Pipe connection fitting

A technology for connecting fittings and pipes, applied in the direction of connecting components, rod connection, mechanical equipment, etc., can solve the problems of easily damaged threaded hole disassembly, ineffective connection, low disassembly efficiency, etc., and achieves easy and convenient installation process. Simple structure and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

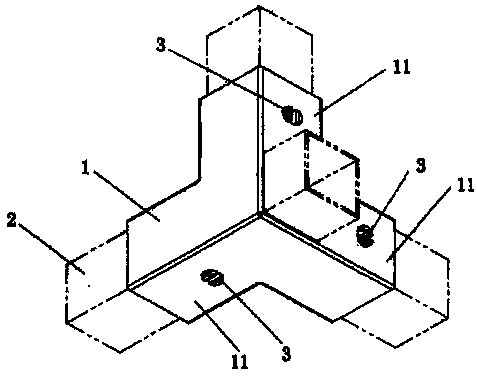

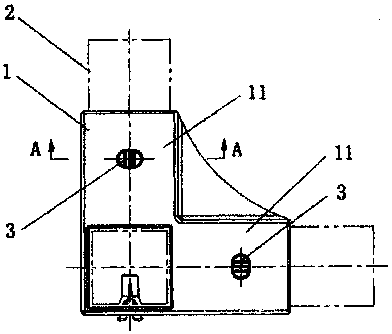

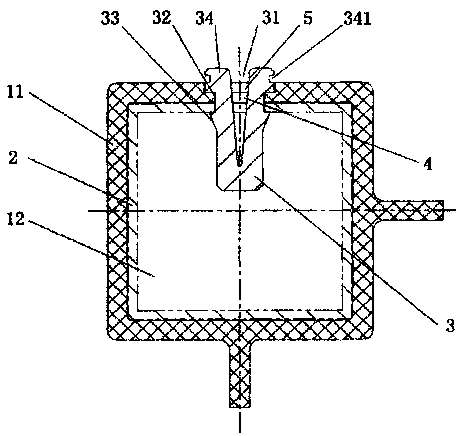

[0011] As shown in Figures 1 to 4, the pipe connection fittings include the fitting body 1 and the staple 3, the fitting body 1 is provided with a joint 11 for connecting with the pipe 2, and the joint 11 is provided with a socket 12 for accommodating the pipe 2 , the pipe 2 is inserted into the socket 12, the head of the staple 3 is provided with a pressing operation part 34, the staple 3 is provided with an elastic groove 31 extending from the pressing operation part 34 to the tail, and the middle part of the staple 3 is provided with The radial clamping groove 32, the staple 3 is inserted in the through hole 4 of the through joint 11 and the pipe material 2, the radial clamping groove 32 clamps the joint 11 and the pipe material 2 on the edge of the through hole 4, and its structure is simple and easy to disassemble When assembling, directly insert the staple 3 into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com