Method for reducing stress concentration of perforated structure of brittle material

A brittle material and stress concentration technology, applied in the field of brittle materials, can solve problems affecting functional integrity, structural failure, shortened service life, etc., and achieve the effects of improving overall bearing capacity, reducing stress concentration, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

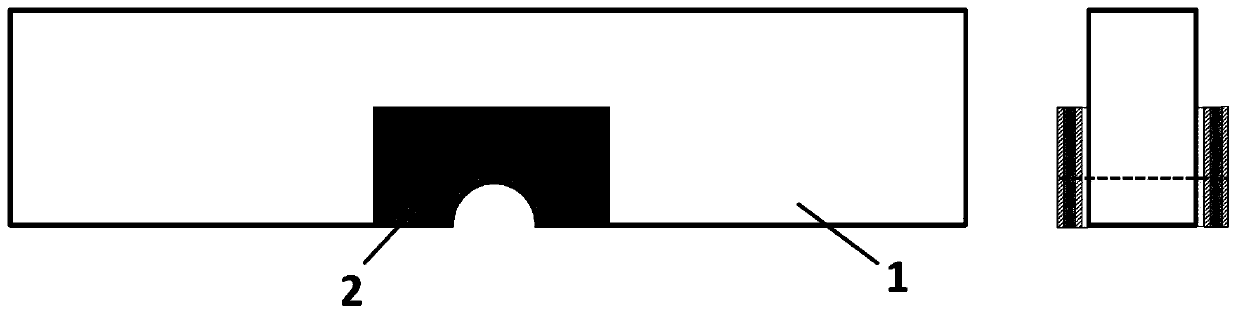

[0028] combined with figure 1 As shown, a method for reducing the stress concentration of the brittle particle composite opening structure and its structure, because the position of the opening has many possibilities, the opening of this embodiment is an edge opening and the cross section of the opening is Semicircle, the specific steps are as follows:

[0029] Step 1: Surface pretreatment, gently wipe the surface of the hole with absolute ethanol to remove surface dirt and dust;

[0030] Step 2: Prepare the conformal patch 2, apply top glue on the PTFE board, spread the cut carbon fiber cloth on the PTFE board, paint the top glue on the surface of the carbon fiber cloth again and cover it with the PTFE board. Then put the mounted carbon fiber cloth together with the upper and lower two PTFE boards into a vacuum bag, draw the vacuum and let it stand until the surface glue is solidified. The vacuum degree of the drawn vacuum is -80kPa. Cut a square patch with a side length of...

Embodiment 2

[0041] On the basis of Example 1, if the arc length of the cross-section of the opening is larger than a semicircle, two patches should be removed from the carbon fiber plate, and then the hole should be opened to obtain a conformal patch 2, which should be pasted according to the opening. Trimming; if the arc length of the cross-section of the opening is less than a semicircle, only one patch needs to be taken, and then the patch is cut into two identical conformal patches matching the opening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com