Bamboo and wood floor splicing structure

A floor, bamboo and wood technology, applied in the field of bamboo and wood floor splicing structure, can solve the problems of easy loosening or erosion, unreliable degree of insertion and sealing effect of mortise and tenon structure, etc., achieves simple structure, guarantees firmness and sealing The effect of convenient operation and plug-in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

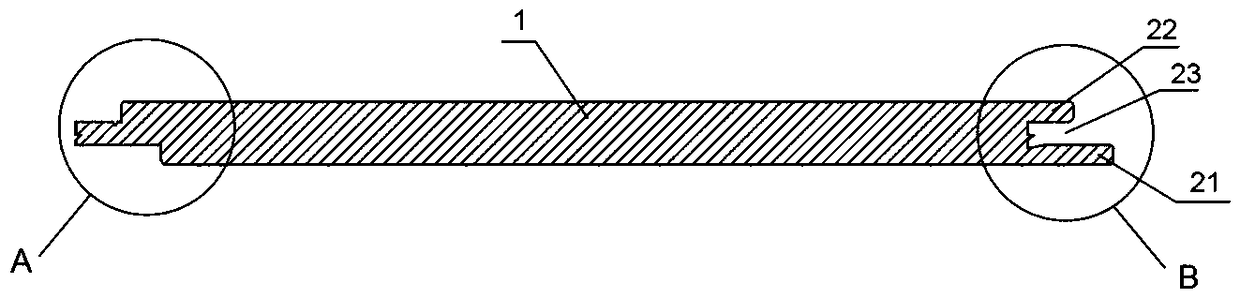

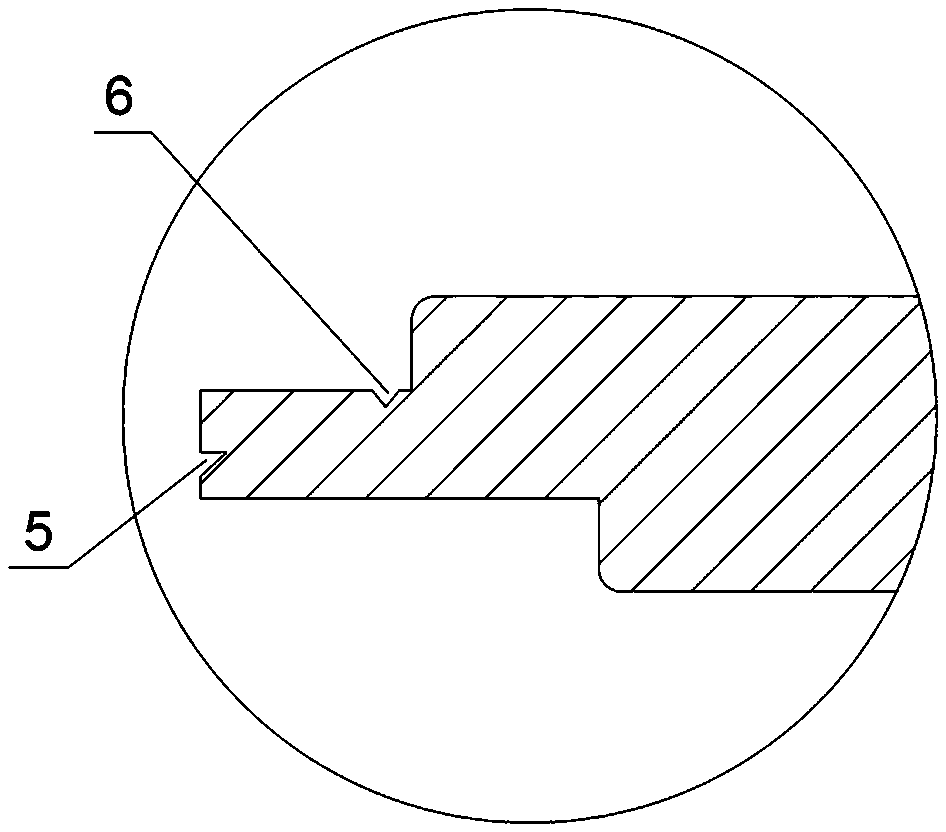

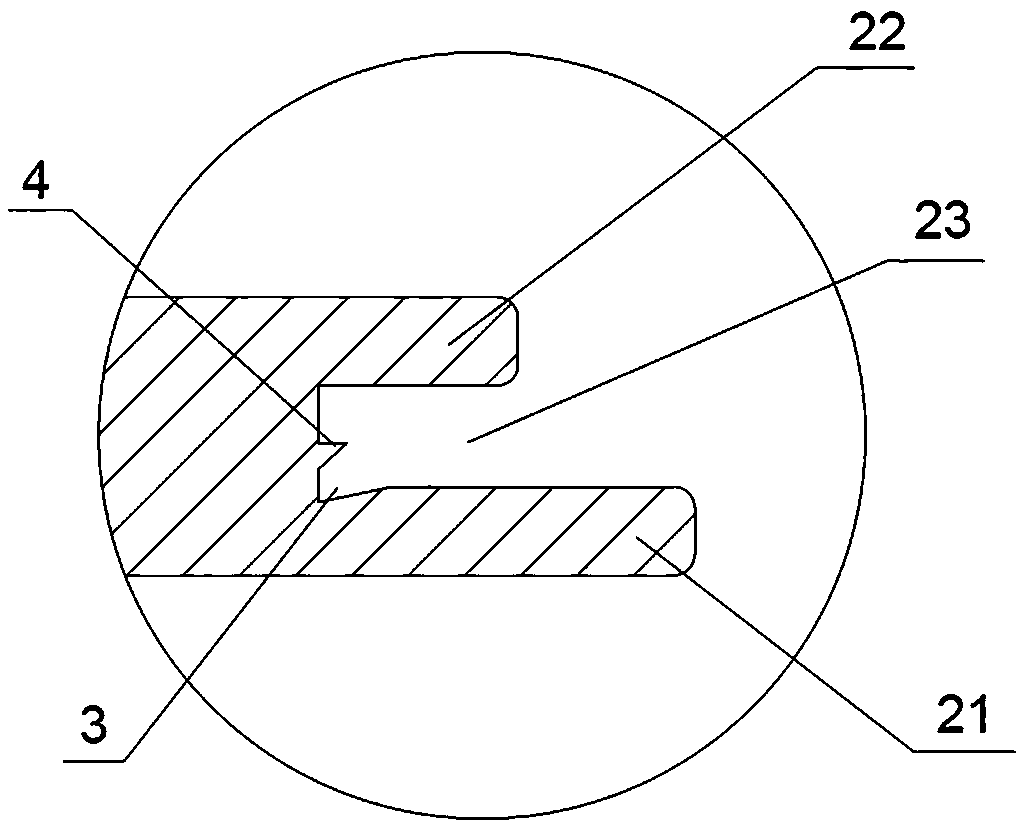

[0020] A bamboo-wood floor splicing structure, comprising a plurality of sequentially spliced unit boards, the unit boards include a main body 1 and tenon joints and mortise joints respectively arranged at both ends of the main body 1, the mortise joints include The lower side plate 21, the upper side plate 22 and the slot 23 in the middle, the lower side plate 21 is provided with an expansion chamber 3 near one end of the main body 1 and towards the side of the upper side plate 22, the slot 23. An expansion strip 4 is provided at the bottom, and an expansion groove 5 matching the expansion strip 4 is provided at the end of the tenon joint; a sealing groove 6 is provided on the upper side of the tenon joint close to the main body 1 .

[0021] Principle of action: When the mortise joint and the mortise joint are inserted, the expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com