Novel fan metal supporting plate and manufacturing equipment

A technology for manufacturing equipment and fans, applied in the field of new fan metal support plates and manufacturing equipment, can solve problems affecting the quality and use effect of fan metal support plates, and achieve the effects of facilitating promotion and utilization, reducing impact force, and reducing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

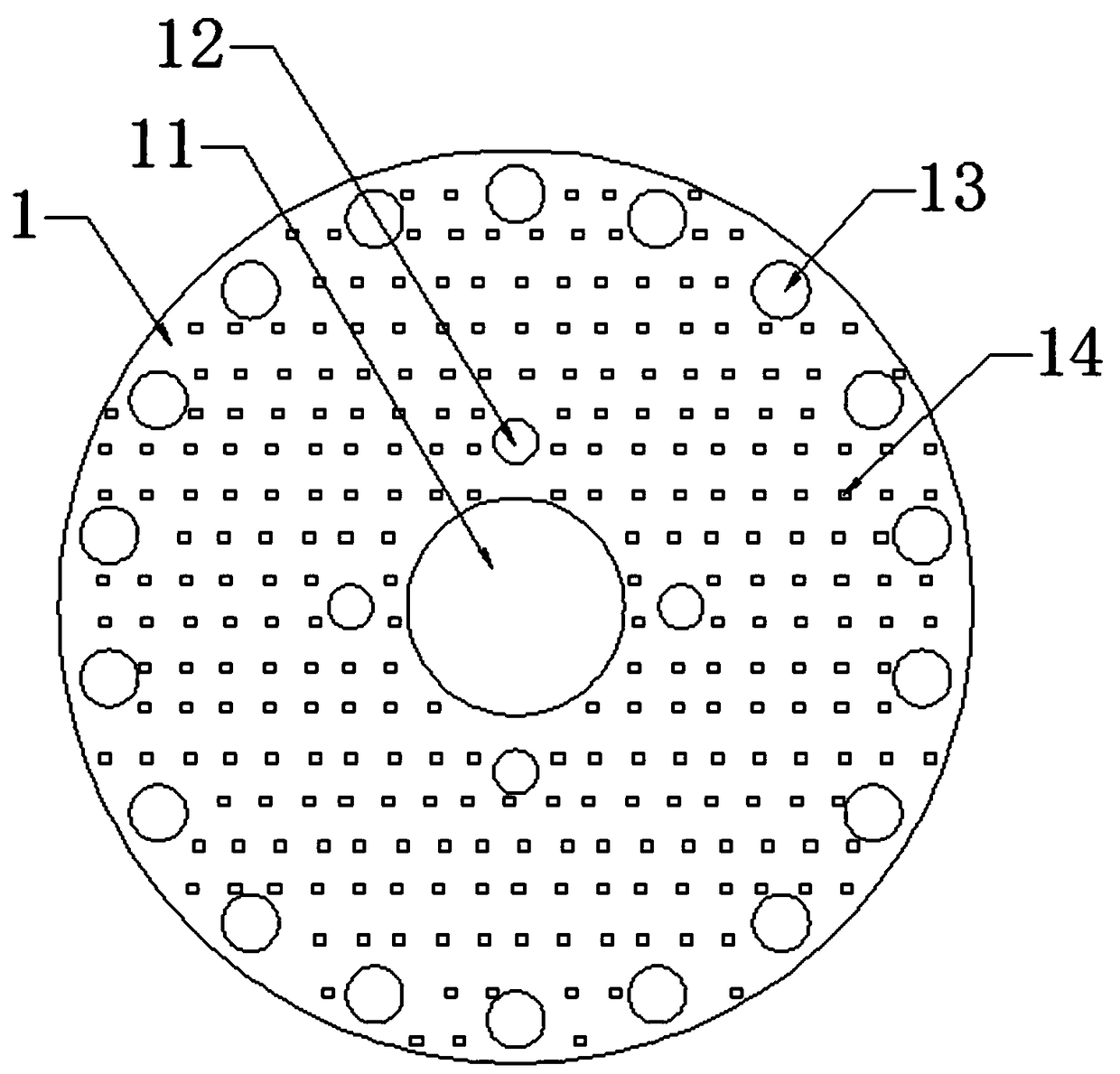

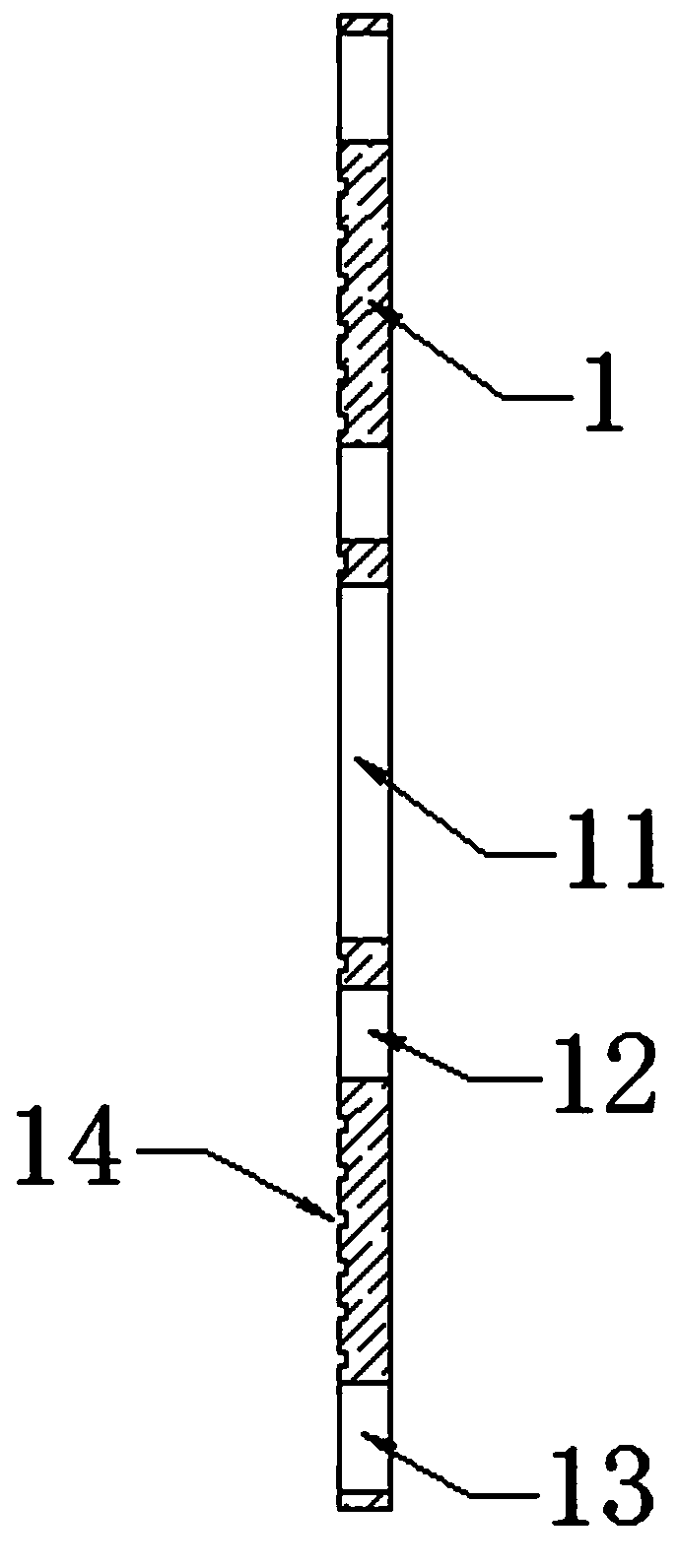

[0033] Example 1, Figure 1~2 The novel fan metal support plate of the present invention is shown, including:

[0034] Body 1, a center positioning hole 11 is provided at the center of the body 1, and a plurality of installation holes 12 surrounding the center positioning hole 11 are provided in the body 1; a plurality of side holes 13 are provided on the edge ring of the body 1;

[0035] It also includes several relief grooves 14 arranged and distributed on the surface of the body 1 .

[0036] In this technical solution, the fan metal support plate is fixedly installed between the engine fan and the mounting bracket through the center positioning hole 11, the installation hole 12 and the side hole 13 of the body 1, and the stress relief grooves 14 distributed on the surface of the body 1 relieve stress. The metal supporting plate of the fan further reduces the vibration and jump of the fan, which is beneficial to improving the quality of the fan and is convenient for popular...

