Electricity leakage prevention structure

A leakage prevention and current detection technology, applied in lighting and heating equipment, fluid heaters, etc., can solve problems such as imperfect design, human electric shock accidents, and lack of notification of danger sources, and achieve low manufacturing costs, easy production and processing, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

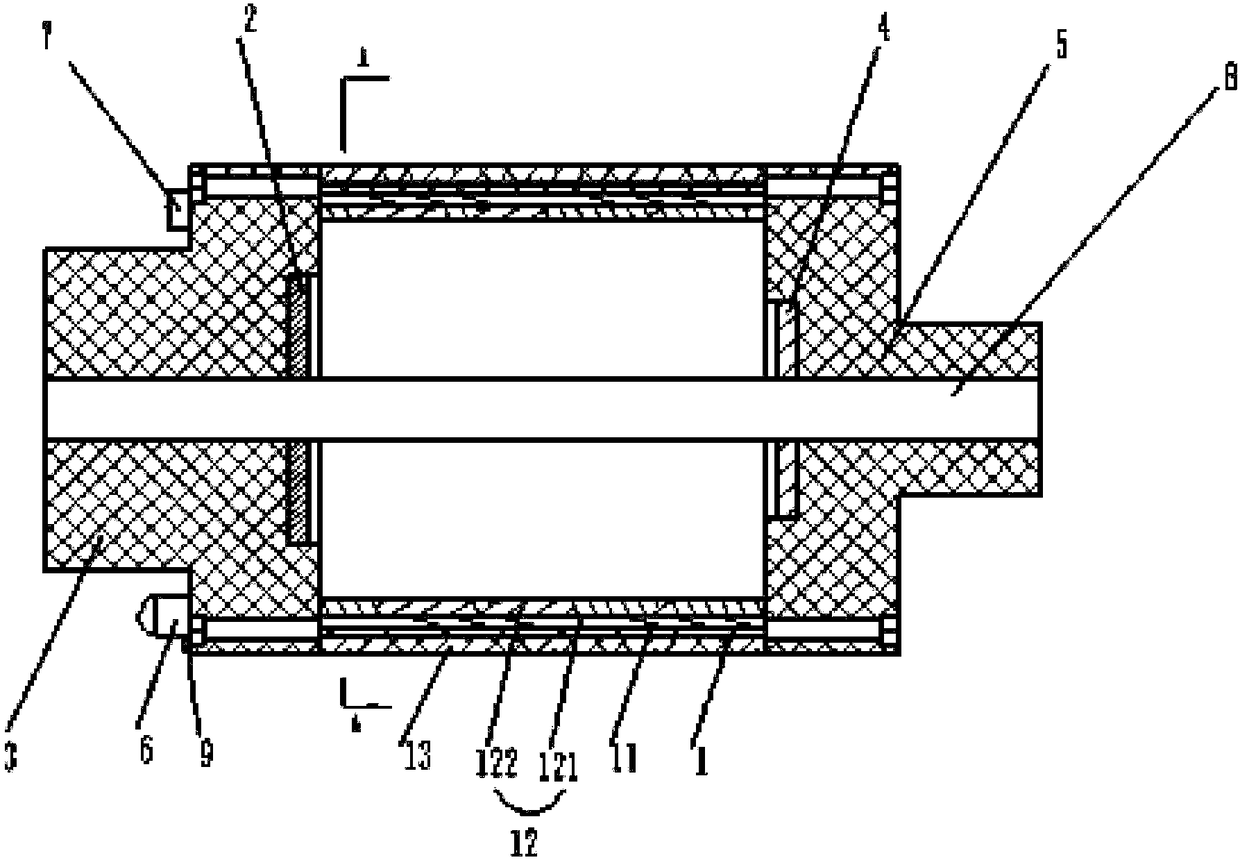

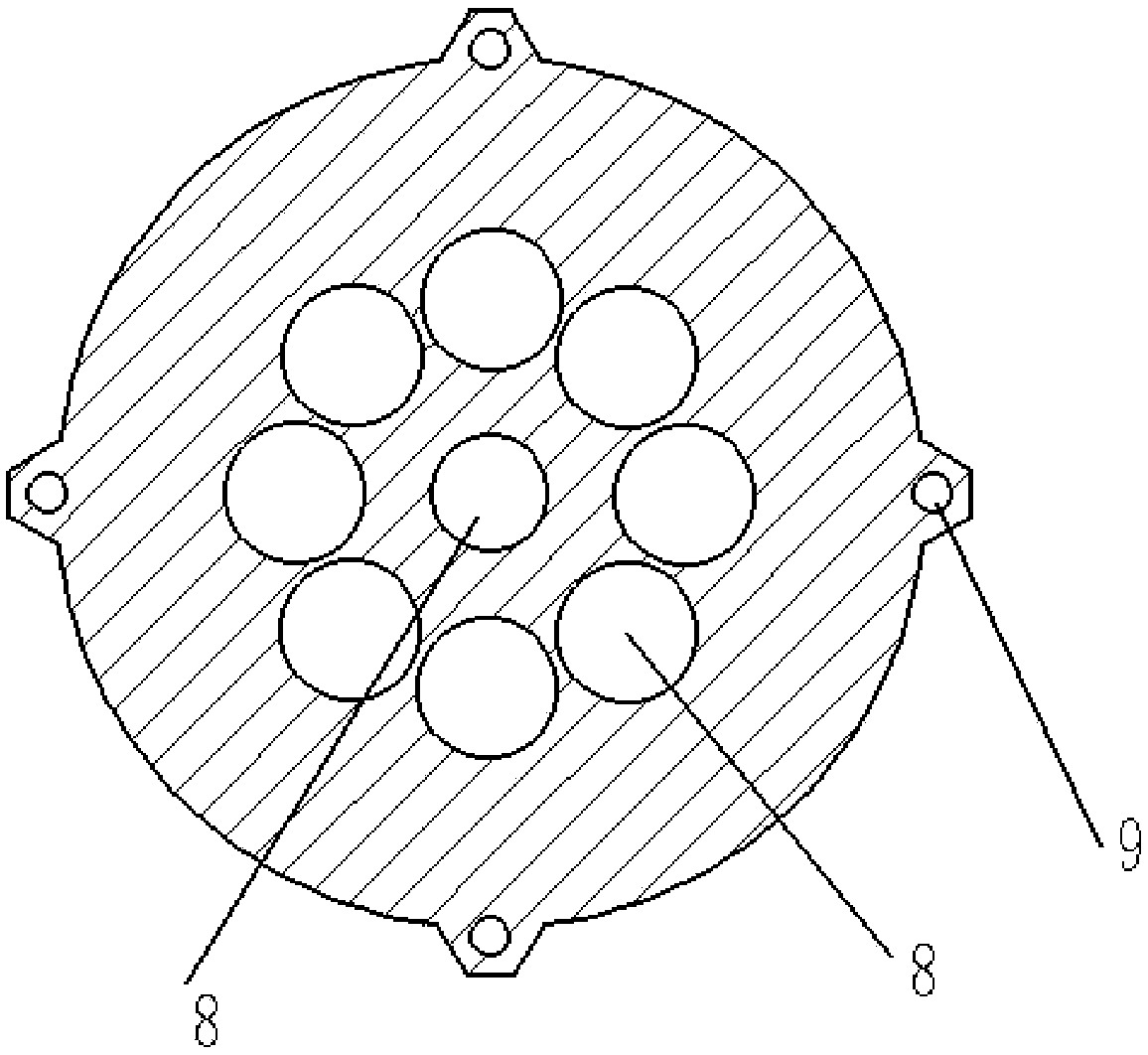

[0024] like figure 1 As shown, a leakage prevention structure includes a housing 1, an upper sealing cover 2, an upper end cover 3, a lower sealing cover 4, a lower end cover 5, an audible and visual alarm 6 and a temperature sensor 7; wherein the housing 1 is Stainless steel seamless pipe body, the inner wall of the shell 1 is provided with a corrosion-resistant layer 12, and the outer wall is covered with an insulating layer 11 and a heat insulating layer 13 in turn; the shell 1 is also provided with 9 rubber hoses, which are connected end to end And in series to form a 400mm folding reciprocating flow channel 8, such as figure 2 As shown, ensure that the water resistance is large enough to actively prevent environmental leakage.

[0025] Specifically, the insulating layer 11 is a silicone rubber insulating layer with a thickness of 3mm-5mm; the corrosion-resistant layer 12 is a plastic layer 122 and a rubber buffer layer 121 covered from the inside to the outside, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com