Three-dimensional simulation training system for ultra-high voltage main equipment

A technology of 3D simulation and training system, which is applied in the field of 3D simulation training system for UHV main equipment, can solve the problems of poor pertinence and timeliness, long training cycle, and difficult training, etc., to enhance hands-on ability, improve intuitiveness, and train good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

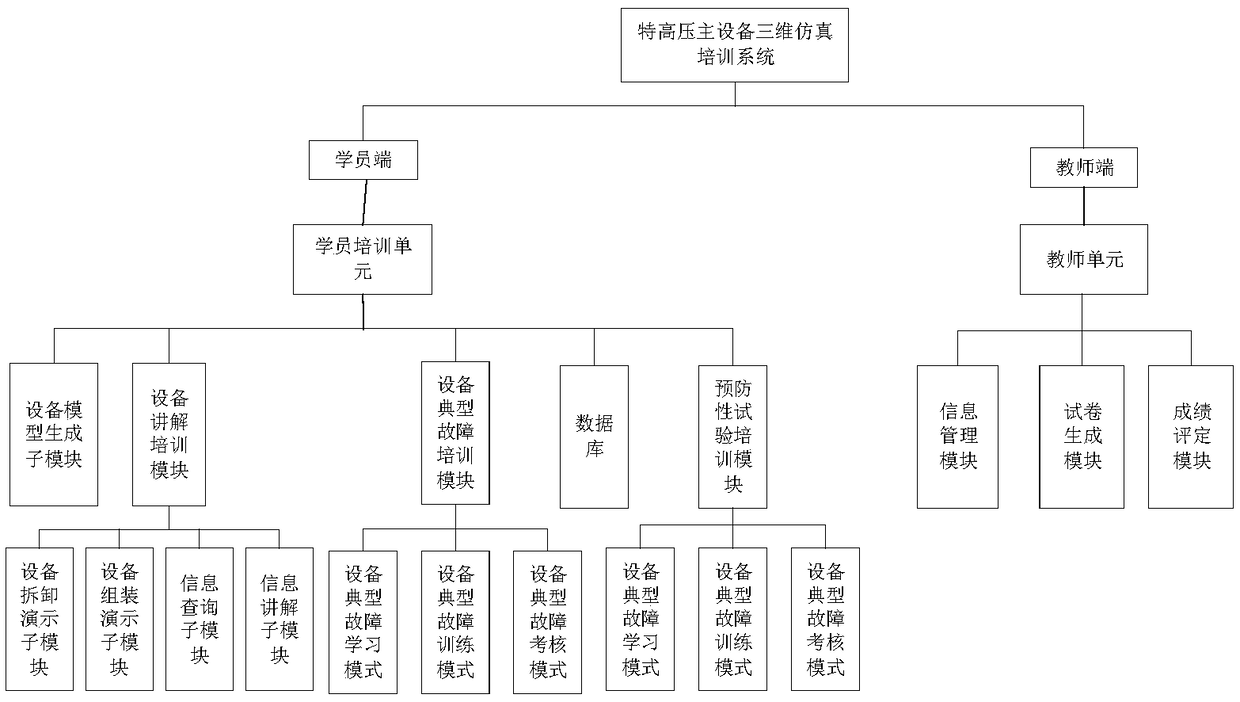

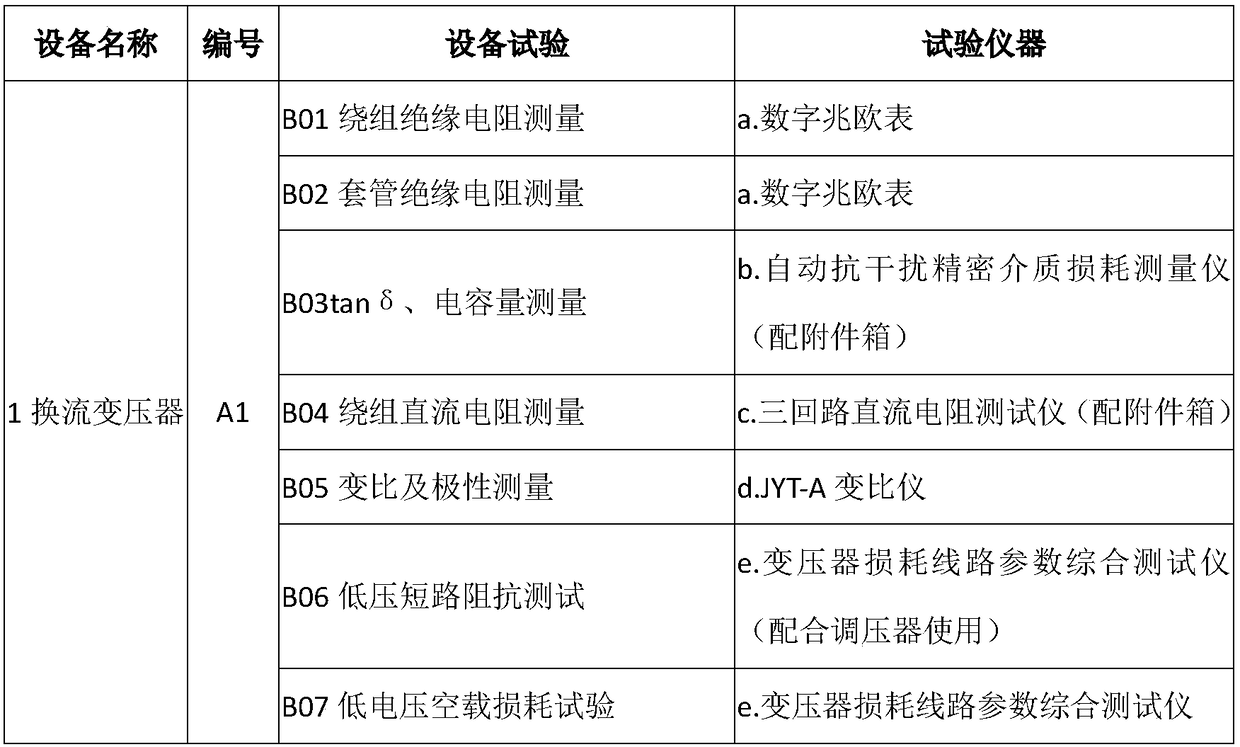

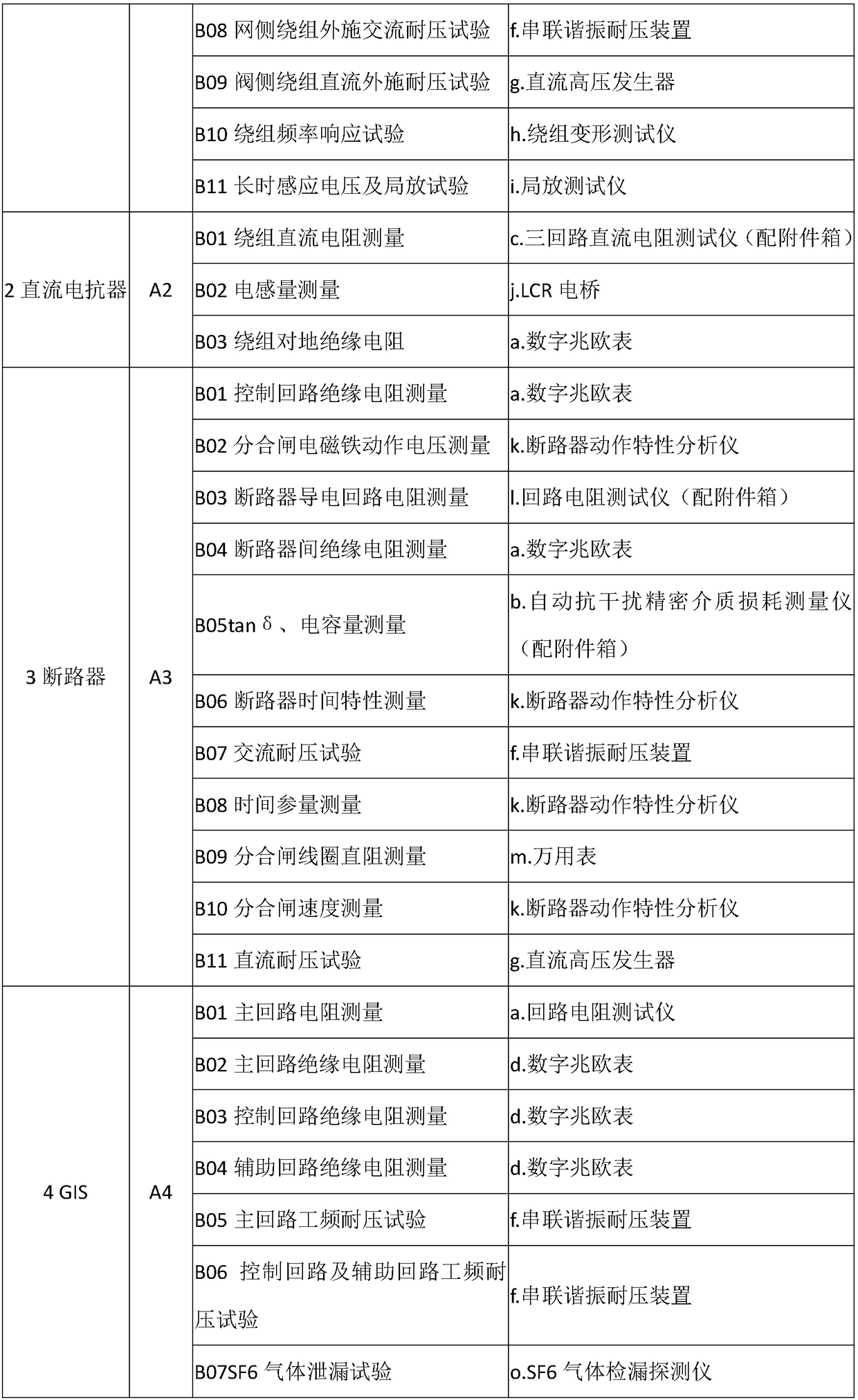

[0040] see figure 1 As shown, the embodiment of the present invention provides a three-dimensional simulation training system for UHV main equipment, mainly for adjusting cameras, converter valves, converters, 1000kV main transformers, reactors, capacitors, 1000kVGIS high-voltage power distribution devices, 1000kV circuit breakers, Create a three-dimensional model of UHV main equipment such as transformers and capacitors, systematically display the internal structure of the equipment and explain its functions, and provide technical training for main equipment testing to realize equipment testing and simulation of typical fault defects.

[0041] It mainly includes the following training content:

[0042] 1. Equipment disassembly and assembly, equipment structure explanation;

[0043] 2. Equipment preventive test and operation explanation of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com