Vulcanizing tool for rubber product with framework

A technology for rubber products and vulcanizers, applied in coating and other directions, can solve the problems of time waste, temperature reduction, time-consuming and laborious, and achieve the effect of improving production efficiency and safety, avoiding high-temperature burns, and improving vulcanization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

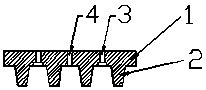

[0016] figure 1 Among them, four rows of press-in piles 2 are arranged at the bottom of the upper platen 1, and connection holes 3 for connecting with vulcanizer bolts are provided between two adjacent rows of press-in piles 2 on the upper platen 1 . The upper platen 1 is also provided with a first glue injection hole 4 matching the glue injection hole on the vulcanizer.

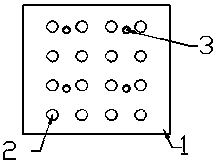

[0017] figure 2 Among them, there are four rows of press-in piles 2 on the upper pressing plate 1, and each row is provided with four press-in piles 2. Two connection holes 3 for bolt connection with vulcanizer are provided between two adjacent rows of press-in piles 2 .

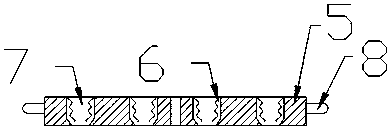

[0018] image 3 Among them, the lower plate 5 is provided with a skeleton placement hole 7 at a position corresponding to the press-in pile 2 . Circlips 6 are all provided in each frame placement hole 7 . Both sides of the lower plate 5 are provided with handles 8 . Handle 8 adopts the material that does not conduct heat. The surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com