Ammoniacal-odor-free foaming agent masterbatch special for low-density polyethylene (LDPE) high foaming process, and preparation method of ammoniacal-odor-free foaming agent masterbatch

A foaming agent and high-foaming technology, which is applied in the field of ammonia-free foaming agent masterbatch and its preparation for LDPE high-foaming process, which can solve the problem of stimulating ammonia smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

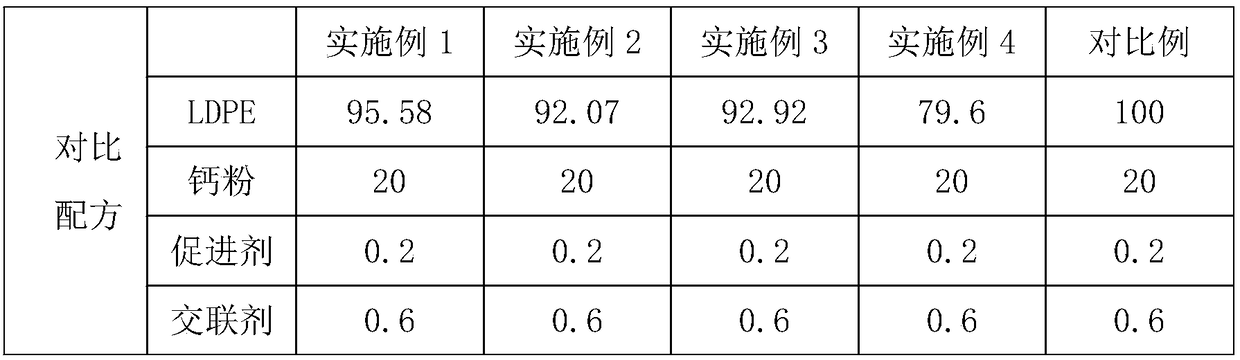

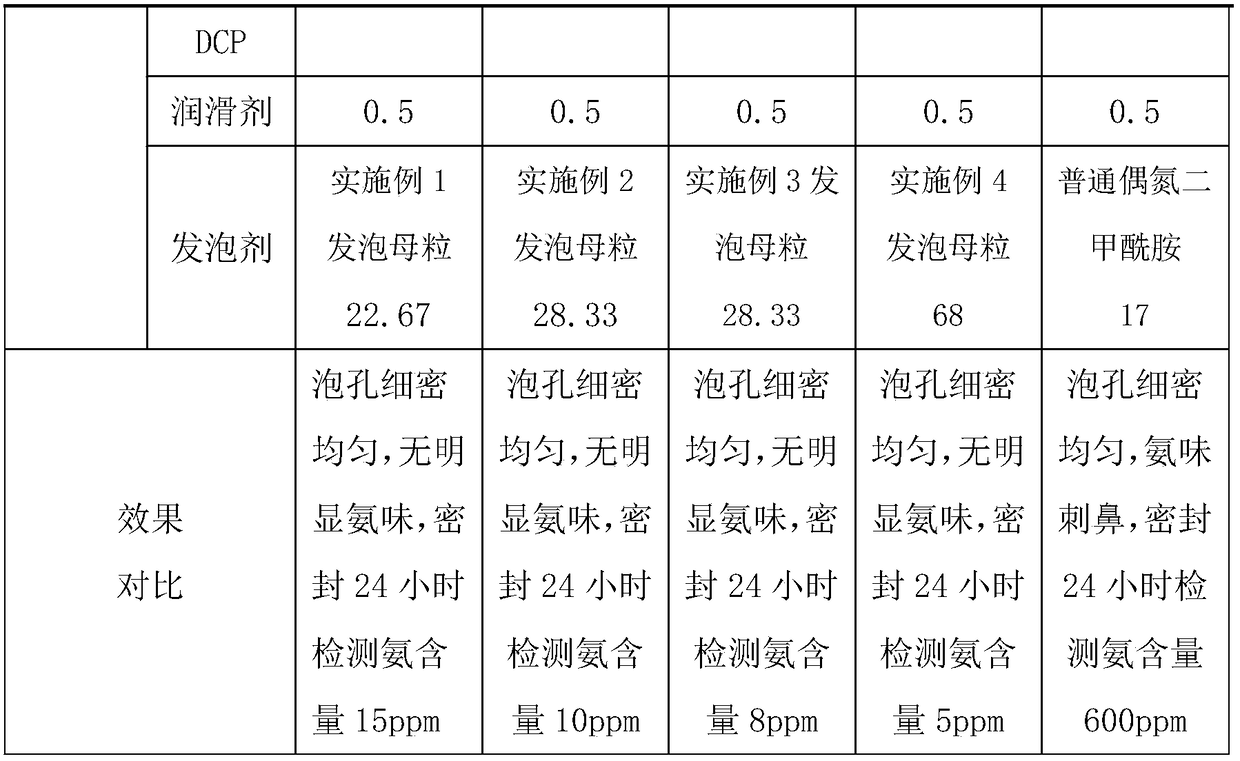

Embodiment 1

[0019] A non-ammonia-smell foaming agent master batch for LDPE high foaming, which is composed of 75 parts of azodicarbonamide, 5 parts of ammonia removal agent, 0.5 part of dispersant and 19.5 parts of carrier resin in parts by weight. Wherein the ammonia removal agent is citric acid, which is used to remove the by-product ammonia and eliminate the pungent smell in the foamed product. The dispersant is white oil, which is used to help and improve the uniform dispersion effect of the effective components of azodicarbonamide and ammonia removal agent in the carrier resin. The carrier resin is ethylene-vinyl acetate, which is used to pre-mix azodicarbonamide and ammonia removal agent to form a high concentration and easy dispersion.

[0020] The preparation method is: add the proportioned azodicarbonamide, citric acid, white oil, and ethylene-vinyl acetate resin into the internal mixer, and make the internal mixing The temperature of the material in the machine reaches 90°C, an...

Embodiment 2

