Magnetron sputtering vacuum coating equipment for uniformly distributing process gas

A technology of vacuum coating and magnetron sputtering, applied in sputtering coating, vacuum evaporation coating, metal material coating process, etc., can solve problems such as uneven gas distribution, and achieve the effect of avoiding disturbance and uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

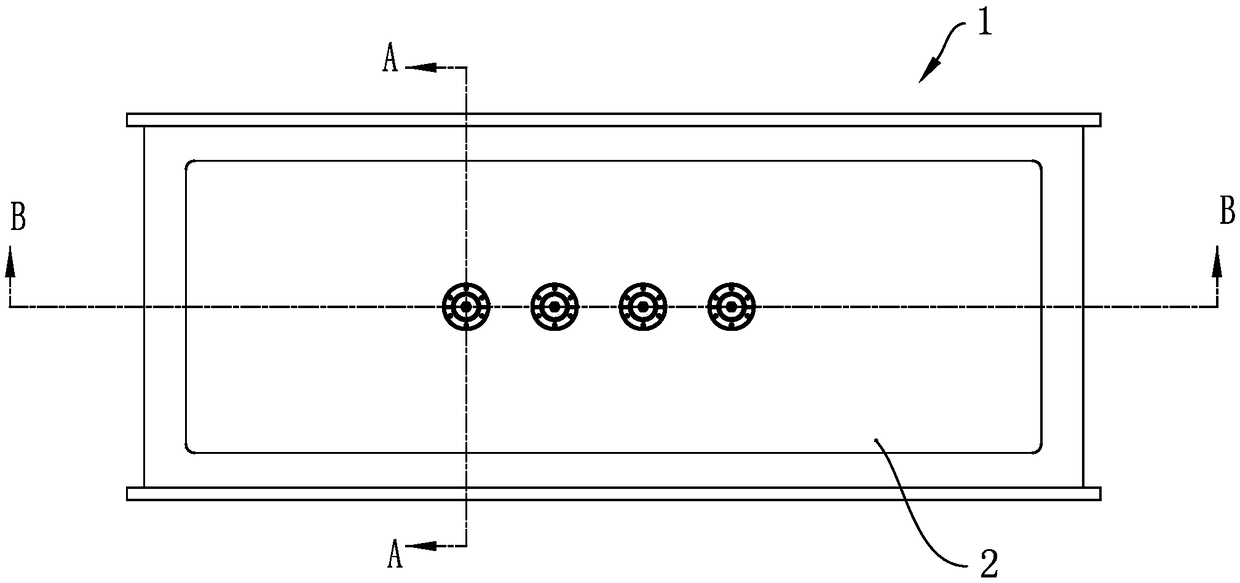

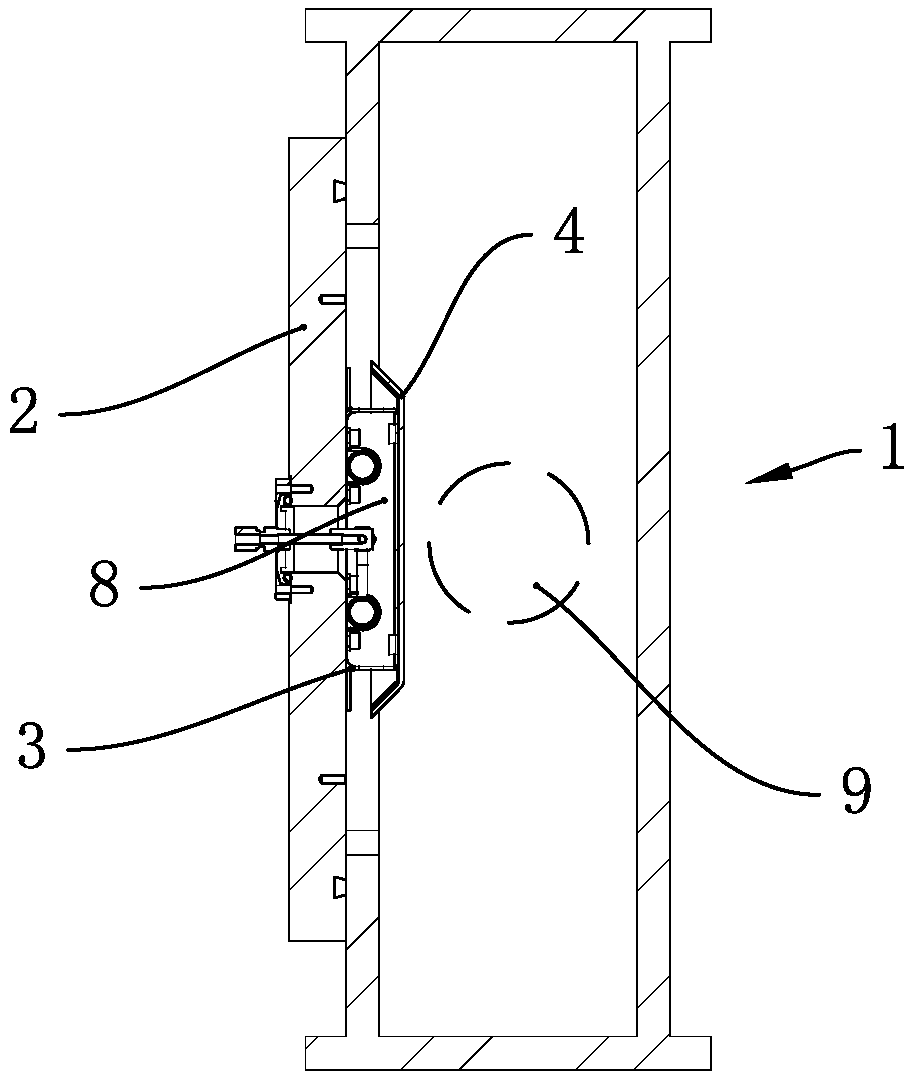

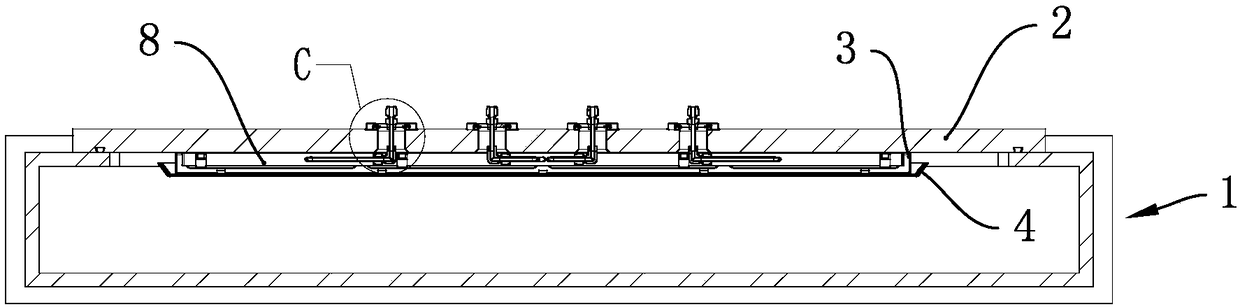

[0023] Such as Figure 1-3 As shown, a magnetron sputtering vacuum coating equipment includes a vacuum chamber 1, the intake side of the vacuum chamber 1 has an opening and a door panel 2 that closes the opening, the inside of the door panel 2 is provided with a concave mixing baffle 3, the mixing baffle The edge of the board 3 has a folded edge, and the folded edge is fixed on the door panel 2, and the mixing baffle 3 extends into the interior of the vacuum chamber 1 as a whole, and an air outlet 31 is arranged on the folded edge in the length direction. The outside of the mixing baffle 3 is also provided with an anti-collision baffle 4 for protecting the mixing baffle and preventing materials from being deposited on the mixing baffle 3 .

[0024] The main purpose of adopting the above-mentioned structure is to facilitate assembly. If this factor is not considered, other side openings of the vacuum chamber can also be opened, but after the vacuum chamber is finalized, it is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com