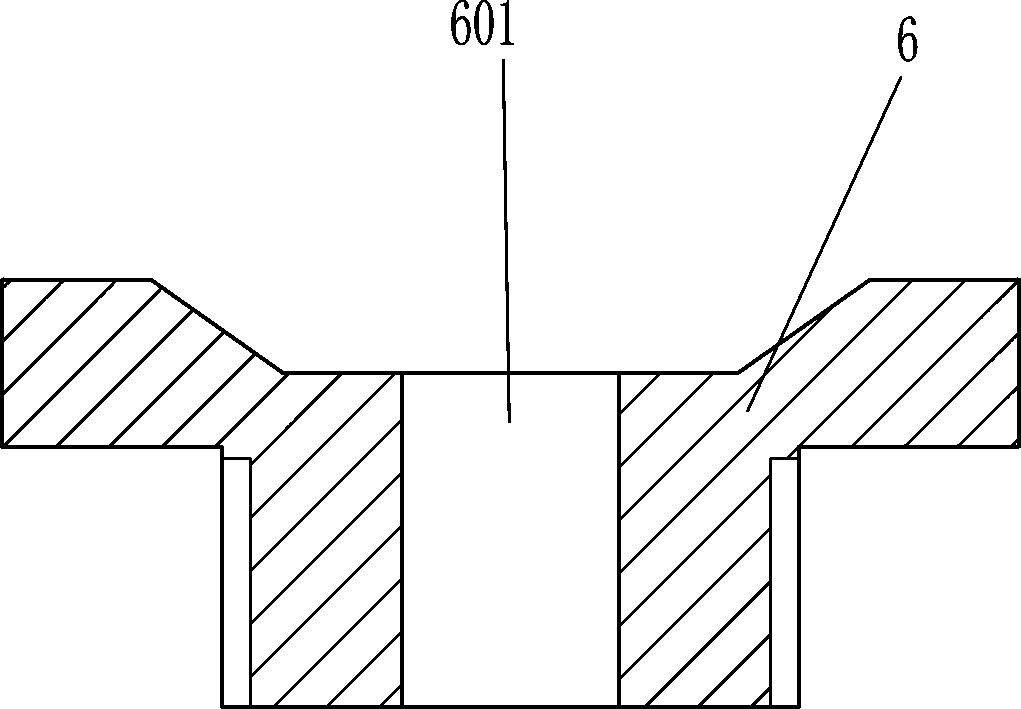

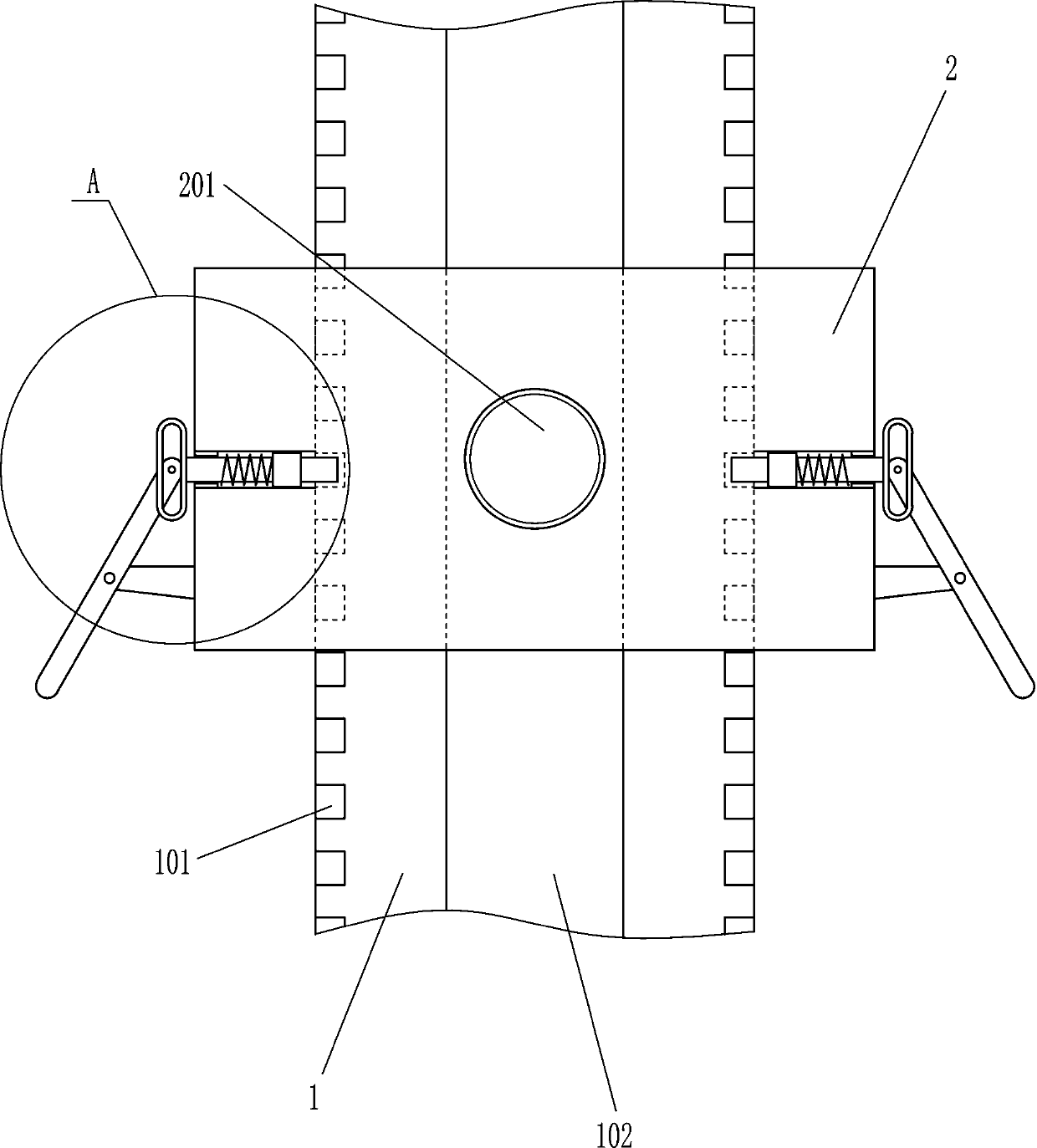

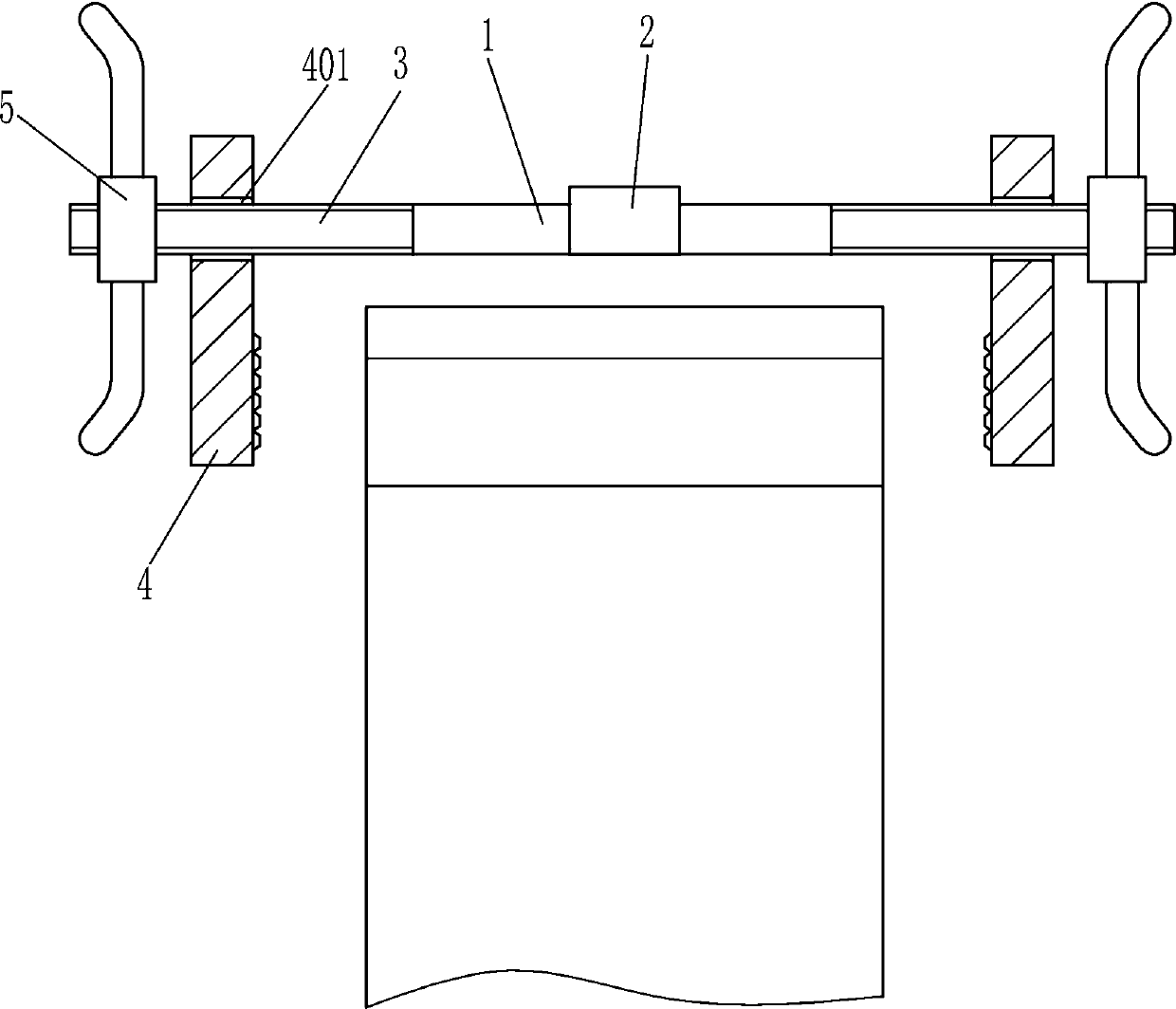

[0020] A mechanical gear repair punching auxiliary mechanism, such as Figure 1-4 As shown, it includes a guide rail 1, a screw 3, a splint 4 and a wing nut 5, the left and right sides of the guide rail 1 are provided with a screw 3, the screw 3 is provided with a splint 4 and a wing nut 5, and the left splint 4 is located on the left On the right side of the butterfly nut 5, the right splint 4 is located on the left side of the right wing nut 5, the upper part of the splint 4 has a slide hole 401, the outer end of the screw rod 3 passes through the slide hole 401, and the middle part of the guide rail 1 has a through hole 102.

Embodiment 2

[0022] A mechanical gear repair punching auxiliary mechanism, such as Figure 1-4 As shown, it includes a guide rail 1, a screw 3, a splint 4 and