A Variable Lubrication Intelligent Thrust Bearing System

A thrust bearing and variable technology, which is applied in the fields of large gearboxes, hydroelectric units, and nuclear power main pumps, can solve the problems that the bearings cannot meet the requirements of intelligent bearings and the safety factor is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

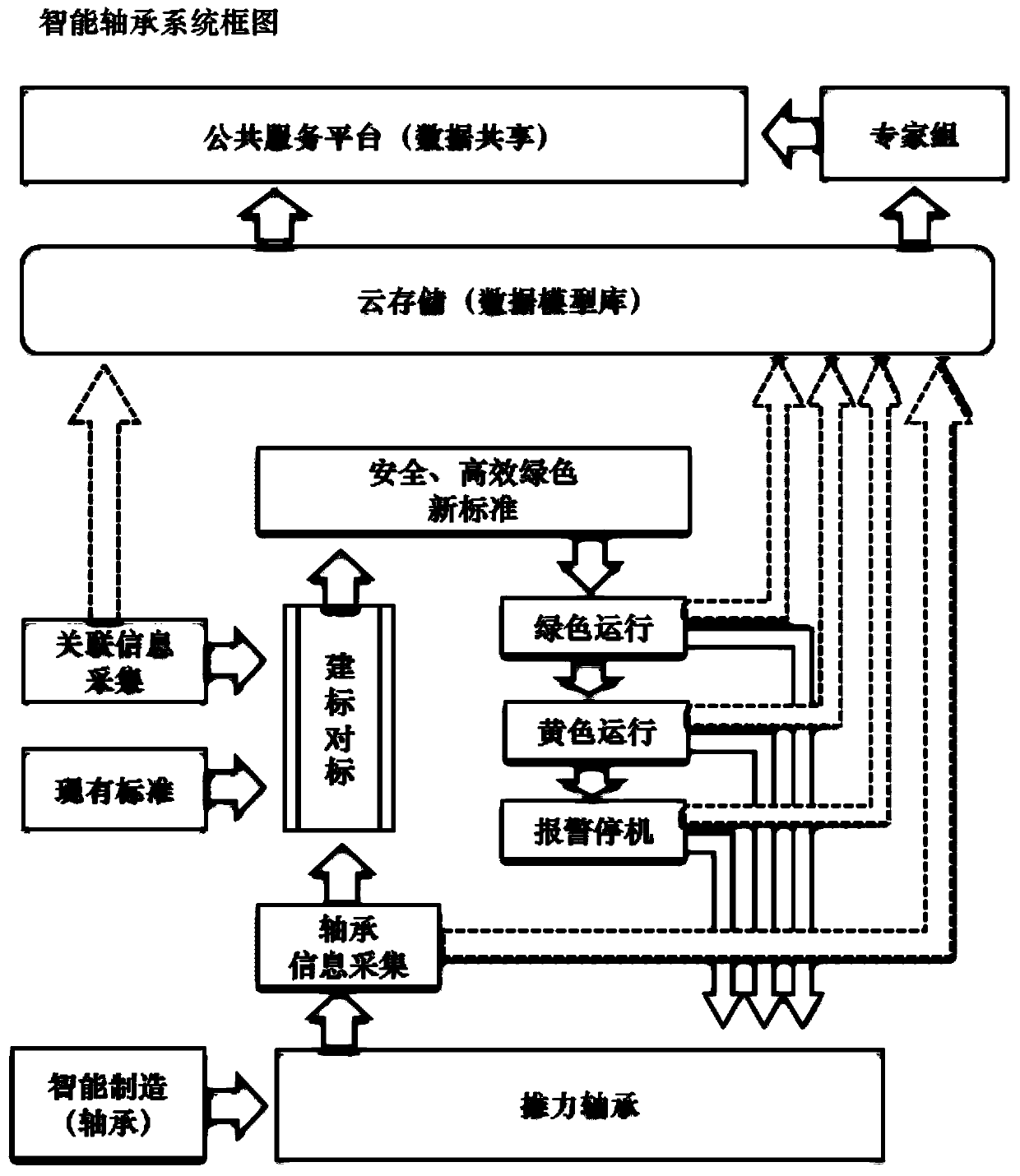

[0079] Building a standard, benchmarking

[0080] The thrust bearing testing machine simulates the operation test of the hydropower station, and verifies the establishment and benchmarking of the intelligent bearing system.

[0081]

[0082] Building standards and benchmarking diagrams

[0083] The construction standard simulates the operating conditions of a hydropower station with a speed of 600r / min, a load of 4.0MPa, an operating oil inlet temperature of 36°C, an oil film temperature of 67°C, and a water flow rate of 55m 3 / h, and it is in a stable state; increase the lubricating oil temperature to 40°C, and it is in a stable state.

[0084] For benchmarking, when the lubricating oil is in a stable state, the oil film temperature is 70°C, the oil film thickness is 0.072mm, and the water flow rate is 1.4m 3 / h.

Embodiment 2

[0086] green and yellow run

[0087] The temperature of the oil film is controlled at 70±2°C, and the related factors of the simulation change, such as adjusting the speed to increase the temperature of the oil film, and the cooling water control starts to work. The accumulative simulation is 12 hours, and the speed is adjusted every 20 minutes. The temperature of the oil film is controlled within the standard range. The temperature is basically stable, and the temperature of the oil tank is slightly lowered. As shown below:

[0088]

[0089] The yellow operation is divided into two stages. In the first stage, the oil film temperature is operated according to the standard of 70°C to 75°C, and the oil film thickness is reduced from 0.072mm to 0.042mm; the second stage of the load reduction operation starts when the oil film temperature is above 75°C, as shown in the figure below .

[0090]

[0091] Based on the existing technology, the present invention is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com