Fuel cell press

A technology of fuel cells and compressors, which is applied in the direction of fuel cells, circuits, electrical components, etc., and can solve problems such as difficult assembly of various fuel cells and difficult precise stroke control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

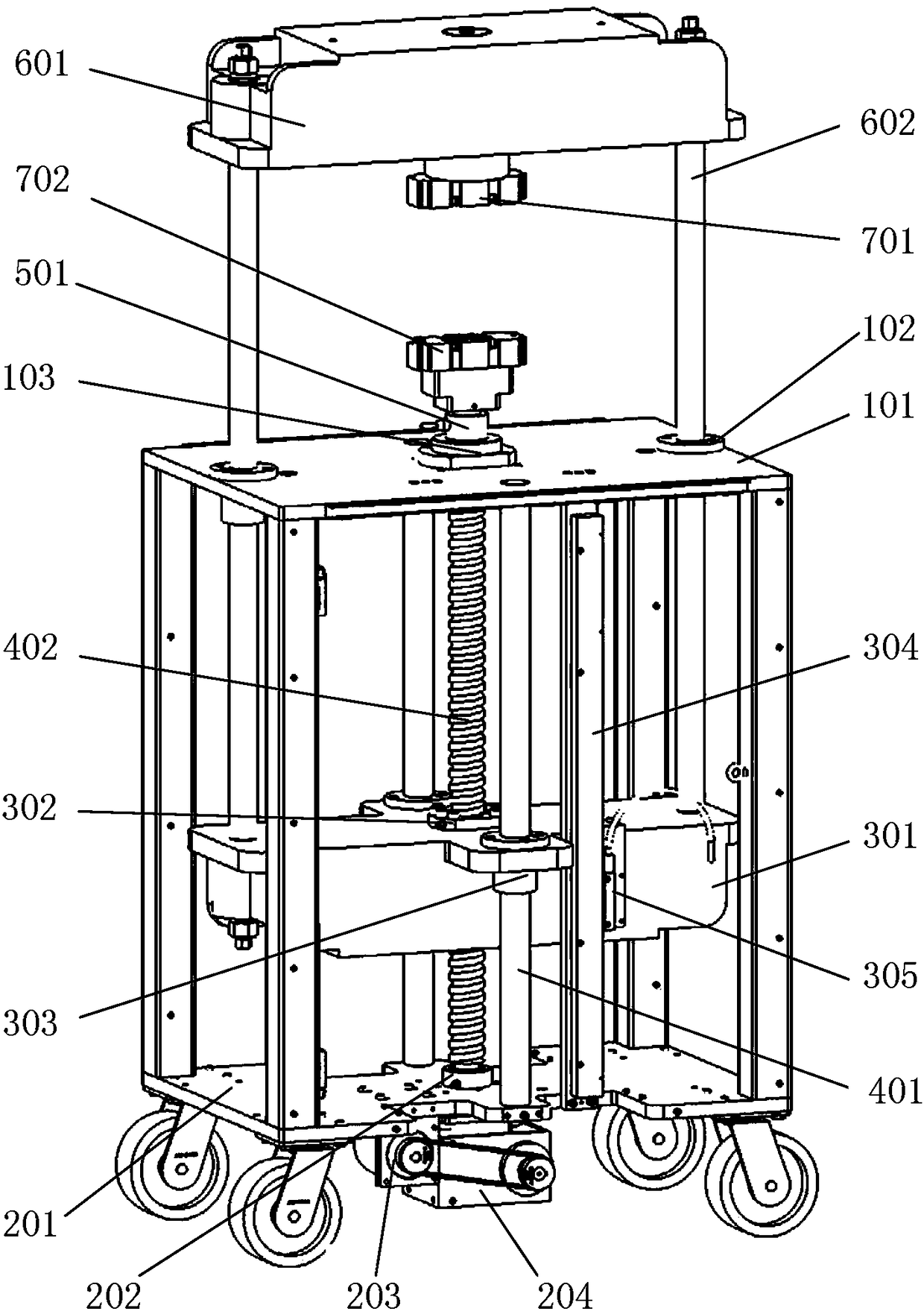

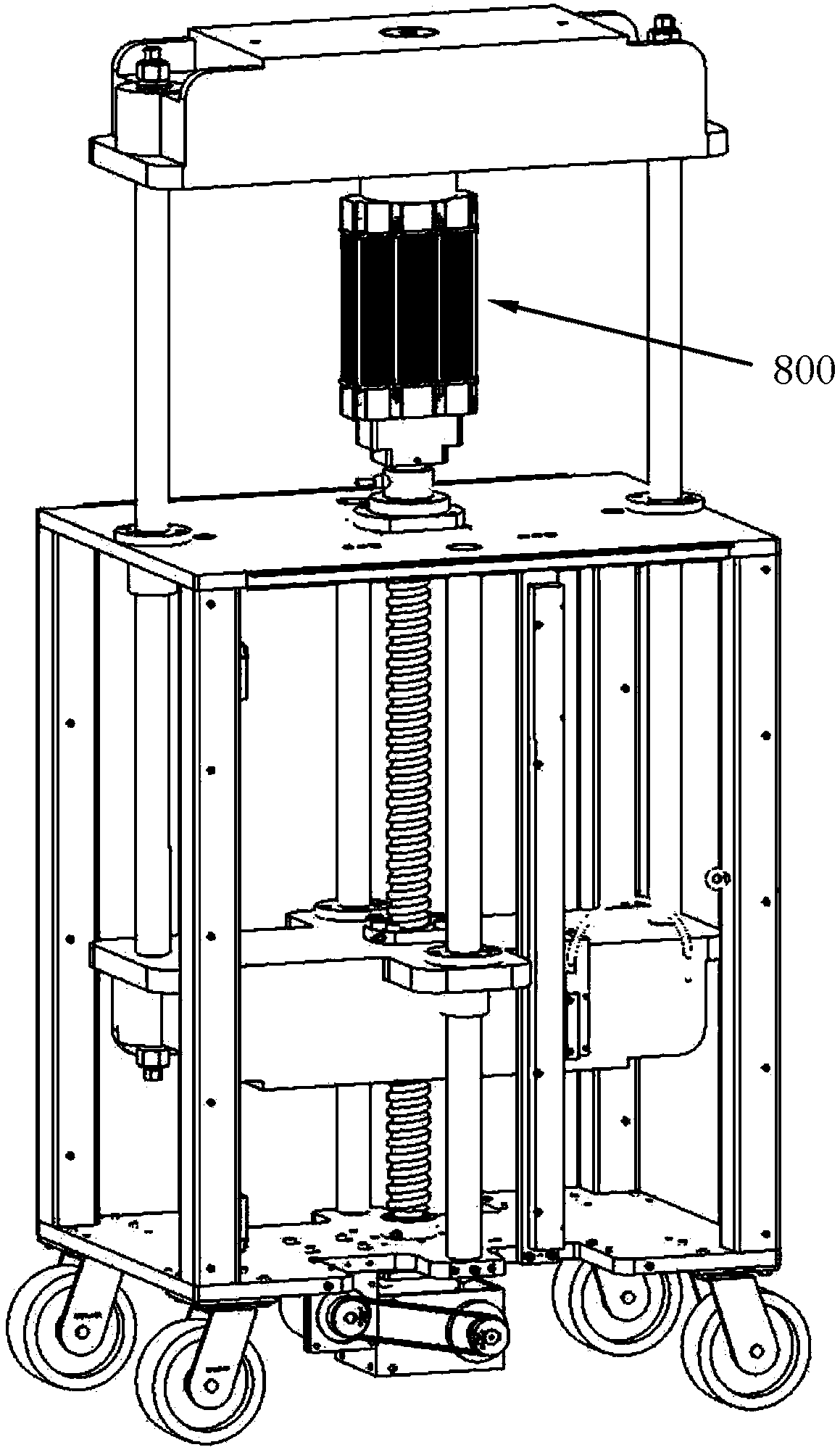

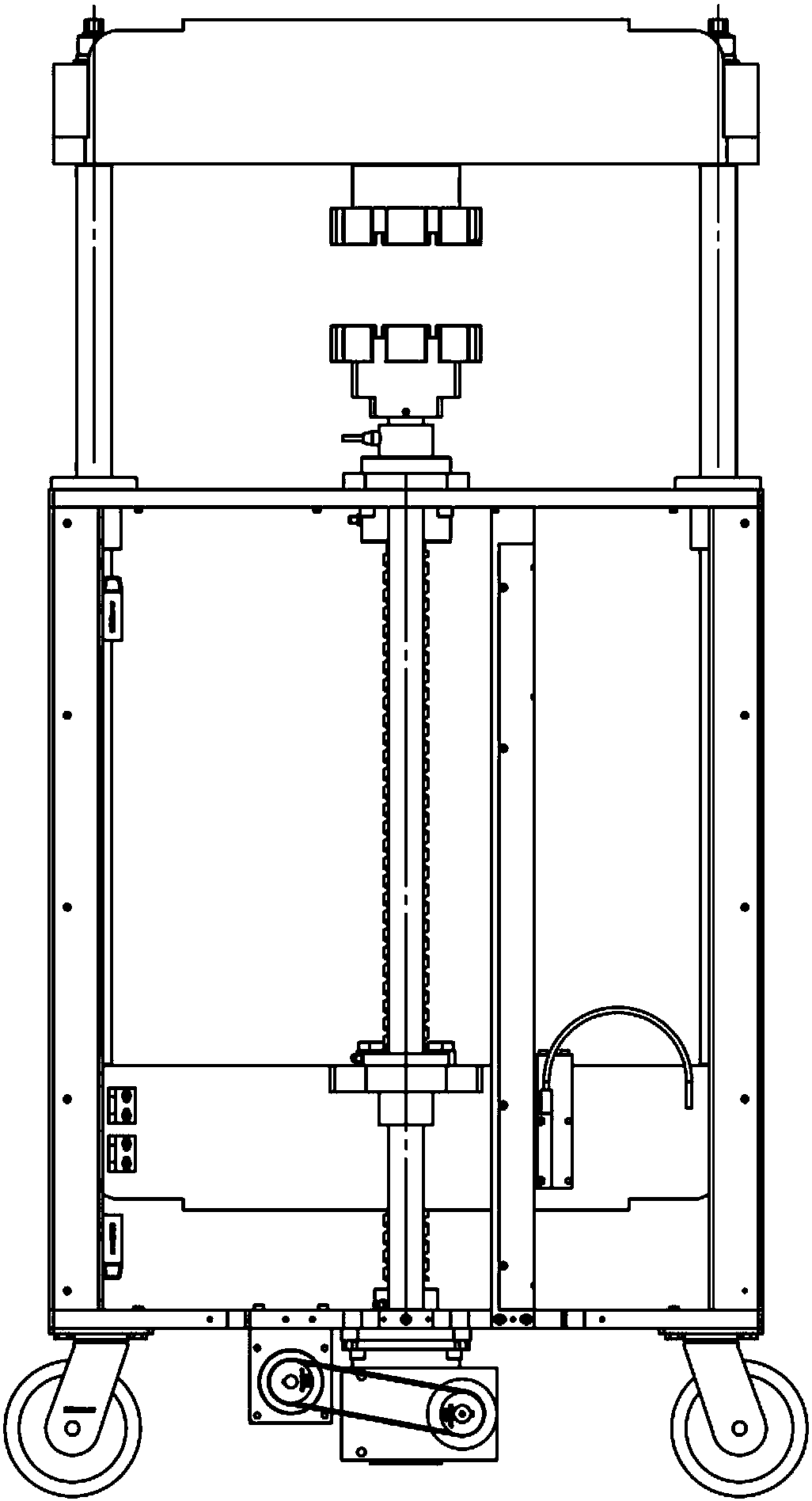

[0028] Figure 1-5 As an embodiment of the present invention, the fuel cell press includes a frame, a power device, a pressure transmission device, an upper mold 701, a lower mold 702, and an electric control system.

[0029] The frame includes a platen 101 and a base plate 201, a guide shaft 401 is arranged between the platen 101 and the base plate 201, a linear grating ruler 304 is arranged between the platen 101 and the base plate 201, and is connected to the base plate 201. The guide shafts 401 are parallel, and a guide fixed bearing 102 and an upper bearing seat 103 are arranged on the platen 101. A deep groove ball bearing and a thrust bearing are arranged in the upper bearing seat 103, and a lower bearing seat 202 is arranged on the bottom plate 201. A deep groove ball bearing and a thrust bearing are arranged in the lower bearing seat 202, the pressure sensor 501 is arranged above the upper bearing seat 103, and the lower mold 702 is arranged above the pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com