Cylindrical heat exchanger with high heat exchange efficiency

A technology of heat exchange efficiency and heat exchangers, applied in the direction of heat exchanger types, indirect heat exchangers, water heaters, etc., can solve the problems of shell temperature rise, achieve lower temperature rise, high heat exchange efficiency, and improve heat exchange efficiency. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

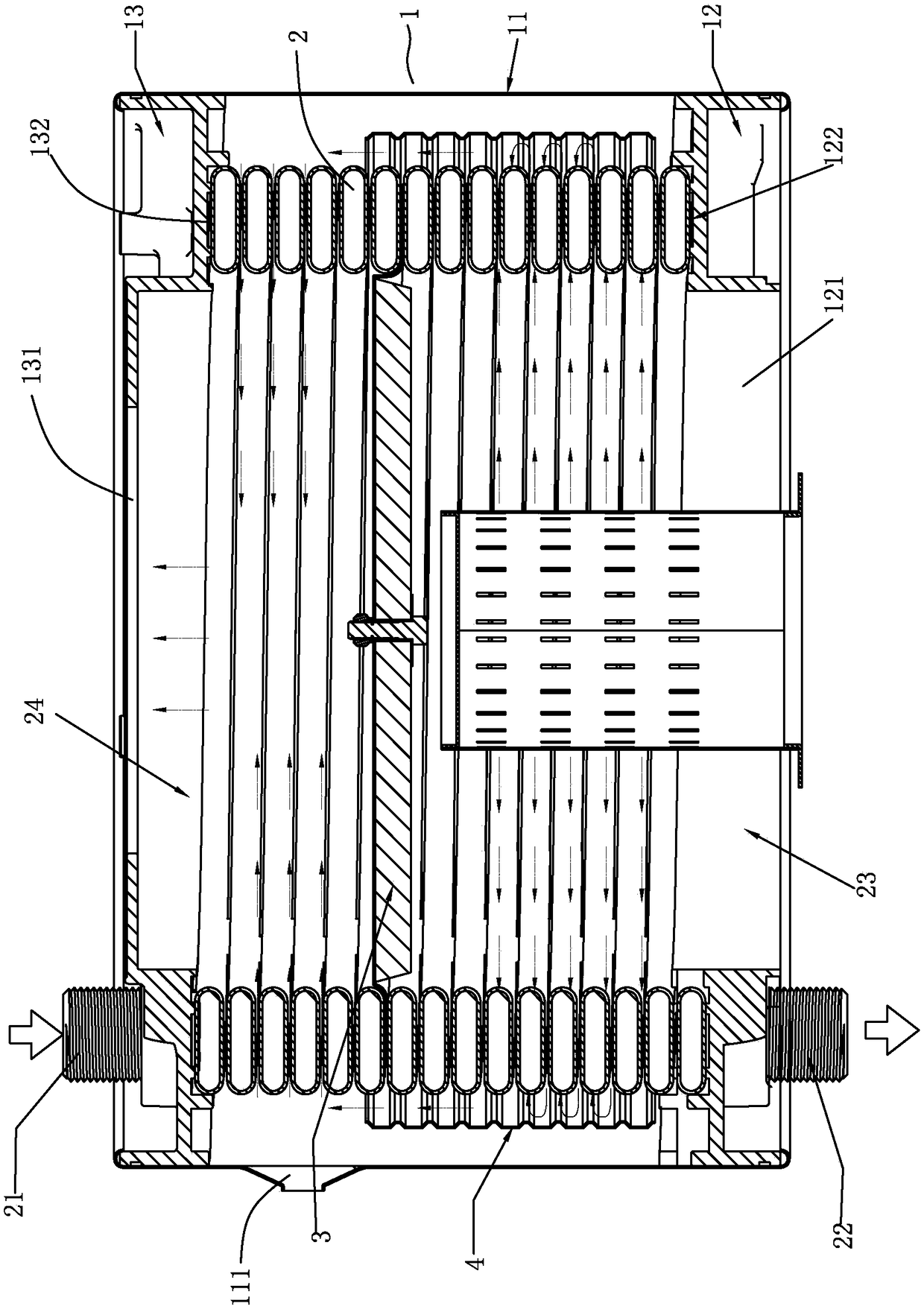

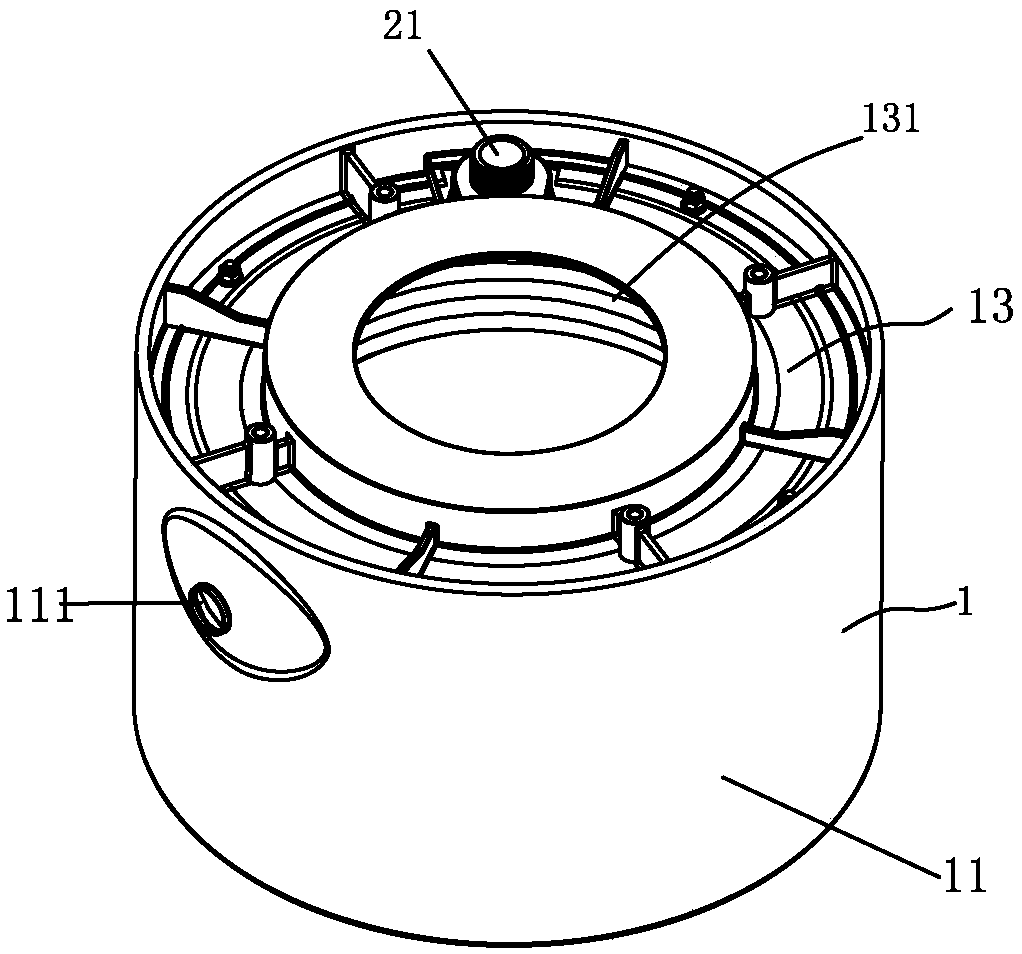

[0013] Such as figure 1 As shown, a cylindrical heat exchanger with high heat exchange efficiency includes a shell 1, a heat exchange coil 2 and a heat insulation plate 3. The shell 1 includes a circular body 11 with upper and lower openings, and a circular base. part 12 and a circular end cover part 13, the base part 12 is provided with a burner installation hole 121, a seat ring-shaped slot 122 and a water outlet port extension hole, and the end cover part 13 includes a smoke outlet hole 131 in the center, The end circular ring slot 132 surrounding the smoke outlet and the water inlet port protruding hole; the heat exchange coil 2 is made of a tube body spirally wound into a cylinder, and the water inlet end of the heat exchange coil 2 is provided with The water inlet interface 21 and the water outlet end are provided with a water outlet interface 22, and the axes o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap