Buckling device used for pipe buckling joints

A technology for pipes and support plates, applied in hose connection devices, pipes/pipe joints/fittings, metal processing, etc., can solve the problems of affecting the service life of pipes, inconvenient mold replacement, and increased use costs, so as to achieve easy replacement, Good orientation and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

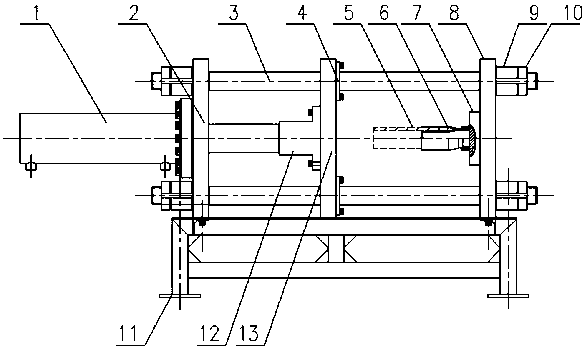

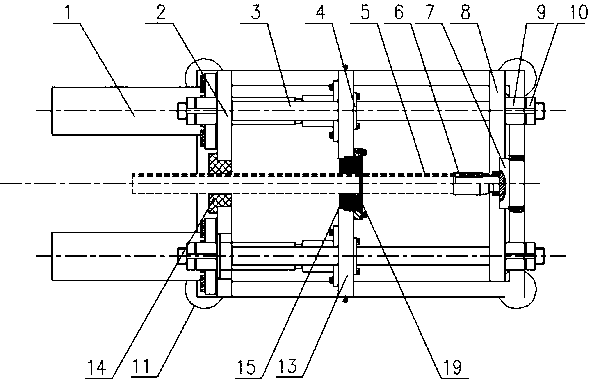

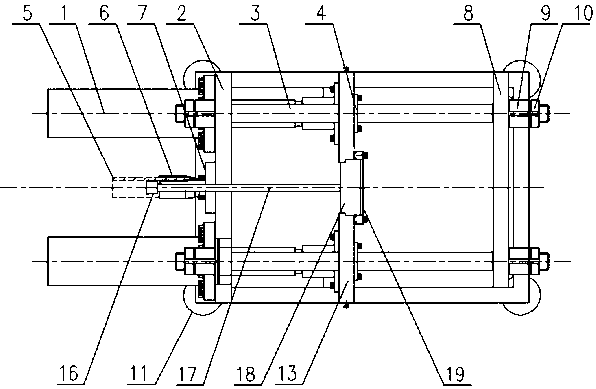

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] A crimping device for crimping pipe joints, the device is based on a frame (11), the upper end of the bracket is fixed with a front end support plate (2), a tail end support plate (8), and the front end support plate (2 ) and the tail support plate (8) are connected together by four horizontal guide posts (3), the two ends are fixed by thick round nuts (9) and thin round nuts (10), and the middle moving plate (13) is passed The sliding sleeve (4) is also installed on the horizontal guide column (3), and can slide left and right on the horizontal guide column. The tail of the two hydraulic jacks (1) is fixed on the front support plate, and the front end is equipped with a connecting seat (12) , the connecting seat (12) is fixed to the middle moving plate (13) by bolts.

[0017] Such as figure 1 , 2 As shown, when the joint is buckled, the outer buckle suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com