Spray mist generating device

A generation device and nozzle technology, which is applied in packaging, bottling machines, transportation and packaging, etc., can solve the problems of excessive condensed water in the atomization container device, untimely flow supply, high cost, etc., and achieve strong and efficient sterilization and disinfection capabilities, Reduced equipment cost and reduced production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples.

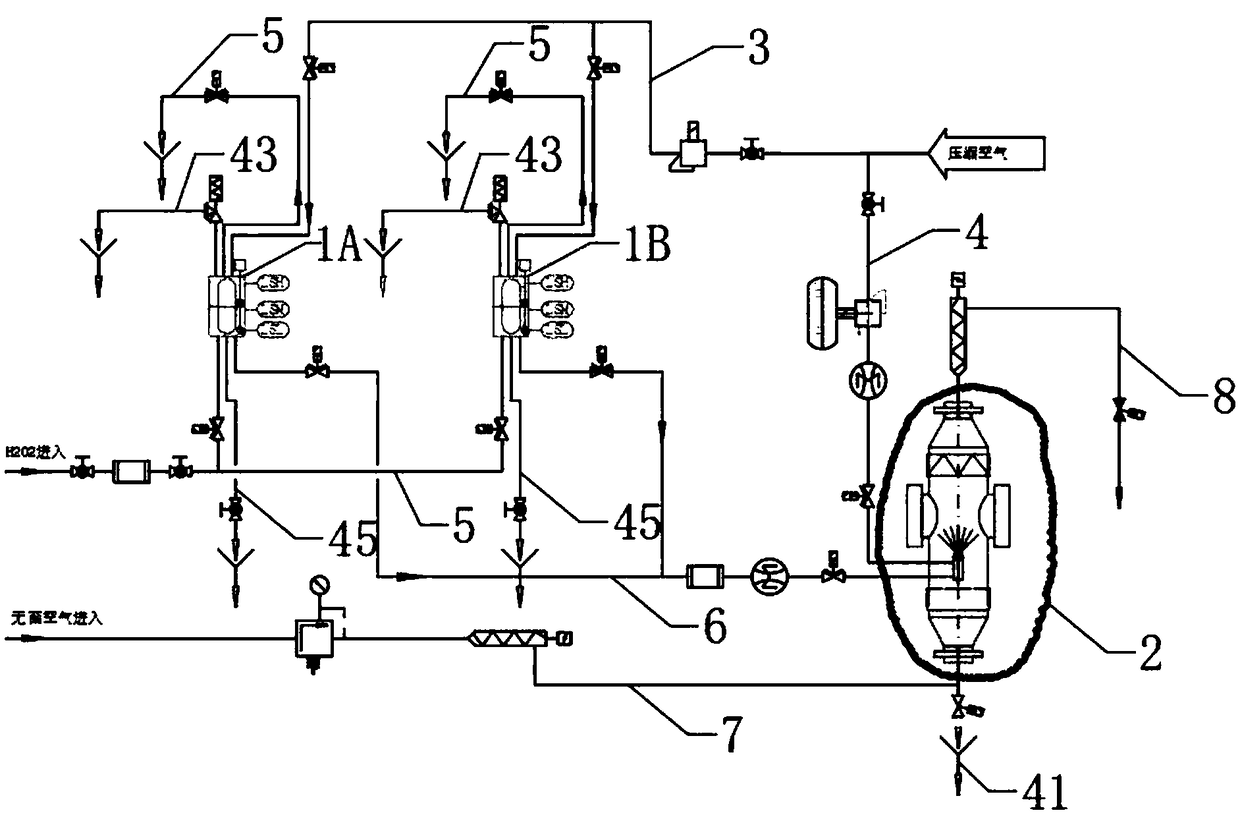