[0025] A non-ammonia-smell foaming agent master batch for LDPE high foaming, which is composed of 60 parts of azodicarbonamide, 10 parts of ammonia removal agent, 2 parts of dispersant and 28 parts of carrier resin in parts by weight. Among them, the ammonia removal agent is calcium chloride, which is used to remove the by-product ammonia and eliminate the pungent smell in the foamed product. The dispersant is stearic acid, which is used to help and improve the uniform dispersion effect of the effective components of the azodicarbonamide and the ammonia removal agent in the carrier resin. The carrier resin is ethylene-vinyl acetate, which is used to pre-mix azodicarbonamide and ammonia removal agent to form a high concentration and easy dispersion.

[0026] The preparation method is: add the proportioned azodicarbonamide, calcium chloride, stearic acid, and ethylene-vinyl acetate resin into the internal mixer, so that the temperature of the material in the internal mixer reach...

Embodiment 3

[0029] A non-ammonia-smell foaming agent master batch for LDPE high foaming, which is composed of 60 parts of azodicarbonamide, 10 parts of ammonia removal agent, 5 parts of dispersant and 25 parts of carrier resin in parts by weight. Among them, the ammonia removal agent is aluminum tripolyphosphate, which is used to remove the by-product ammonia and eliminate the pungent smell in the foamed product. The dispersant is polyethylene wax (PE wax), which is used to help and improve the uniform dispersion effect of the effective components of azodicarbonamide and ammonia removal agent on the carrier resin. The carrier resin is polyolefin elastomer, which is used to pre-mix azodicarbonamide and ammonia removal agent to form a high concentration and easy dispersion.

[0030] The preparation method is: add the proportioned azodicarbonamide, aluminum tripolyphosphate, PE wax, and polyolefin elastomer into the internal mixer, so that the temperature of the material in the internal mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com