A compartment layering device

A technology of layered devices and carriages, applied in the superstructure of trucks, motor vehicles, vehicle parts, etc., can solve the problems of unsmooth operation, increased operation time, slightly inclined positioning track, etc., so as to achieve smooth movement and lift Stability, weight saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

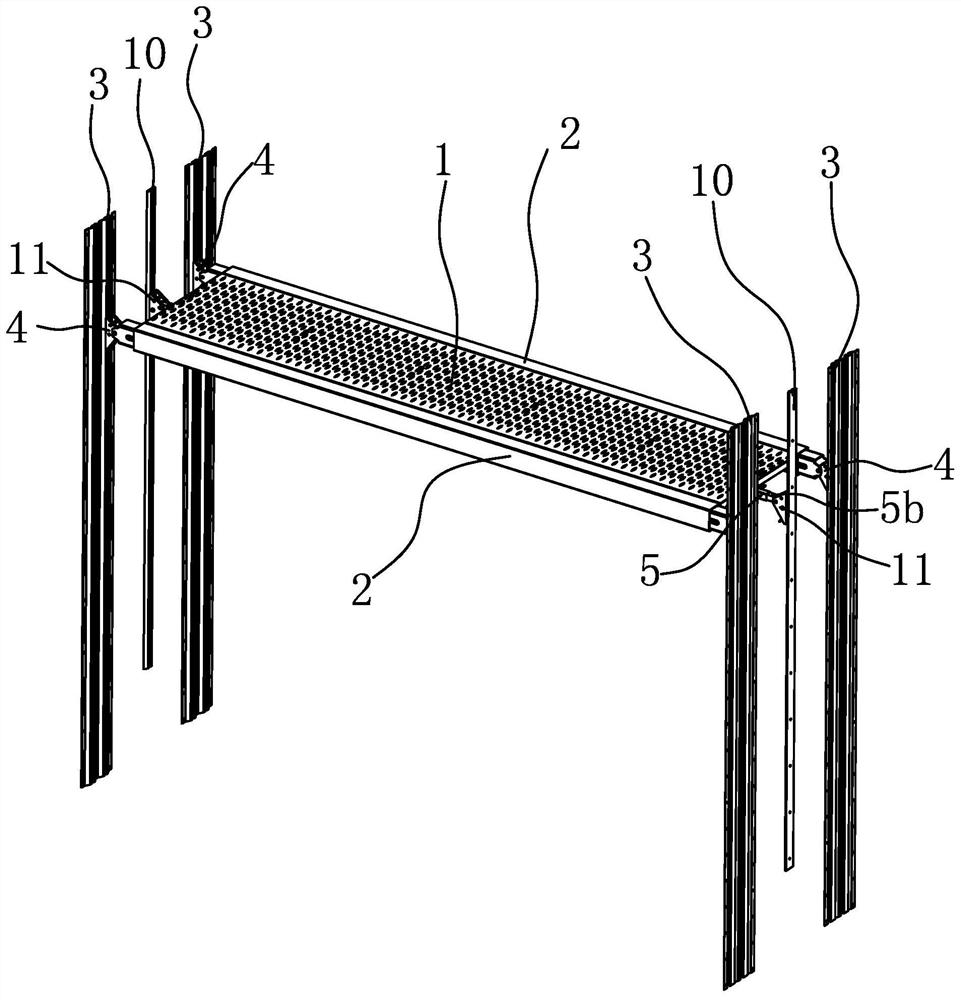

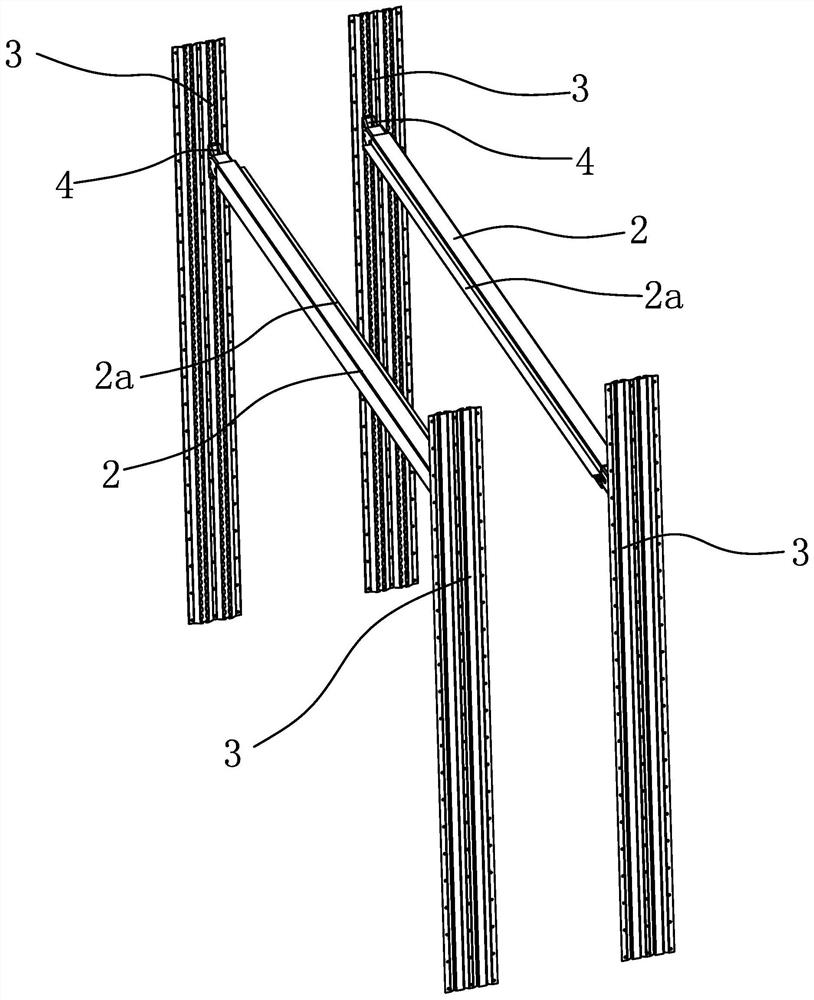

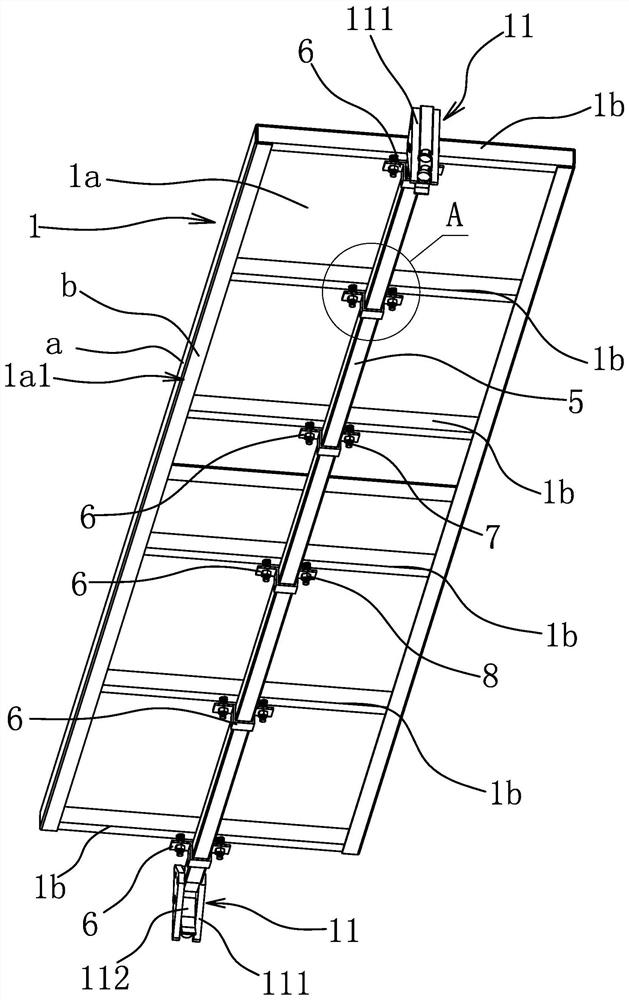

[0045] Such as figure 1 As shown, the layering device of the compartment includes a support plate 1, four main vertical rails 3, two auxiliary vertical rails 10, two support beams 2 parallel to each other and arranged at intervals, the support plate 1 is in the shape of a rectangular plate, Wherein two main vertical rails 3 and an auxiliary vertical rail 10 are fixed on the left inner wall of the compartment, and the other two main vertical rails 3 and the auxiliary vertical rail 10 are fixed on the right inner wall of the compartment, and four The two main vertical rails 3 are opposite to each other, and the two auxiliary vertical rails 10 are opposite to each other and opposite to the two ends of the support plate 1 respectively. The two ends of the support plate 1 are at a certain distance from the adjacent auxiliary vertical rail 10, so that a certain space is reserved between the two ends of the support plate 1 and the inner wall of the carriage. Hold the end of the supp...

Embodiment 2

[0056] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 13 As shown, the bottom surfaces of the two long sides of the support plate 1 rest on the top surfaces of the two support beams 2 respectively, and there are protrusions on the top surfaces of the support beams 2 that abut against the side walls of the two long sides of the support plate 1. 2b.

Embodiment 3

[0058] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 14 As shown, the connection assembly includes two support tubes 12, and the two support tubes 12 are respectively arranged at the bottom of the two ends of the support plate 1. The support tube 12 and the reinforcing beam 1b adopt the same connection structure as that of the first embodiment, and each support tube 12 A telescopic rod 5b is slidably arranged inside, and the outer end of the telescopic rod 5b is hinged with a locking part 2 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com