A test method for secondary grouting strengthening bearing characteristics of broken rock mass

A secondary grouting and characteristic test technology, applied in the direction of strength characteristics, preparation of test samples, and application of stable tension/pressure to test material strength, etc., to achieve the effect of easy operation and reasonable steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

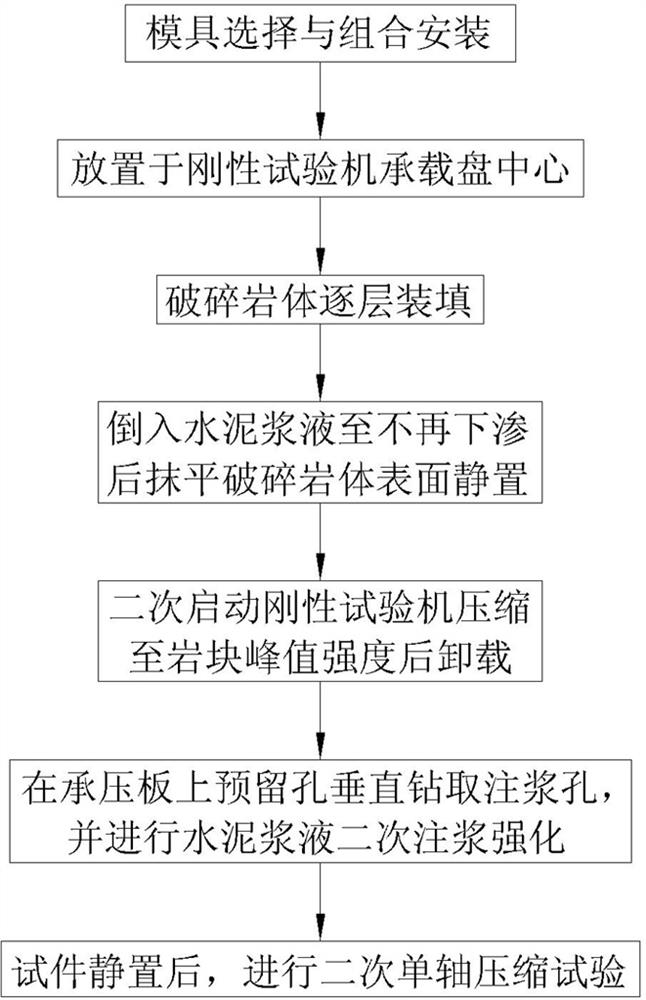

[0021] The invention provides a test method for secondary grouting strengthening bearing characteristics of a broken rock mass.

[0022] Step 1. According to the purpose of the experiment, determine the lithology and particle size of the test, select the shape and size of the mold, and design the number of reserved grouting holes;

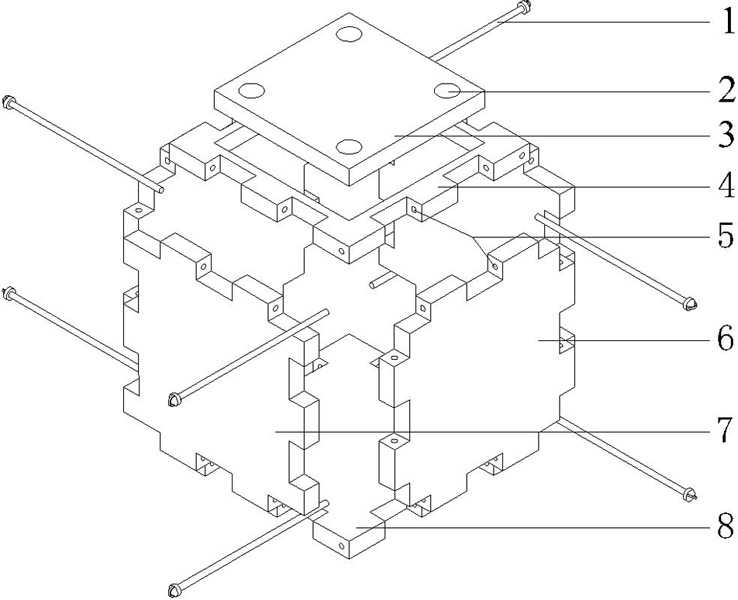

[0023] Step 2, place the bottom plate 8 flat, and then install it with the left and right wall panels 6 and the front and rear baffles 7, insert the fixing pin 1, measure the verticality of the four sides, ensure that the mold size error is not greater than ±0.5mm, insert the top plate 4 and fix it Apply lubricating oil to ensure smooth contact surface with the rock block;

[0024] Step 3, place the assembled mold in the center of the bearing plate of the rigidity testing machine, and use a dynamic tamping machine to fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com