Device for measuring particle distribution in tube nest of fluidized bed heat exchanger according to suspension method

A fluidized bed heat exchanger and internal particle technology, which is applied in measuring devices, particle and sedimentation analysis, particle size analysis, etc. The distribution measurement results are accurate, repeatable, and the measurement effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

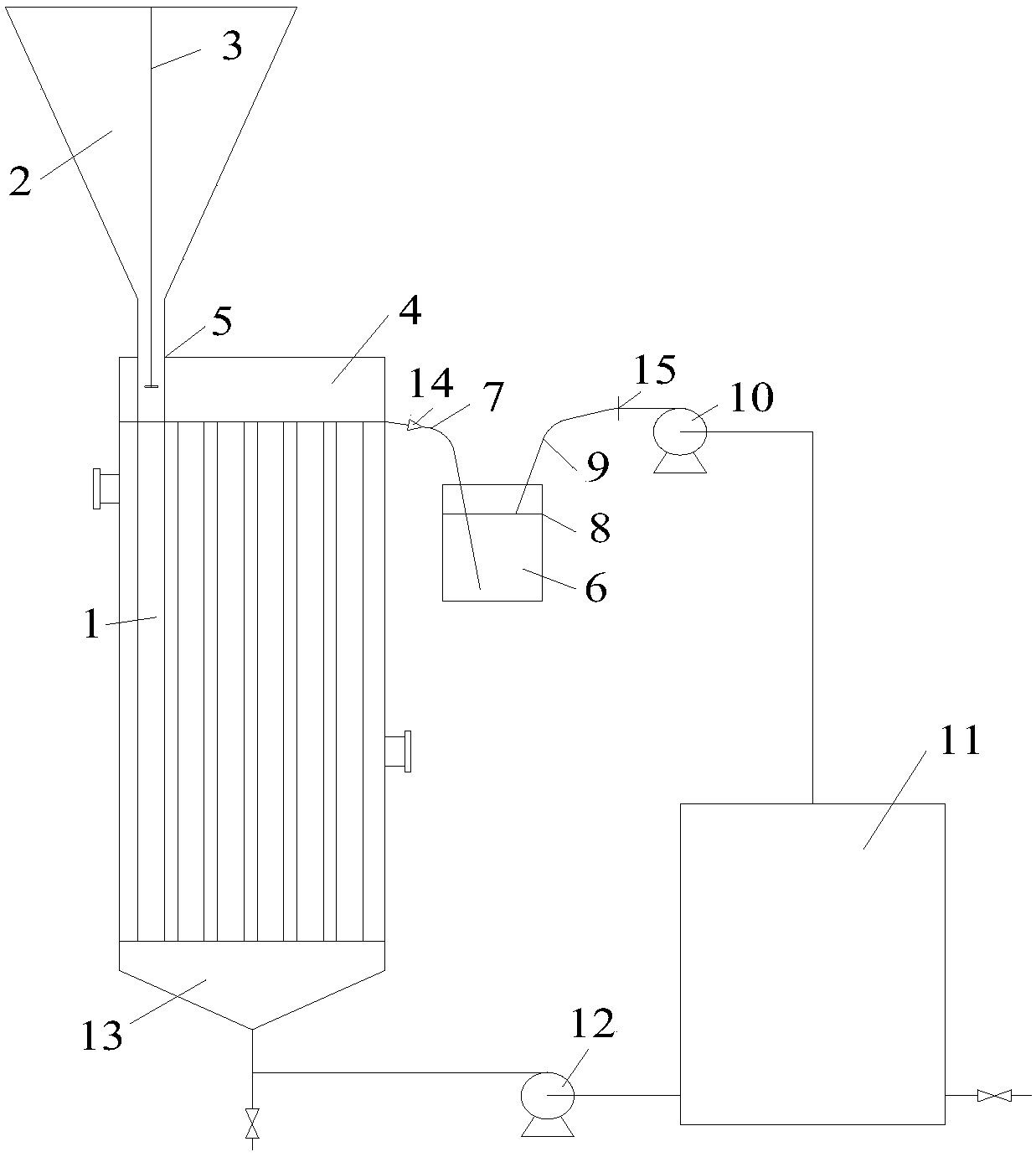

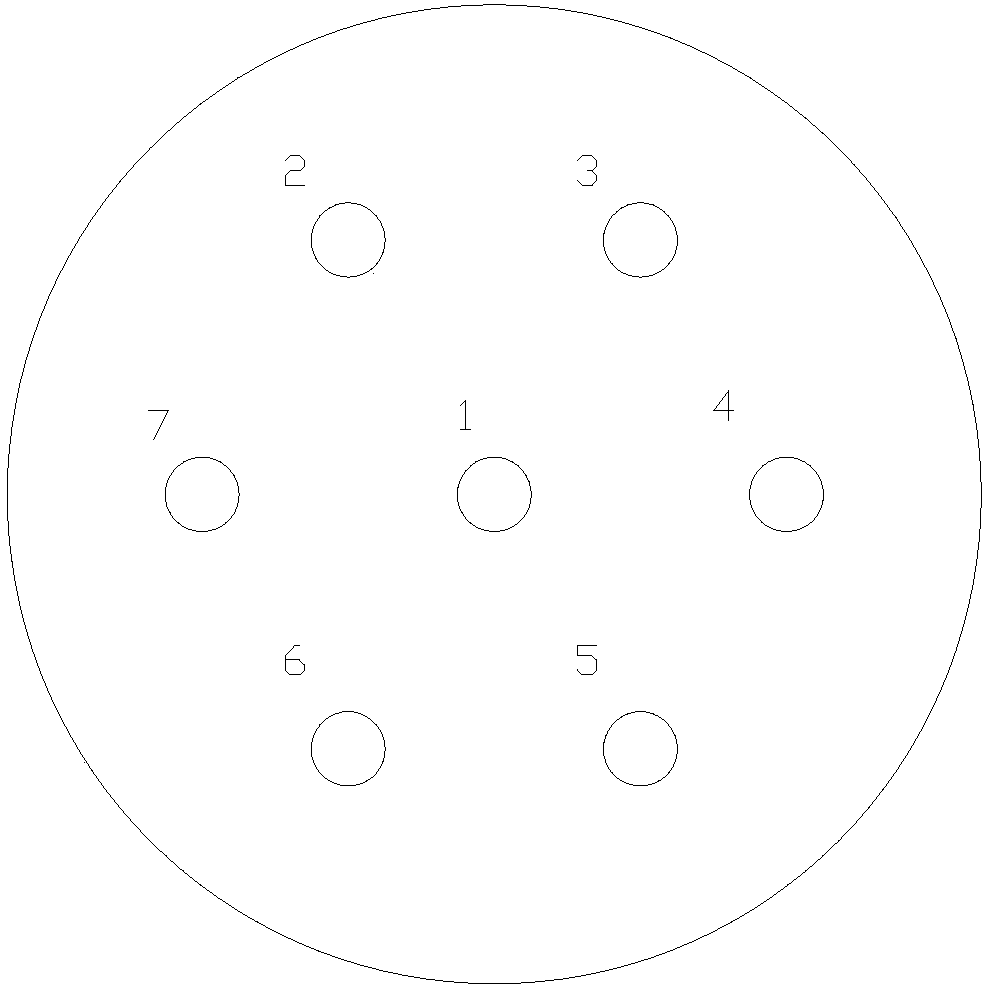

[0032] use figure 1 The device for measuring the particle distribution in the fluidized bed heat exchanger tubes by the suspension method is shown. The diameter of the heat exchanger tube of the device is 250mm, and there are 2 layers of 7 heat exchange tubes inside, 1 in the center layer and 6 in the second layer around it. The roots are arranged in an equilateral triangle, each tube is 1000mm long, and the tube diameter is Φ22×1.5mm. The inner diameter of the small opening of the measuring tube is 19mm, the diameter of the large opening is 400mm, and the height of the variable diameter section is 500mm. The diameter of the sleeve is 400mm, and the height of the sleeve is 30mm. There are two types of sleeves, one is the center opening, and the other is the opening at the concentric circle of the second layer tube section, the opening diameter is 19mm. A large filter screen is installed at 3 / 4 of the height of the particle tank, and the hole of the large filter screen is 1.5...

Embodiment 2~12

[0034]The same suspension method as in Example 1 is used to measure the particle distribution in the tubes of the fluidized bed heat exchanger. The diameter of the heat exchanger tube of the device is 250mm, and there are 7 heat exchange tubes in 2 layers, and 1 in the center layer. There are 6 tubes on the second layer around them, arranged in an equilateral triangle, each tube is 1000mm long, and the tube diameter is Φ22×1.5mm. The inner diameter of the small mouth of the measuring tube is 19mm, and the diameter of the large mouth is 400mm. The sleeve diameter is 400mm. There are two types of sleeves, one is the center opening, and the other is the opening at the concentric circle of the second layer tube section, the opening diameter is 19mm. Large filter mesh hole 1.5mm. Small filter mesh hole 1.5mm. Change the height of the variable diameter section of the measuring tube (height measurement), the height of the sleeve (tube height) 30mm, the ratio of the installation po...

