Vibration-attenuation installation structure and method of functional module in insertion box and insertion box

A technology of functional modules and installation structures, applied in the directions of support structure installation, mounting plate safety devices, clamping/extracting devices, etc., can solve problems such as unsolved guide rail problems, inability to tighten bolts, etc. Simple, vibration-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

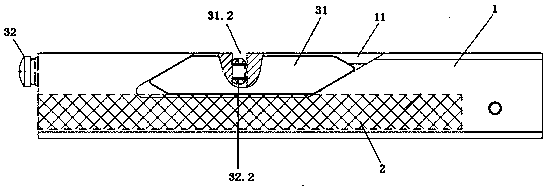

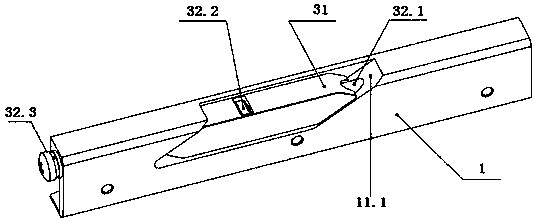

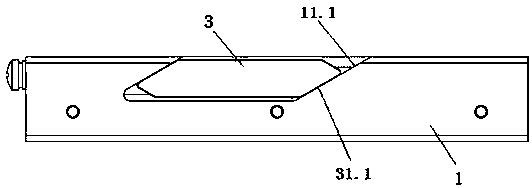

[0034] A vibration-damping installation structure of a functional module in a box, comprising a chute 1 installed in the box and a guide rail 2 installed on the functional module, the guide rail 2 slides and fits with the chute 1 and is inserted into the chute 1, and the The functional module is installed in the sub-box, and it is characterized in that the vibration-damping and compressing device 3 is installed on the chute 1, and the vibration-damping and compressing device 3 moves on the chute 1 to compress the guide rail 2 or loosen the pair The compression of rail 2.

[0035] The vibration damping and pressing device 3 includes a wedge-shaped pressing block 31 and a screw assembly 32, the wedge-shaped pressing block 31 and the screw assembly 32 are arranged along the length direction of the chute 1, and the wedge-shaped pressing block 31 is located directly above the guide rail 1, And not in contact with the guide rail 1, the two sides of the wedge-shaped pressing block 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com