Color steel plate transporting trolley capable of flexibly steering

A technology for transporting trolleys and color steel plates, which is applied in the direction of transportation and packaging, trolleys, motor vehicles, etc. It can solve the problems of difficult handling, narrow aisles, and difficult labor, so as to reduce the labor intensity of handling, improve work efficiency, and have fewer constraints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

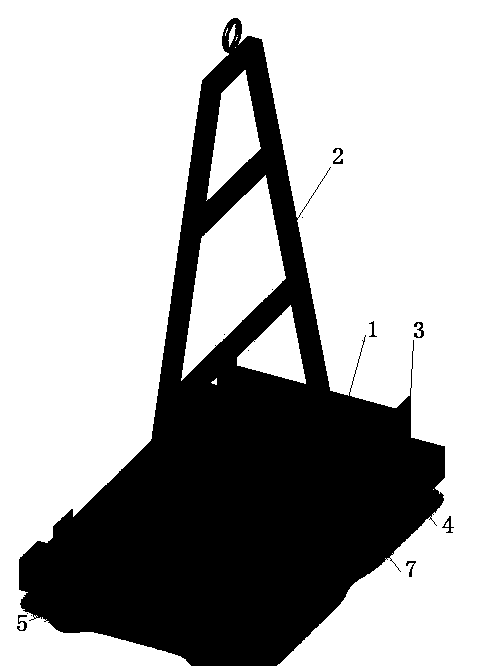

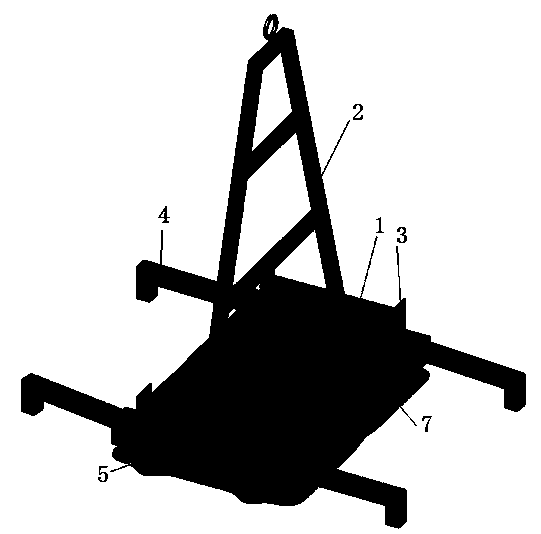

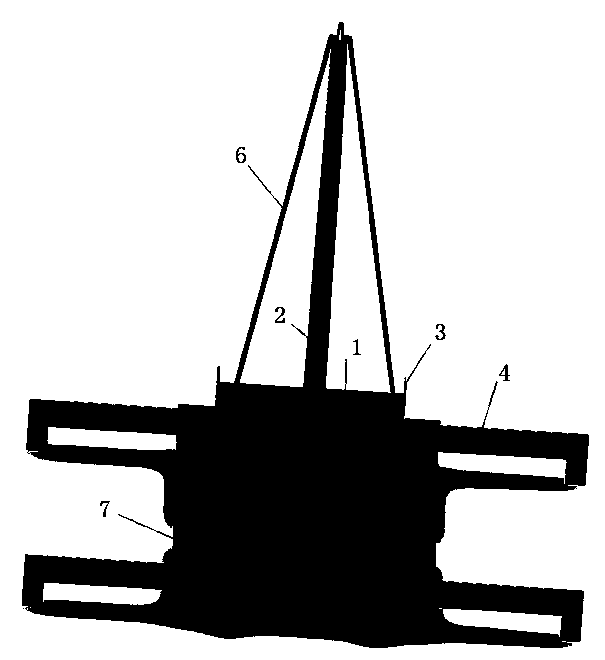

[0019] The present invention comprises a flat base 1, on which a railing 2 perpendicular to the flat base 1 is arranged, and on both sides of the flat base 1 there are counter-colouring bars arranged parallel to the railing 2 respectively. The limiting plate 3 for the limiting effect of the steel plate;

[0020] Both sides of the flat base 1 are also provided with stabilizing legs 4 respectively, and the stabilizing legs 4 are rotatably connected to the flat base 1, and when the stabilizing legs 4 are rotated out, they are arranged vertically with the limiting plate 3 as a flat base 1 extending to both sides, when the stable bracket 4 is turned back, it is in contact with the end surfaces on both sides of the flat base 1 and is arranged parallel to the limiting plate 3;

[0021] Universal wheels 5 are arranged below the flat base 1 .

[0022] The top of the railing 2 is provided with a hanging ring 2, and a binding strap 6 is provided to pass through the hanging ring 2 and ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com