Transfer-connection method and application thereof

A transfer and rotation mechanism technology, applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problem of low transfer efficiency, achieve the effects of shortening the no-load travel, improving the production cycle, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

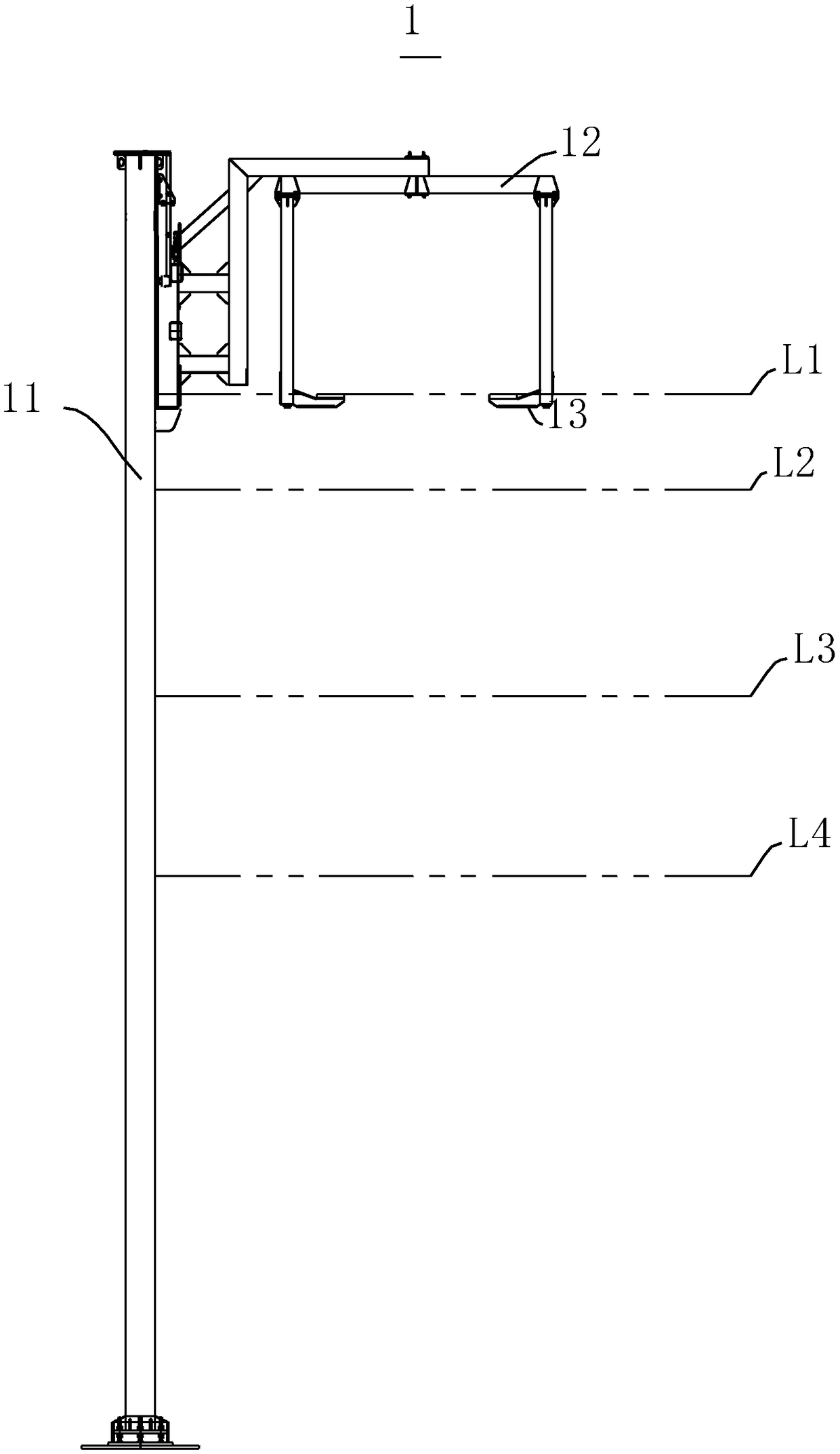

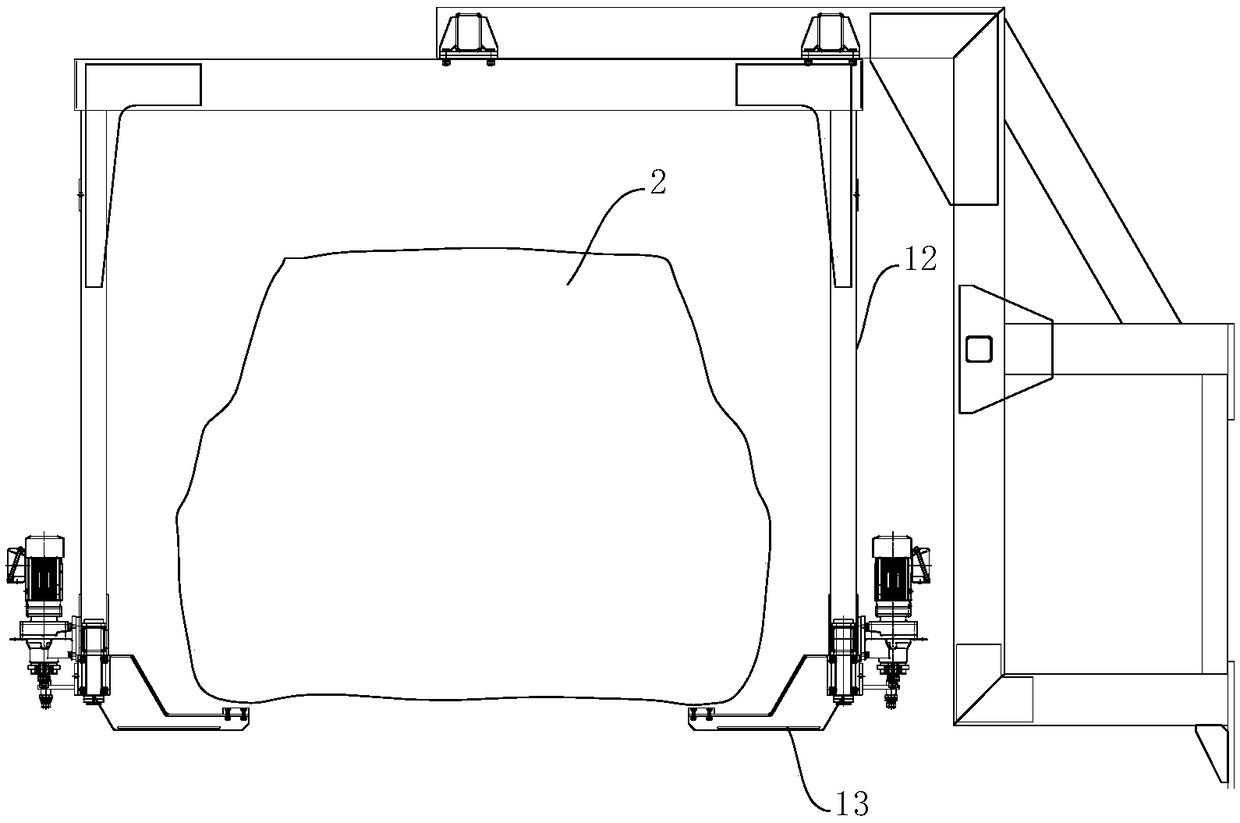

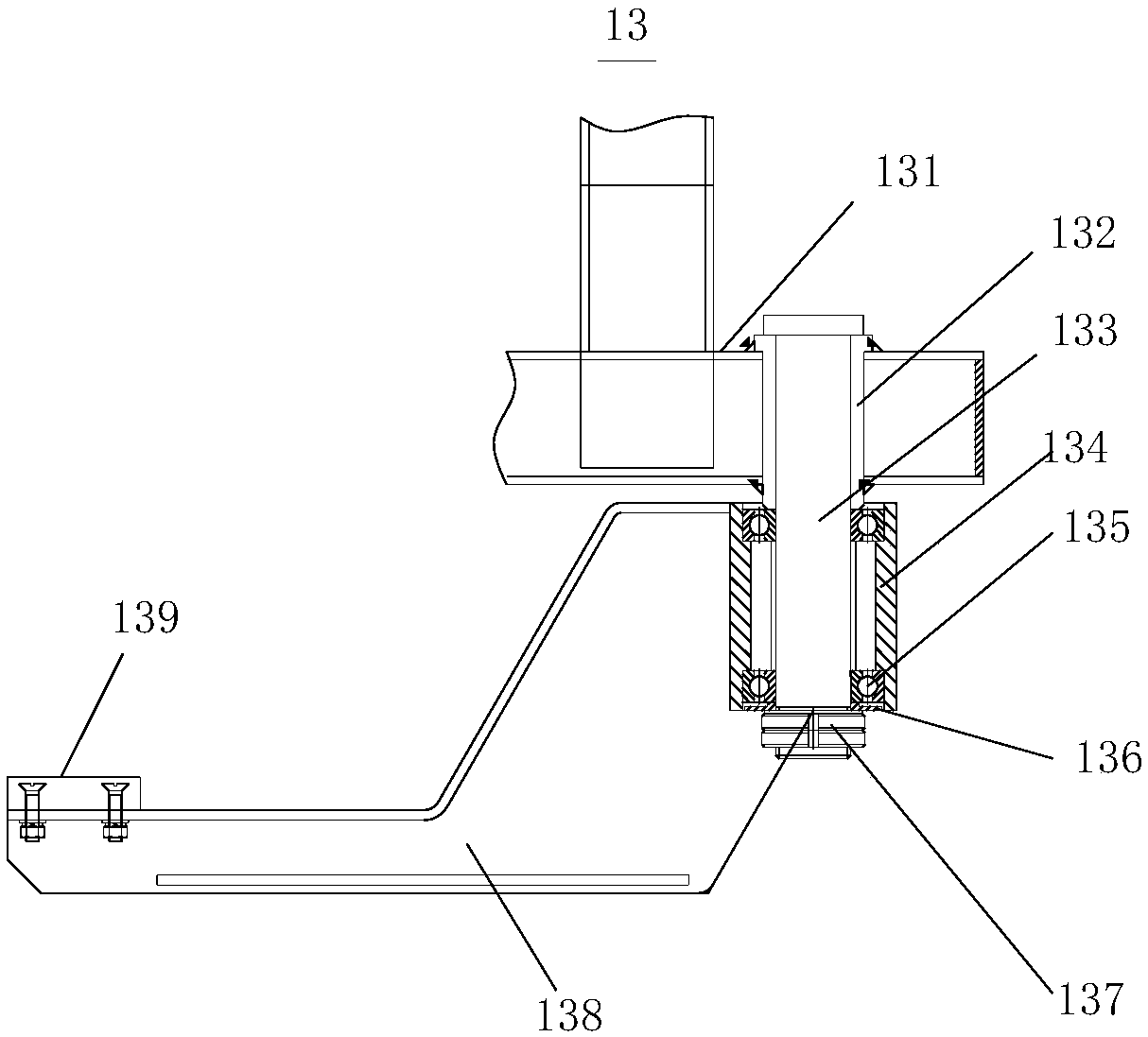

[0058] See Figure 1-Figure 11 . The invention provides a switching system and a switching method. The switching system and the switching method are used to move products from a first production line to a second production line. The switching system and switching method provided by the present invention can be used in the switching process between production lines in the production process of the product.

[0059] In this embodiment, the transfer of the automobile body-in-white from the welding and assembly production line to the assembly and adjustment production line is taken as an example for description. In production, the automotive welding production line is generally located on the upper part of the assembly line, and the two are not set up in the same line. Therefore, to transfer the body-in-white from the welding production line to the assembly line, the body-in-white must be moved up and down. And the movement or rotation on the horizontal plane.

[0060] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com