Embodiment 2

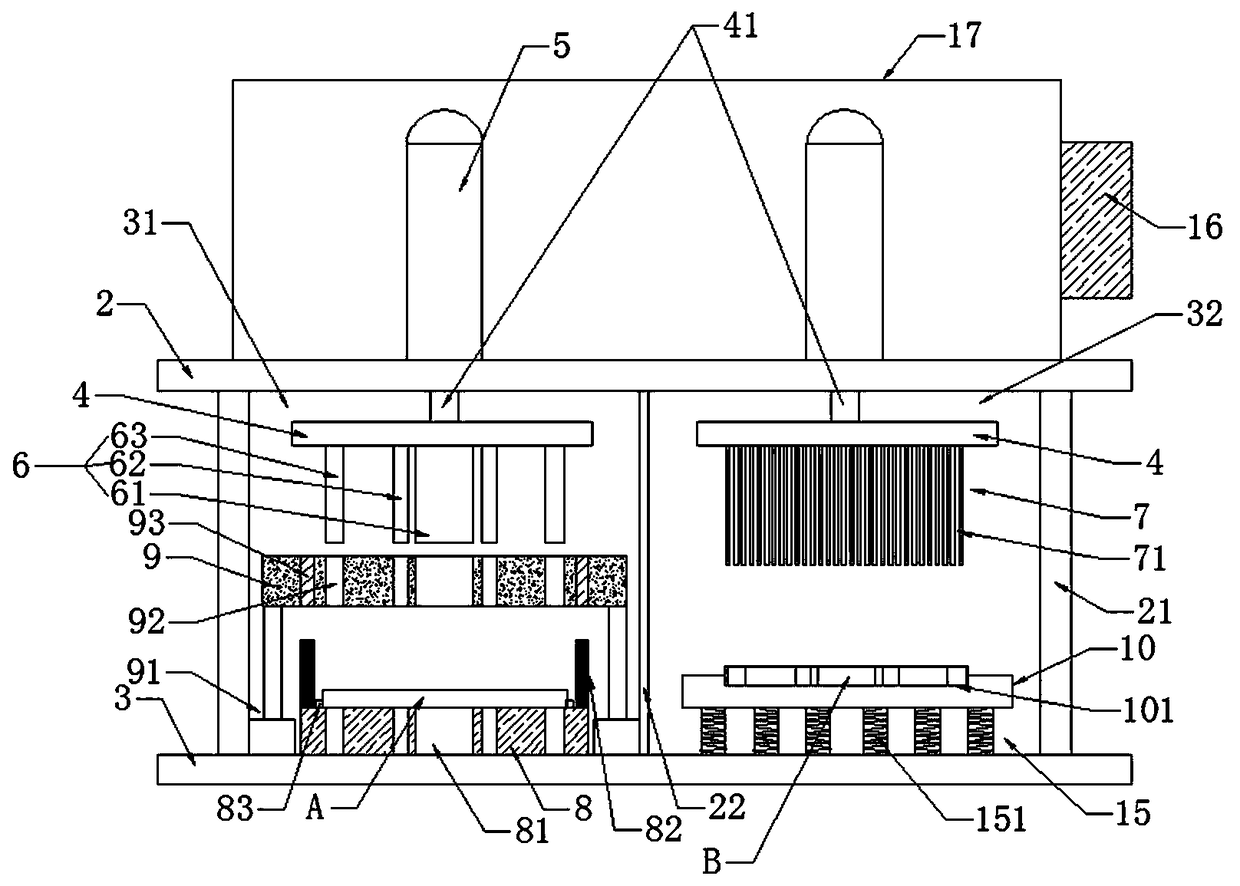

[0037] Example 2, Figure 3~4 The manufacturing equipment of novel fan metal supporting plate of the present invention is shown, including:

[0038] The top plate 2 and the bottom plate 3 that are arranged symmetrically through the connection of several fixed columns 21, the space between the top plate 2 and the bottom plate 3 are separated by a partition plate 22 to form a punching area 31 and a reaction area 32; Each area 32 is provided with an upper extrusion plate 4, and the top of the upper extrusion plate 4 is installed below the stamping cylinder 5 through a stamping shaft 41. The stamping shaft 41 vertically penetrates the top plate 2 and is vertically welded on the upper extrusion plate 4; A punch assembly 6 is installed at the bottom of the upper extrusion plate 4 of the punching area 31, and an anti-stress steel nail assembly 7 is installed at the bottom of the upper extrusion plate 4 of the stress relief area 32; the punch assembly 6 includes a center positioning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com