Decoration firing stove for glasses

A technology for glass cups and roasting flowers, which is applied to furnaces, stove types, lighting and heating equipment, etc., can solve problems such as uneven heating of glass cups and poor roasting effect, and achieve improved roasting effect, lifting effect, and heating uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

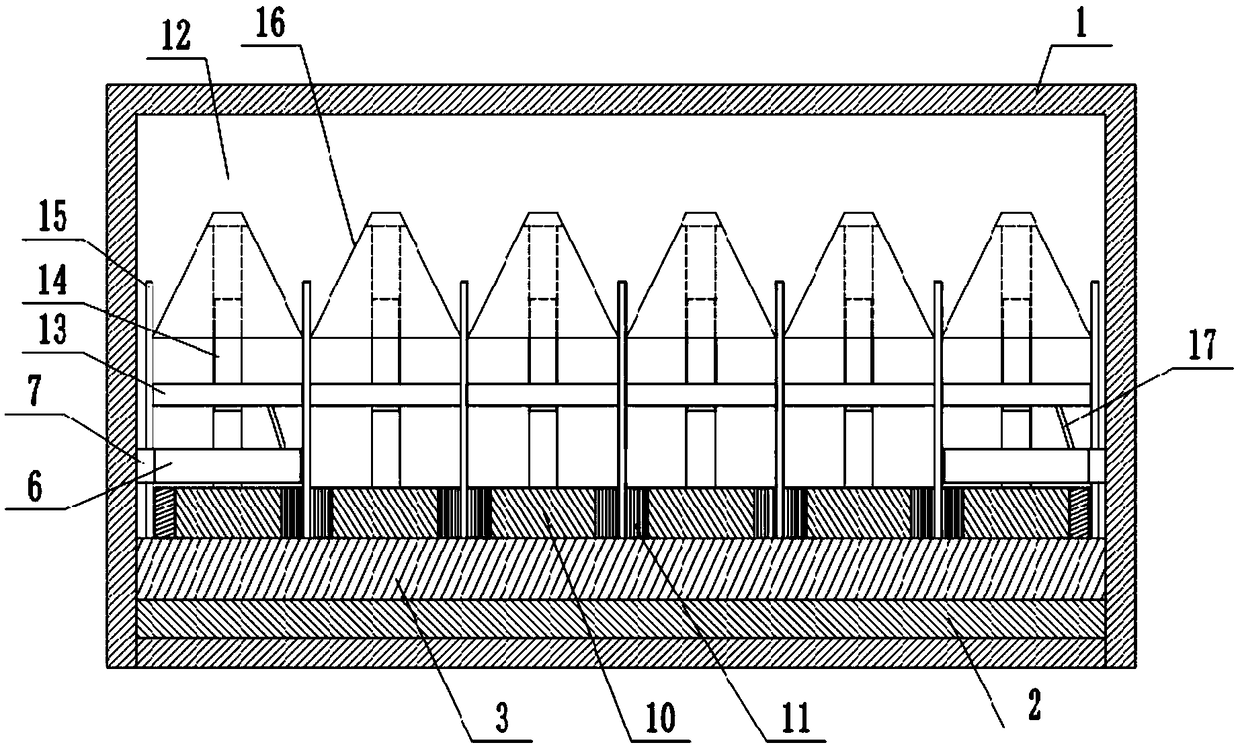

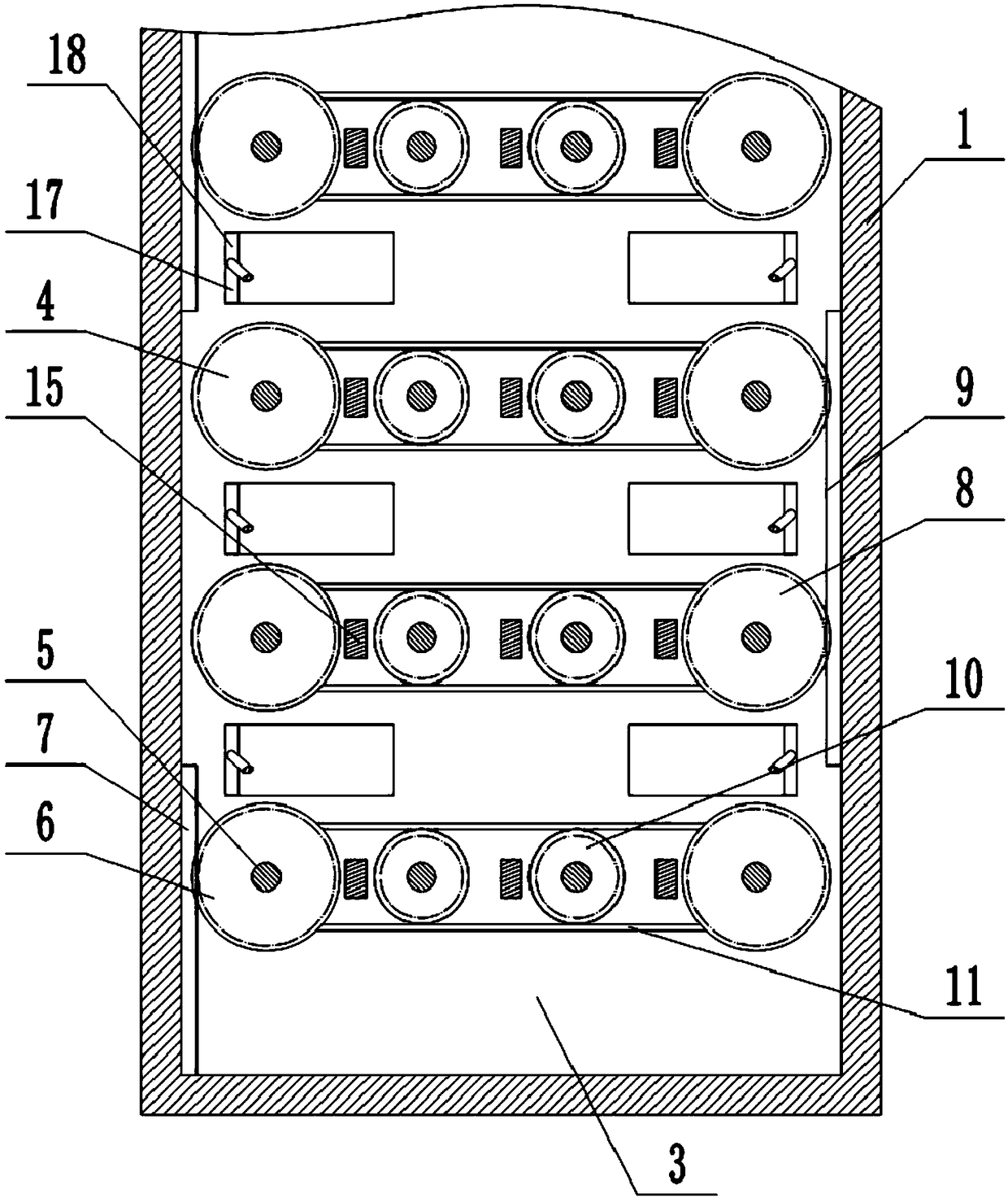

[0023] The reference signs in the drawings of the description include: furnace body 1, conveyor belt 2, placement plate 3, placement unit 4, rotating shaft 5, first gear 6, first tooth portion 7, second gear 8, second tooth portion 9, Sprocket 10, chain 11, top block 12, top plate 13, threaded portion 14, guide plate 15, glass cup 16, connecting rod 17, riser 18.

[0024] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0025] The glass decoration furnace is mainly composed of a furnace body 1, a conveyor belt 2, a placing plate 3, and several placing units 4. The conveyor belt 2 is passed through the furnace body 1, and the placing plate 3 is fixed on the conveyor belt 2 through splints.

[0026] Several placing units 4 are evenly distributed on the placing plate 3 along the conveying direction of the conveyor belt 2, and the placing units 4 are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com