Composite structural slab

A composite structure and panel technology, which is applied to synthetic resin layered products, furniture parts, household appliances, etc., can solve the problems of complex processing, enhanced strength, and high cost, and achieve simplified manufacturing process, enhanced overall load-carrying capacity, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Descriptions related to directions in any embodiment herein, such as "up / down", "left / right", "top / bottom", etc., are based on the direction of the drawings themselves for the convenience of description, and will not limitations on the invention.

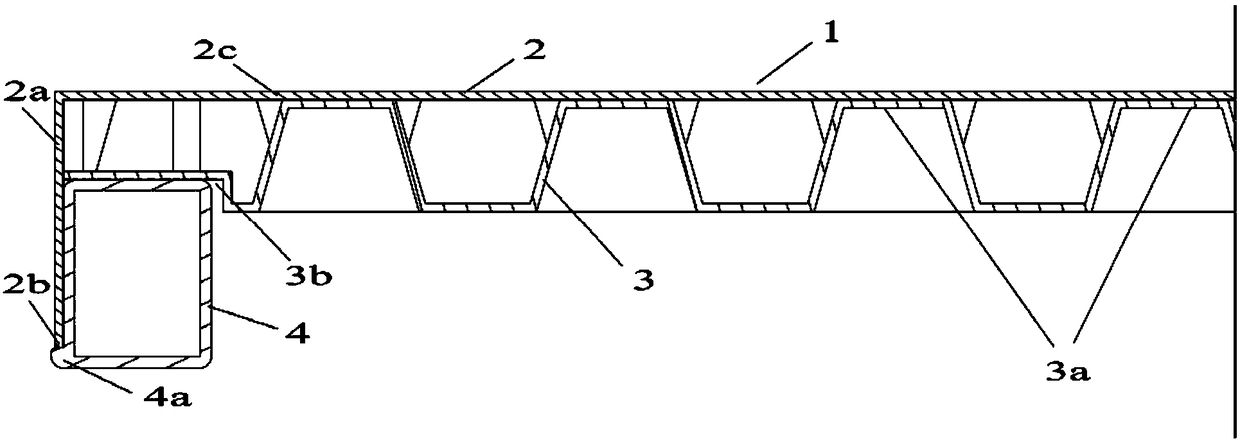

[0040] in such as figure 1 and figure 2 In the shown first embodiment according to the invention, the composite structural panel 1 is mainly composed of three parts: the panel 2 facing outwards in normal use, and the panel 2 fixedly connected to the panel by adhesive or other feasible means. The bottom plate 3 , and the reinforcement 4 provided at the peripheral portions of the panel 2 and the bottom plate 3 .

[0041] The panel 2 has a main body portion 2c substantially on the same plane and a peripheral portion 2a formed by bending the main body portion 2c downward to surround the main body portion, and the panel 2 has an upper surface facing outwards in normal use and The lower surface facing inwards in normal use. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com