Washing machine outer tub and washing machine inner and outer tub assembly method

A washing machine and outer tub technology, which is applied in the field of washing machine outer tub and washing machine inner and outer tub assembly, which can solve the problems of high cost of press-fitting equipment, complex positioning and force-bearing structure, achieve good support effect, prevent front bearing damage, and improve operation process. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

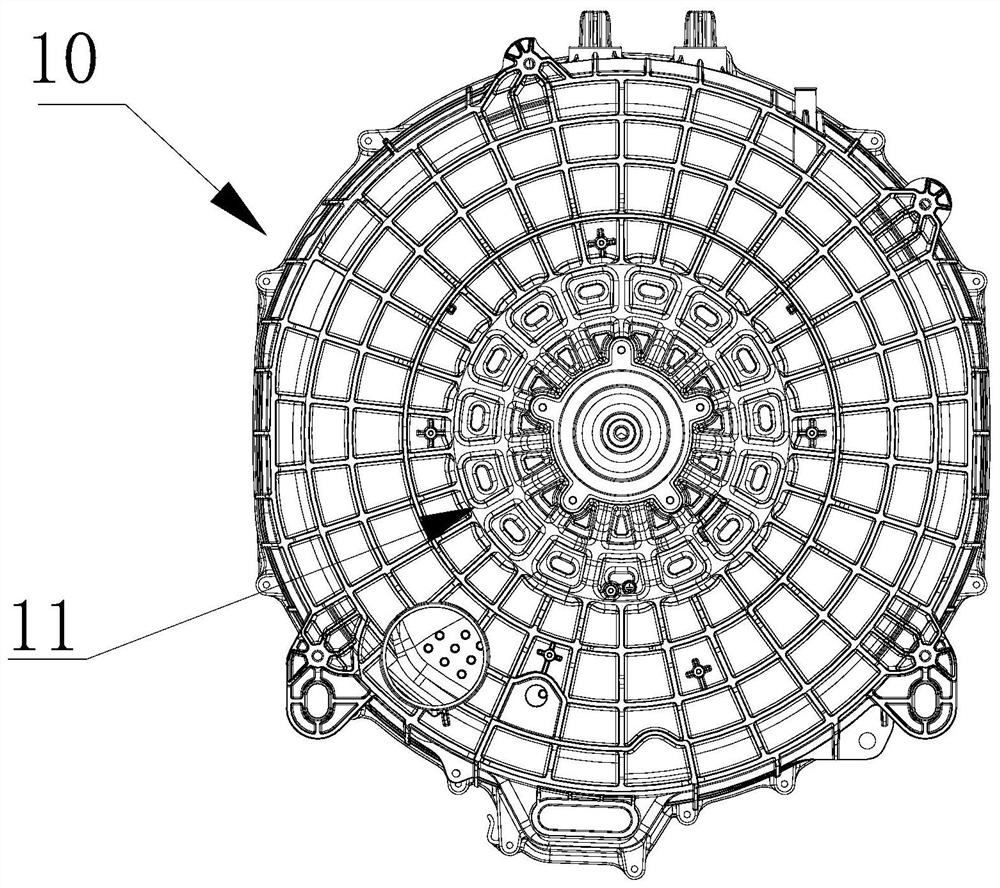

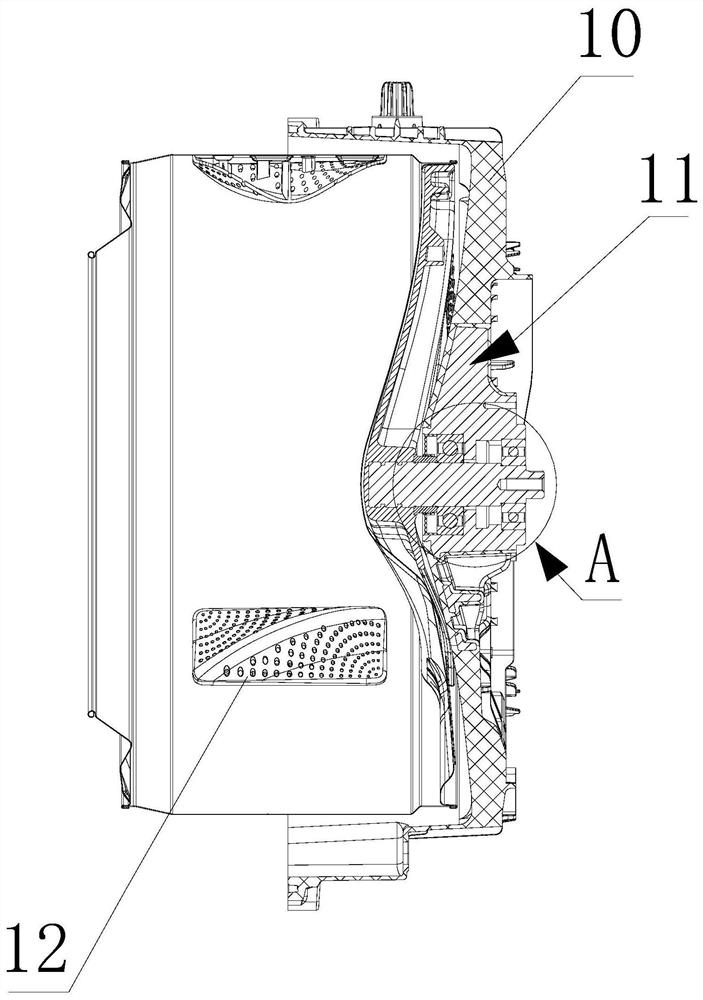

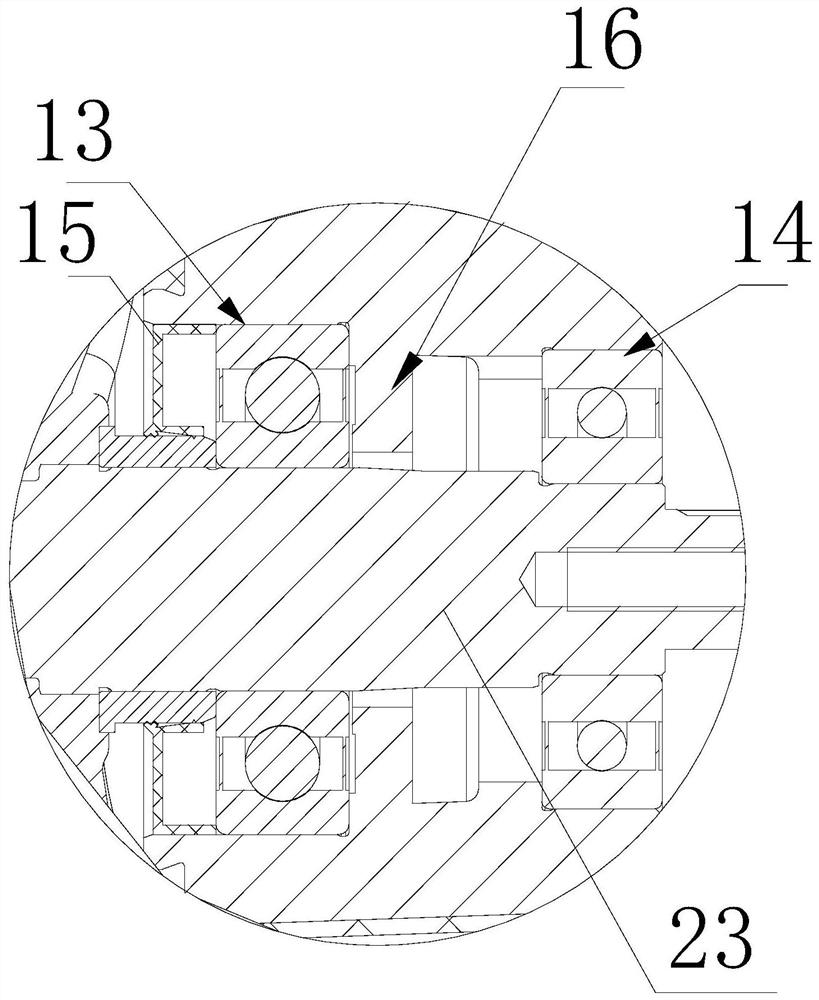

[0059] see Figure 1-Figure 6 As shown, the present embodiment provides a washing machine outer tub 10, the bottom of which is provided with a bearing support seat 11, the bearing support seat 11 is provided with a bearing chamber, and an oil seal 15, a front bearing 13 and a rear bearing are installed in the bearing chamber. 14. The bearing chamber is provided with a first support structure 16 for providing support to the inner ring of the front bearing 13 and preventing the inner ring of the front bearing 13 from being damaged by force during the installation of the inner barrel shaft 23 .

[0060] In the above scheme, by setting the first support structure 16 in the bearing chamber, it is beneficial to provide the bearing inner ring support force during the installation of the inner barrel shaft 23, and solve the problem caused by the complicated positioning and force-bearing structure of the current tight-fit bearing press-fitting equipment. The cost of press-fitting equip...

Embodiment 2

