Building elevator shaft mouth safety protection platform

A safety protection and elevator technology, which is applied in the directions of construction, building structure, housing structure support, etc., can solve the problem of increasing rental costs, labor costs and time investment, the lack of comprehensive protection against falling objects and injury, and the safety of high-altitude effects. If there is no guarantee and other problems, it can save the time of demoulding, reduce the cost and extra expenses, and reduce the rental cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings. The positional relationship described in the drawings is for illustrative purposes only, and should not be construed as a limitation on this patent.

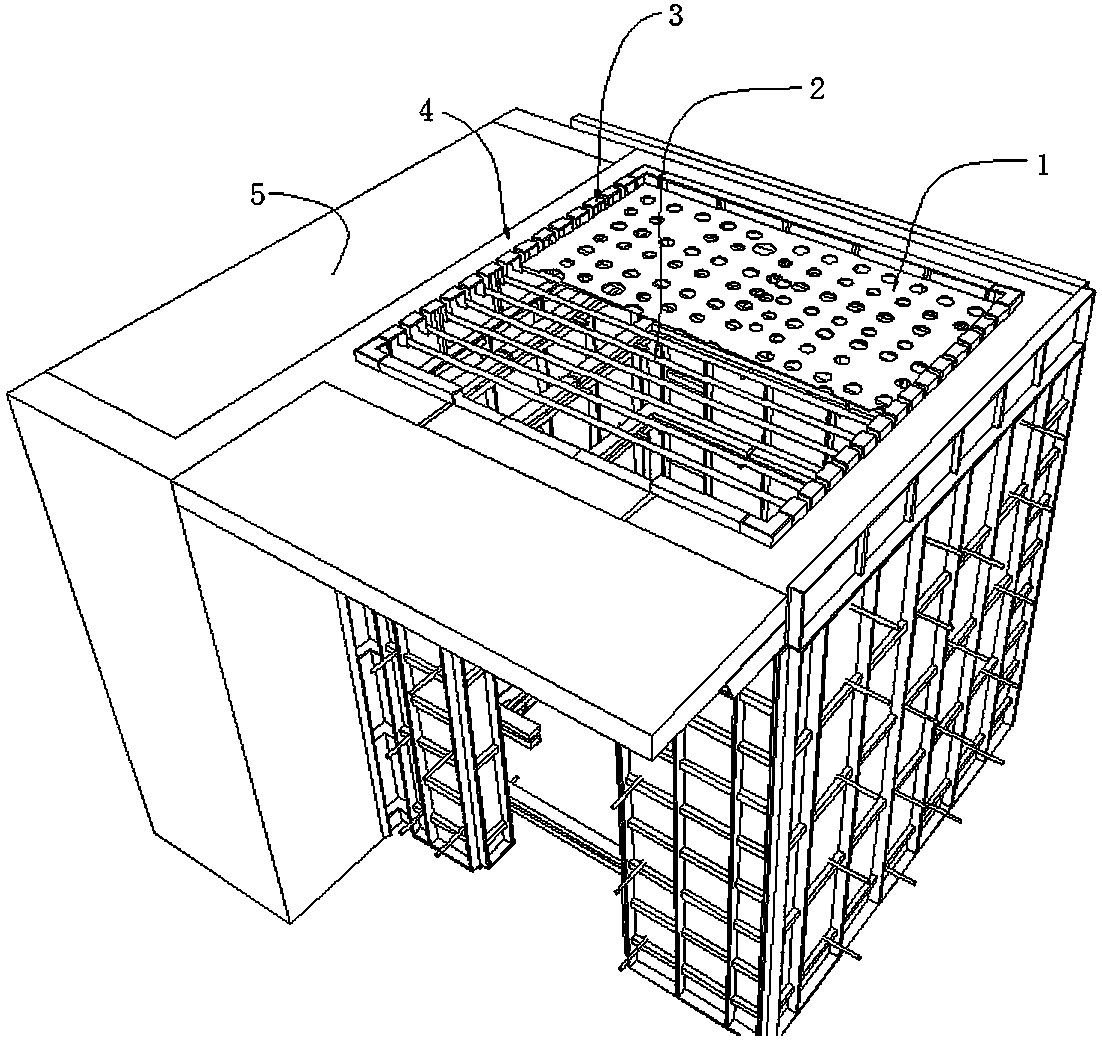

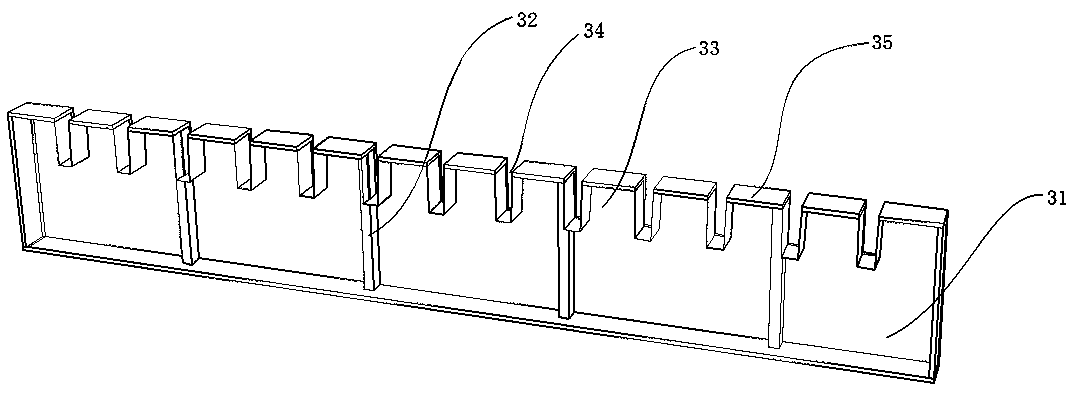

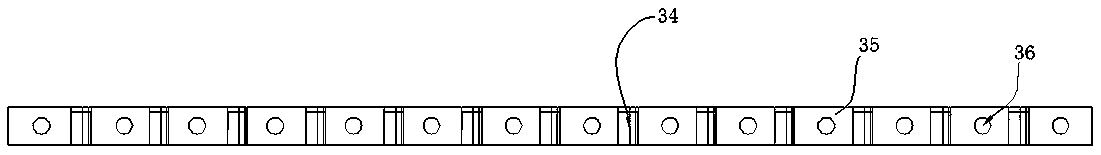

[0021] Such as Figure 1-4 As shown, a building elevator wellhead safety protection platform includes a lateral fixing plate 3, a support bar 2 and a cover plate 1, wherein the side edge of the lateral fixing plate 3 is a concave-convex horse tooth rubbing structure, and the horse teeth The tooth rubbing structure is composed of a plurality of protruding blocks 33 arranged equidistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com