Embodiment 13

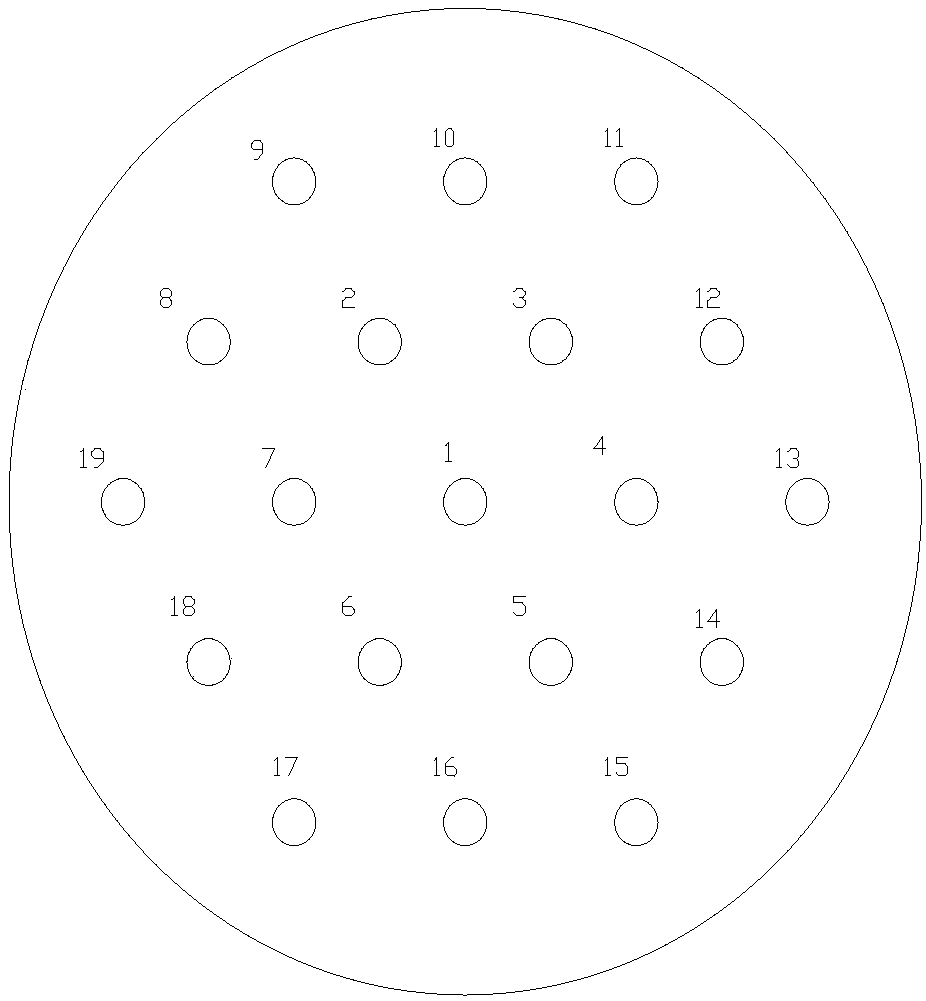

[0040] The same suspension method as in Example 1 is used to measure the particle distribution in the tubes of the fluidized bed heat exchanger. The tube diameter of the heat exchanger is 400 mm, and there are 19 heat exchange tubes in 3 layers, and one in the center layer. There are 6 tubes in the second layer around and 12 tubes in the third layer of the outermost layer, arranged in an equilateral triangle, each tube is 1000mm long, and the tube diameter is Φ22×1.5mm. The inner diameter of the small opening of the measuring tube is 19mm, the diameter of the large opening is 400mm, and the height of the variable diameter section is 500mm. The diameter of the sleeve is 400mm, and the height of the sleeve is 30mm. There are three types of sleeves, one is the center hole, the second is the hole at the concentric circle of the second layer tube section, and the other is the third layer tube tube section center concentric circle. Aperture 19mm. A large filter screen is installed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube height | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com