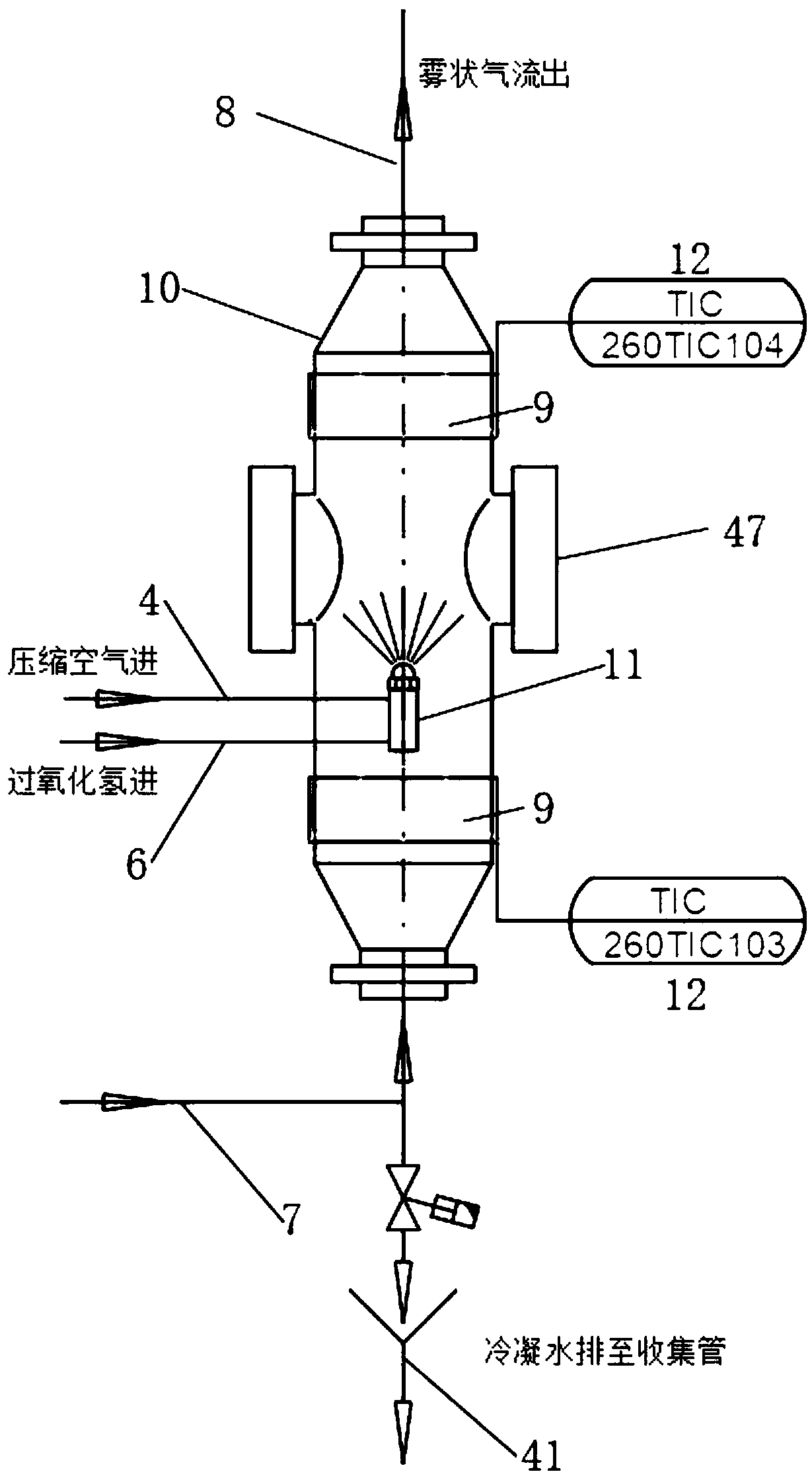

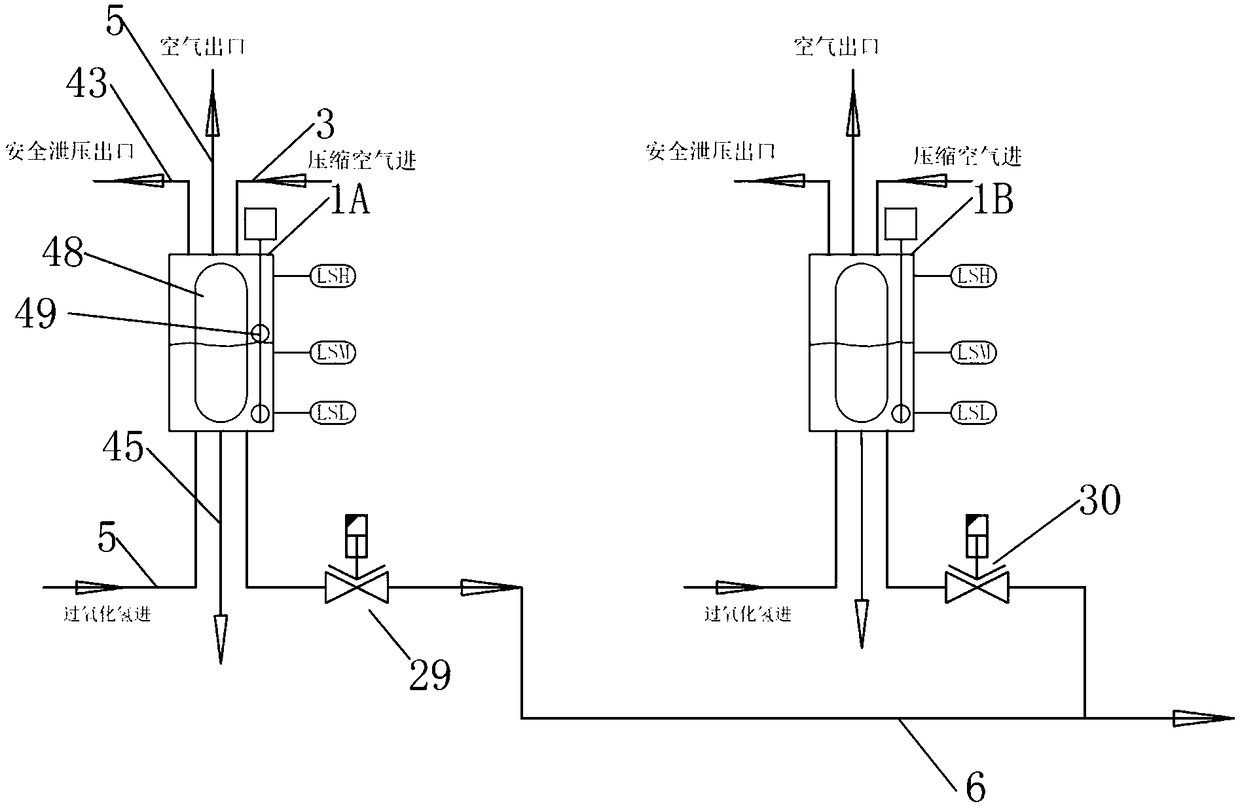

[0035] Such as figure 1 , figure 2 , image 3 As shown, a spray generating device includes hydrogen peroxide buffer container device 1A, 1B, atomization container device 2 and is used to connect hydrogen peroxide buffer container device 1A, 1B, atomization container device 2 and control device opening or closing The pipeline system; it is characterized in that at least two hydrogen peroxide buffer container devices 1A, 1B are provided; the pipeline system includes the pipeline 3 between the compressed air whose medium is compressed air in the pipeline and the hydrogen peroxide buffer container device And the pipeline 4 between the compressed air and the atomizing container device, the hydrogen peroxide in which the medium in the pipeline is hydrogen peroxide, and the pipeline 5 between the hydrogen peroxide buffer container device from the outside and the hydrogen peroxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com