Horizontally pre-tightened and combined wound plate frame type press machine rack

A plate-and-frame, press technology, applied in the field of press frames, can solve the problems of matching load bearing capacity, reducing actual bearing capacity, and large gap, achieving high overall bearing capacity, reducing production costs, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

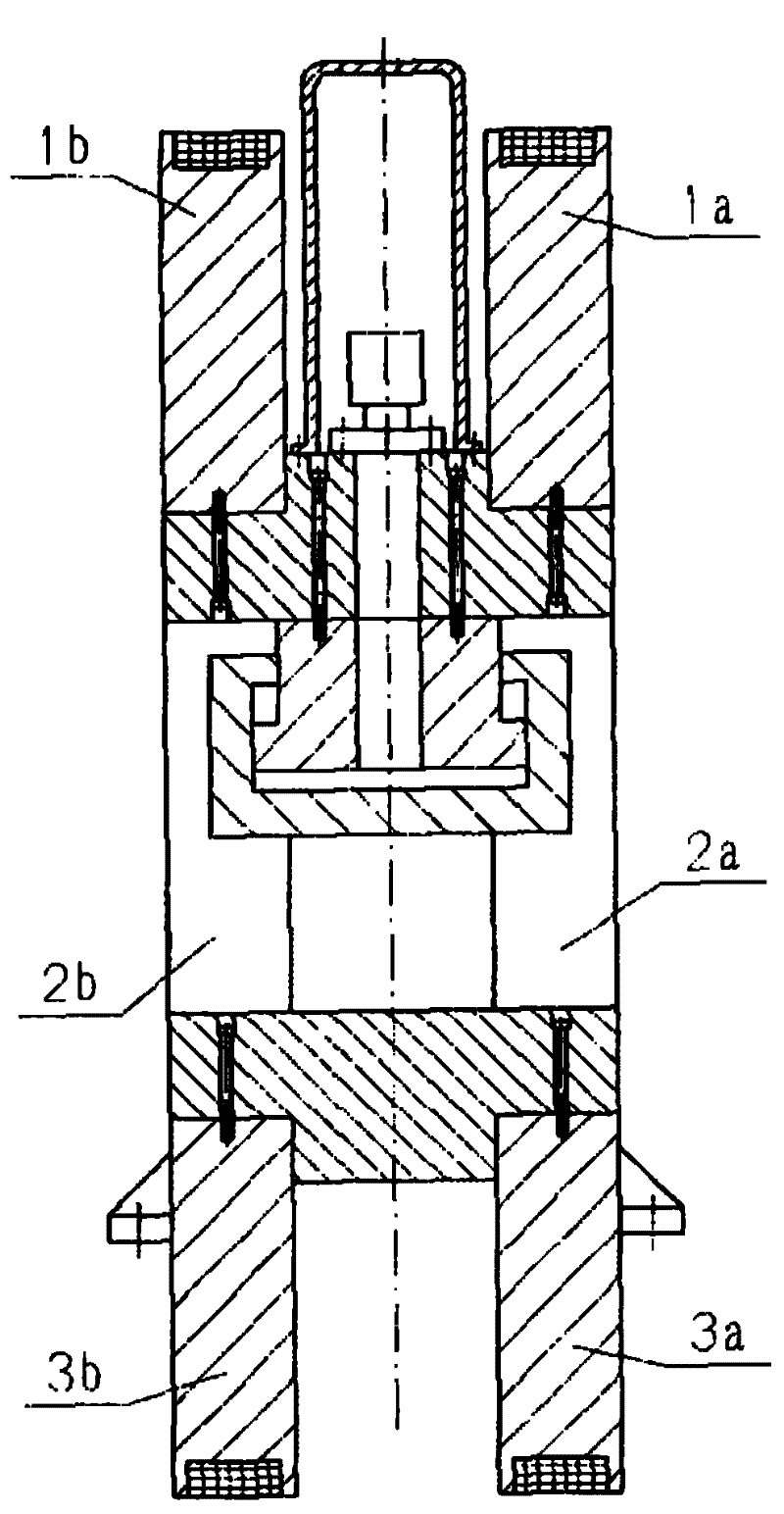

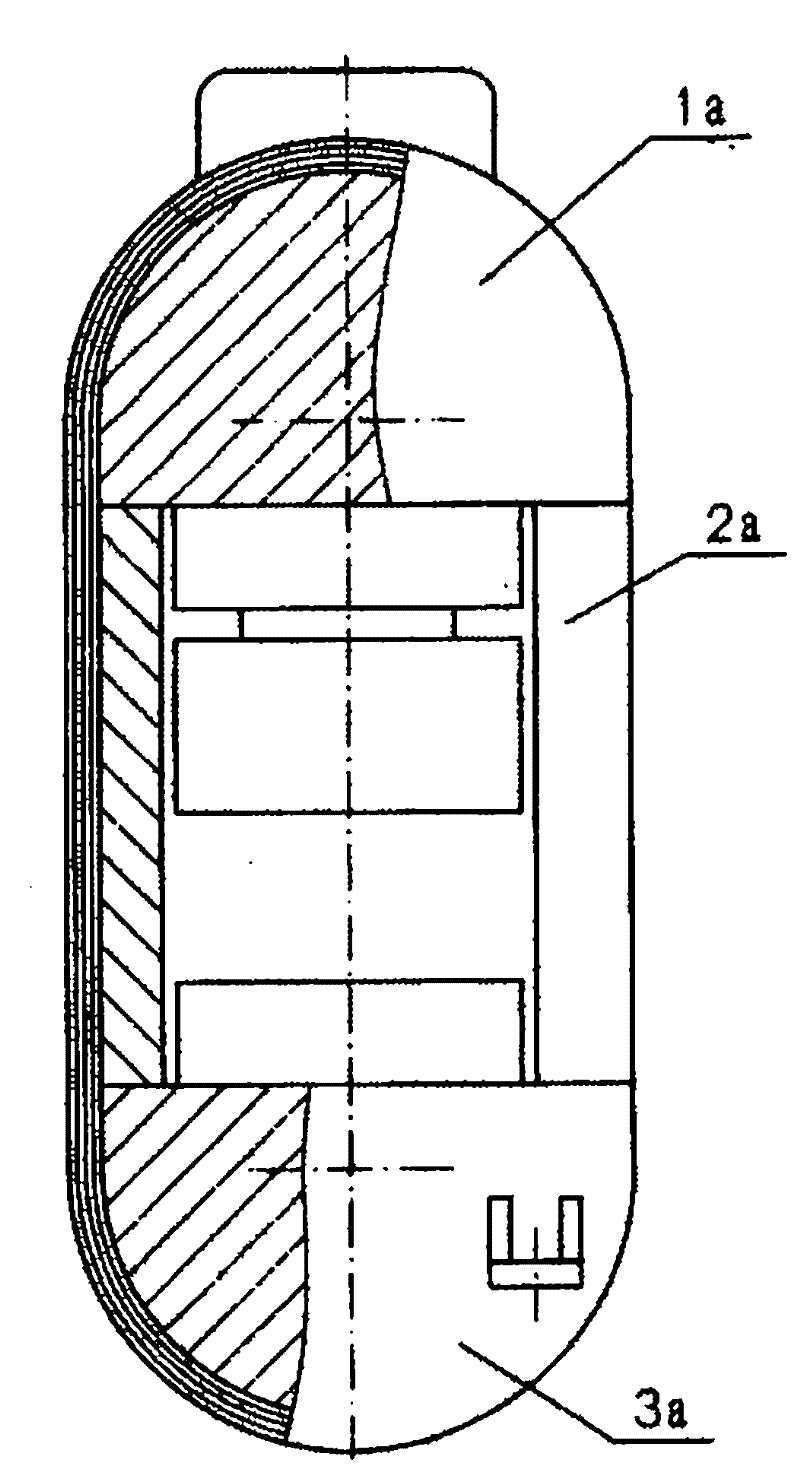

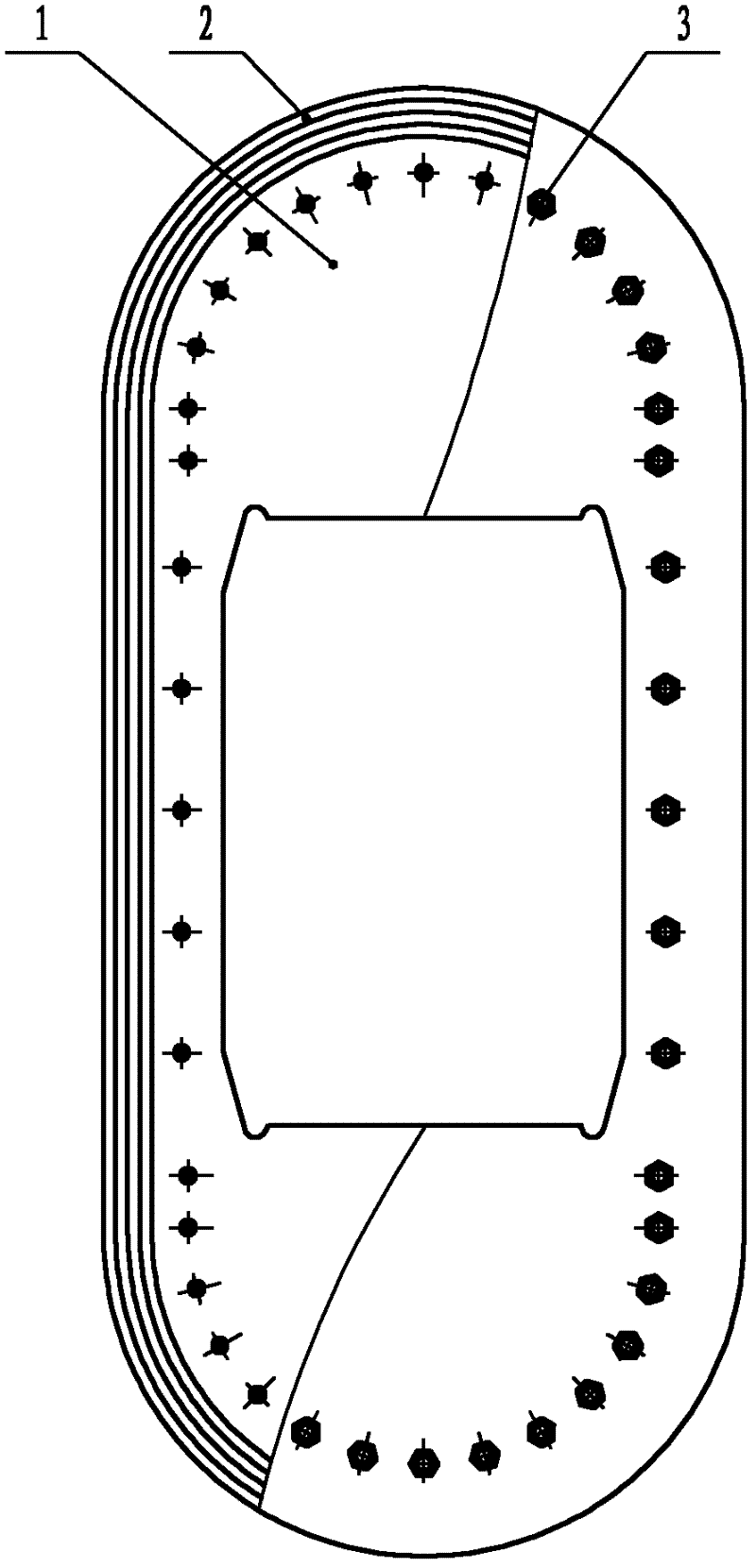

[0032] Such as image 3 , Figure 5 , Figure 6 As shown, a horizontally pre-tightened combined winding plate and frame press frame includes a main frame, which is composed of two front and rear plate frames and a connecting frame 5 bridging the front and rear plate frames. The front and rear frames respectively include plural The independent plate frame structure, 1, the plate frame member 1 is hollow on the front and back, and each plate frame member 1 is a steel wire wound prestressed structure, and the steel wire 2 wound along the outer peripheral surface of the plate frame member 1 completes the height of the plate frame member. And the pre-tightening in the width direction, the plate frame structure, 1 through multiple sets of high-strength bolt pre-tightening mechanisms distributed on the front and back of the plate frame member 3 transverse pre-tightening fixation to form the front and rear plate frames. The high-strength preload mechanism 3 is composed of high-stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com