[0075] This embodiment provides a washing machine inner and outer tub 10 assembly method applied to the washing machine outer tub 10 in the first embodiment, wherein, because the present invention is provided in the bearing chamber to provide support for the inner ring of the front bearing 13, preventing the installation of the inner tub During the process of the shaft 23, the inner ring of the front bearing 13 is stressed and the first support structure 16 is damaged, thereby facilitating press-fitting, effectively reducing equipment costs, and simplifying the assembly method of the inner and outer barrels 10 . The method for assembling the inner and outer tubs 10 includes the following steps:

[0076] S1, sequentially press-fit the front bearing 13 and the oil seal 15 into the bearing chamber in the bearing seat, so that the front bearing 13 is fixed in the front bearing chamber 17, and the oil seal 15 is fixed on the outside of the front bearing 13;

[0077] S2, the rear be...

Embodiment 3

[0080] see figure 1 as well as Figure 7-Figure 9As shown, the present embodiment provides another washing machine outer tub 10, the bottom of which is provided with a bearing support seat 11, the bearing support seat 11 is provided with a bearing chamber, and an oil seal 15, a front bearing 13 and a rear bearing chamber are installed in the bearing chamber. Bearing 14, the bearing chamber is provided with a first support structure 16 for providing support to the inner ring of the front bearing 13 to prevent the inner ring of the front bearing 13 from being damaged by force during the process of installing the inner barrel shaft 23. The first supporting structure 16 includes the abutment pieces 24 arranged at the two ends of the bearing chamber respectively abutting against the inner ring of the front bearing 13 and the inner ring of the rear bearing 14. 23 in the process, accept the external structure to provide support;

[0081] Preferably, the bearing chamber includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com