Machining method of large-sized large-tapered half-enclosure thin-walled cast steel housing

A kind of mechanical processing and large taper technology, which is applied in the field of milling machining, can solve the problems of low processing efficiency, easy breakage of tools, and poor rigidity of parts, so as to achieve the effects of improving life and processing efficiency, reasonable process methods, and increasing stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

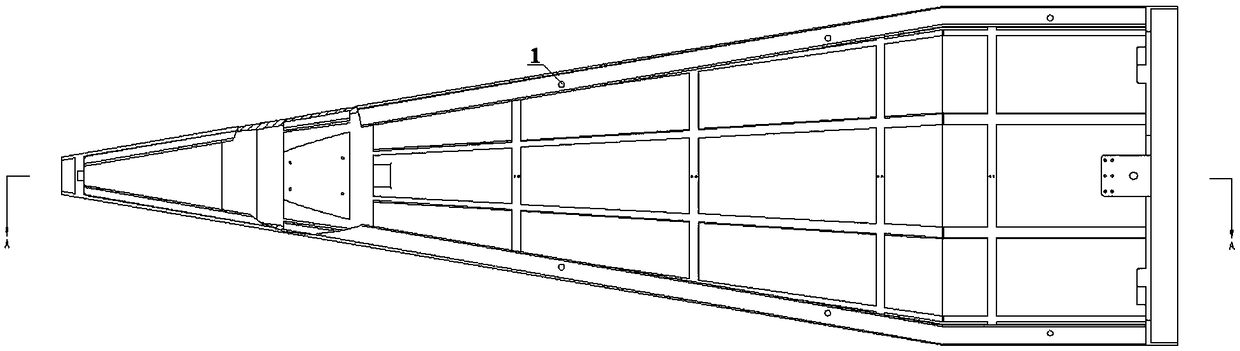

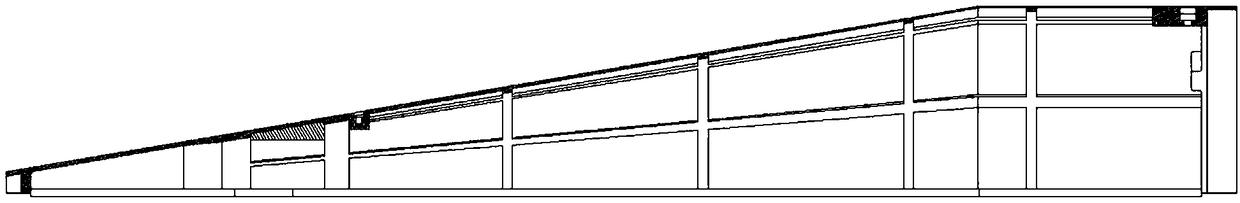

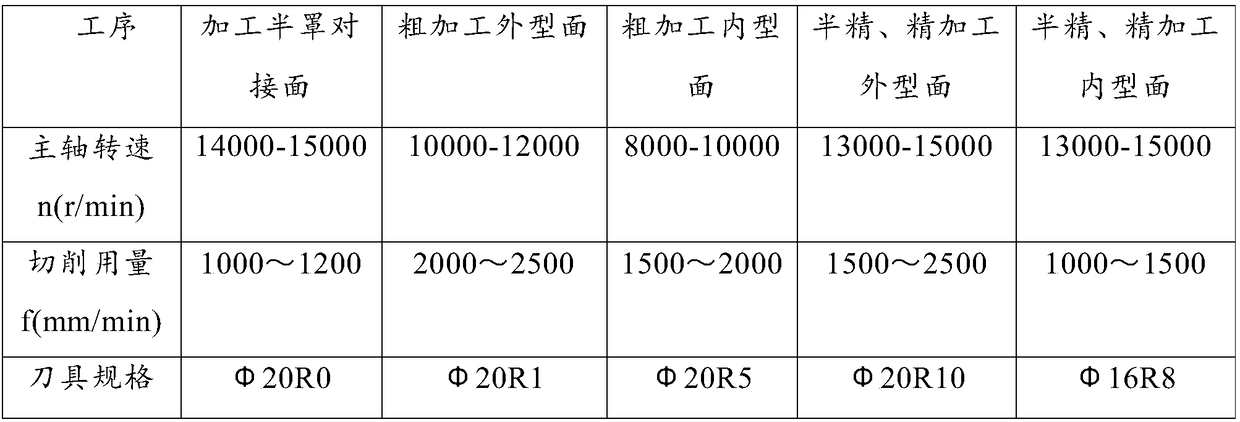

[0046] The embodiment of the present application provides a machining method for a large-scale large tapered half-covered thin-walled cast steel shell, which solves the problem of poor rigidity of parts during machining, difficulty in clamping, large internal and external surface chatter, easy breakage of tools, low processing efficiency, and low product quality. It is unstable and cannot meet the requirements of use.

[0047] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical solutions of the present application. , rather than limiting the technical solutions of the present application, the embodiments of the present application and the technical features in the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com