High speed train modular floor and mounting method of modular floor

A technology for high-speed EMUs and installation methods, applied in transportation and packaging, railway car bodies, railway car body parts, etc., can solve problems such as functional defects, volatilization, and no significant effect of noise in the middle and low frequency bands, etc., to achieve Excellent heat insulation performance, vibration mitigation and noise suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

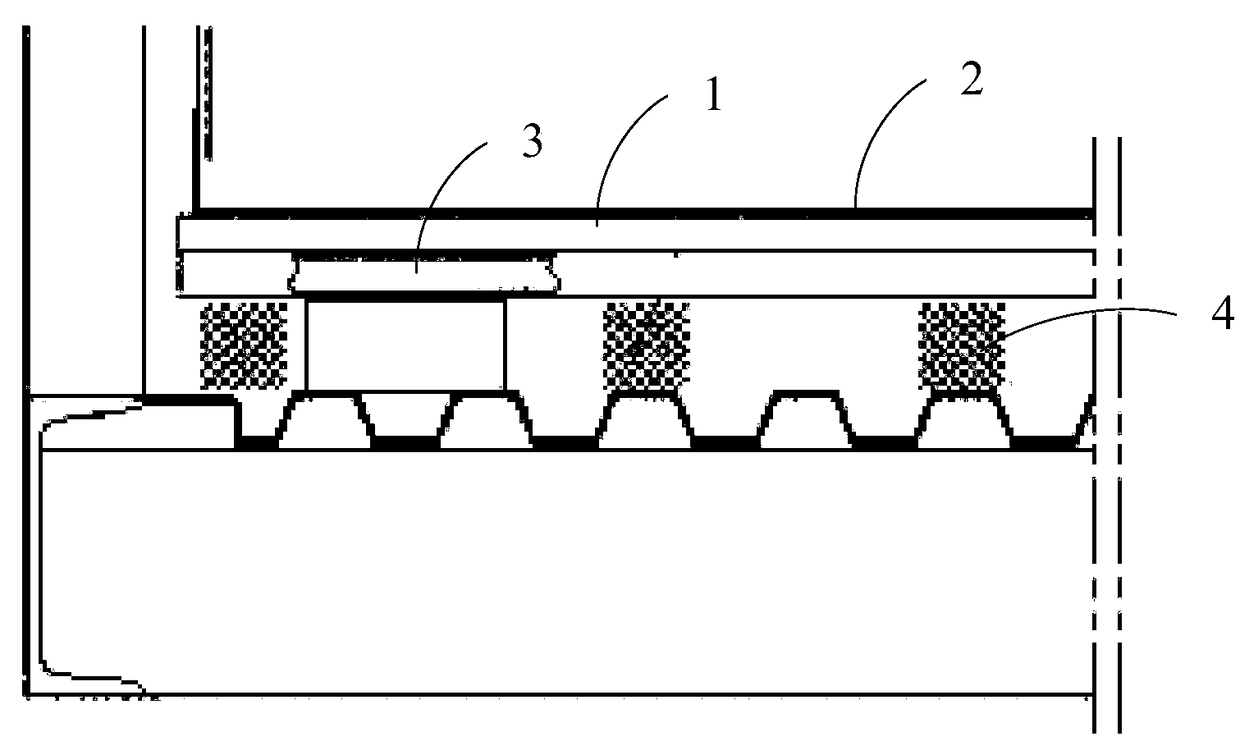

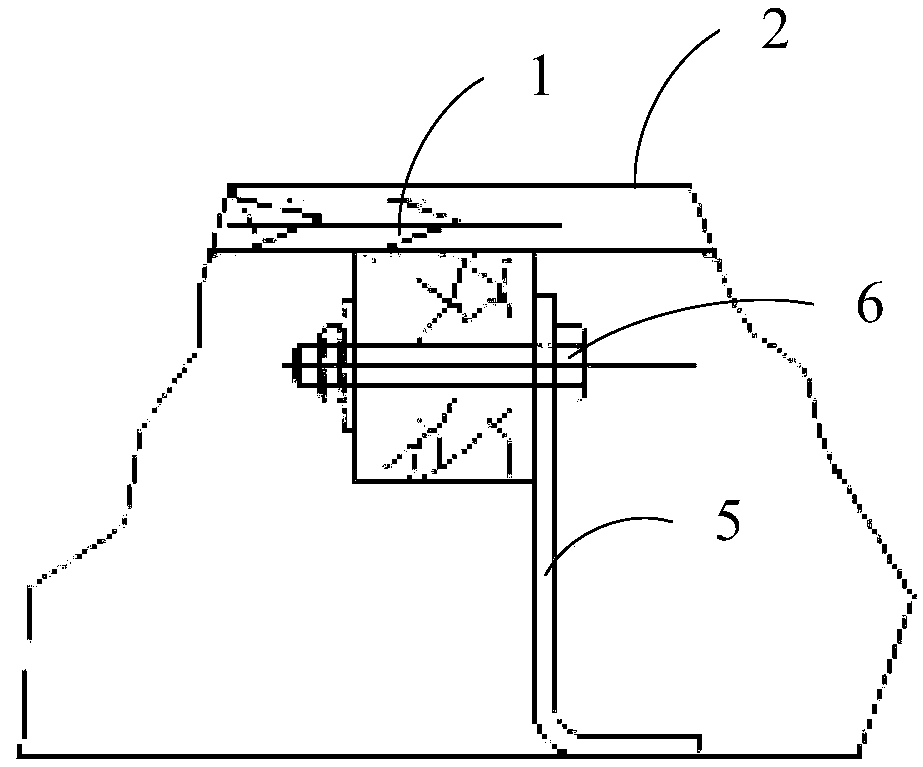

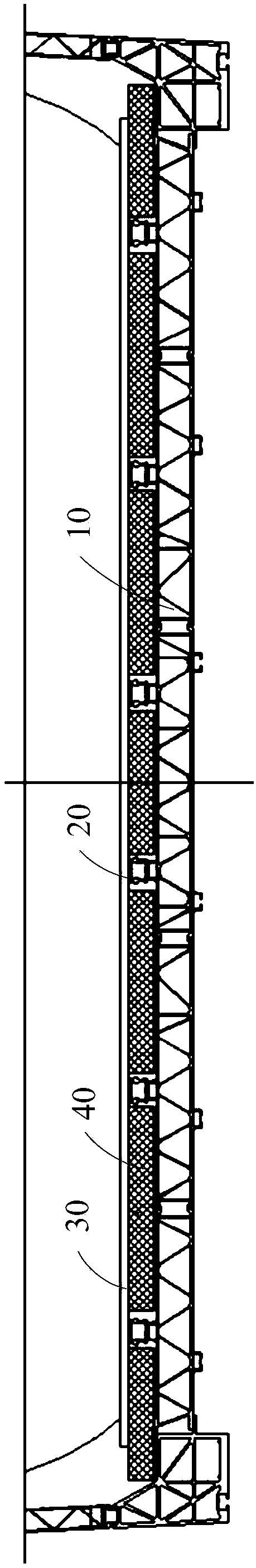

[0062] image 3 It is a schematic structural diagram of the modular floor of a high-speed EMU provided by Embodiment 1 of the present invention. Figure 4 It is a structural schematic diagram of the damping part of the modular floor of the high-speed EMU provided by Embodiment 1 of the present invention. Figure 5 It is a structural schematic diagram of the support unit of the support part of the modular floor of the high-speed EMU provided by Embodiment 1 of the present invention. Figure 6 It is a structural schematic diagram of the thermal insulation element for the modular floor of the high-speed train set provided by Embodiment 1 of the present invention.

[0063] Refer to attached image 3 to attach Figure 6 As shown, Embodiment 1 of the present invention provides a modular floor for high-speed EMUs, including a support portion 10 disposed at the bottom of the car body, a shock absorber 20 located on the support portion 10 , and a floor body 30 located on the shock a...

Embodiment 2

[0091] Figure 7 It is a schematic flowchart of the installation method of the modular floor of the high-speed EMU provided by the second embodiment of the present invention. Refer to attached Figure 7 As shown, on the basis of the first embodiment above, the second embodiment of the present invention also provides an installation method for the modular floor of the high-speed EMU. The installation method is used to install the modular floor of the high-speed EMU in the first embodiment. The installation method Include the following steps:

[0092] S1: Coating a damping layer on the outer surface of the support part of the car body;

[0093] S2: arranging a plurality of damping parts at intervals along the length direction of the vehicle body on the support part;

[0094] S3: Filling insulation pieces between adjacent shock absorbing parts;

[0095] S4: Install the floor body on the shock absorbing part and the insulation part;

[0096] S5: Obtain the measured strength p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com