a wing nut 5, the left and right sides of the guide rail 1 are provided with a screw 3, the screw 3 is provided with a splint 4 and a wing nut 5, and the left splint 4 is located on the left On the right side of the butterfly nut 5, the right splint 4 is located on the left side of the right wing nut 5, the upper part of the splint 4 has a slide hole 401, the outer end of the screw rod 3 passes through the slide hole 401, and the middle part of the guide rail 1 has a through hole 102.

[0023] It also includes a guide block 2, which slides on the guide rail 1 and is provided with a threaded hole 201 in the middle of the guide block 2. The threaded hole 201 is located directly above the through hole 102, and there are grooves 101 on the front and rear sides of the guide rail 1. .

Embodiment 3

[0025] A mechanical gear repair punching auxiliary mechanism, such as Figure 1-4 As shown, it includes a guide rail 1, a screw 3, a splint 4 and a wing nut 5, the left and right sides of the guide rail 1 are provided with a screw 3, the screw 3 is provided with a splint 4 and a wing nut 5, and the left splint 4 is located on the left On the right side of the butterfly nut 5, the right splint 4 is located on the left side of the right wing nut 5, the upper part of the splint 4 has a slide hole 401, the outer end of the screw rod 3 passes through the slide hole 401, and the middle part of the guide rail 1 has a through hole 102.

[0026] It also includes a guide block 2, which slides on the guide rail 1 and is provided with a threaded hole 201 in the middle of the guide block 2. The threaded hole 201 is located directly above the through hole 102, and there are grooves 101 on the front and rear sides of the guide rail 1. .

[0027] Also include nail 203, slide block 204, spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com