Tobacco bare seed seeding device and method

A seeder and tobacco technology, applied in the directions of seeder parts, manual sowing tools, seed coating/seed dressing, etc., can solve the problems of lack of seedlings, increase the difficulty of separation, waste, etc., to prevent seed waste, improve The effect of high germination efficiency and sowing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with accompanying drawing:

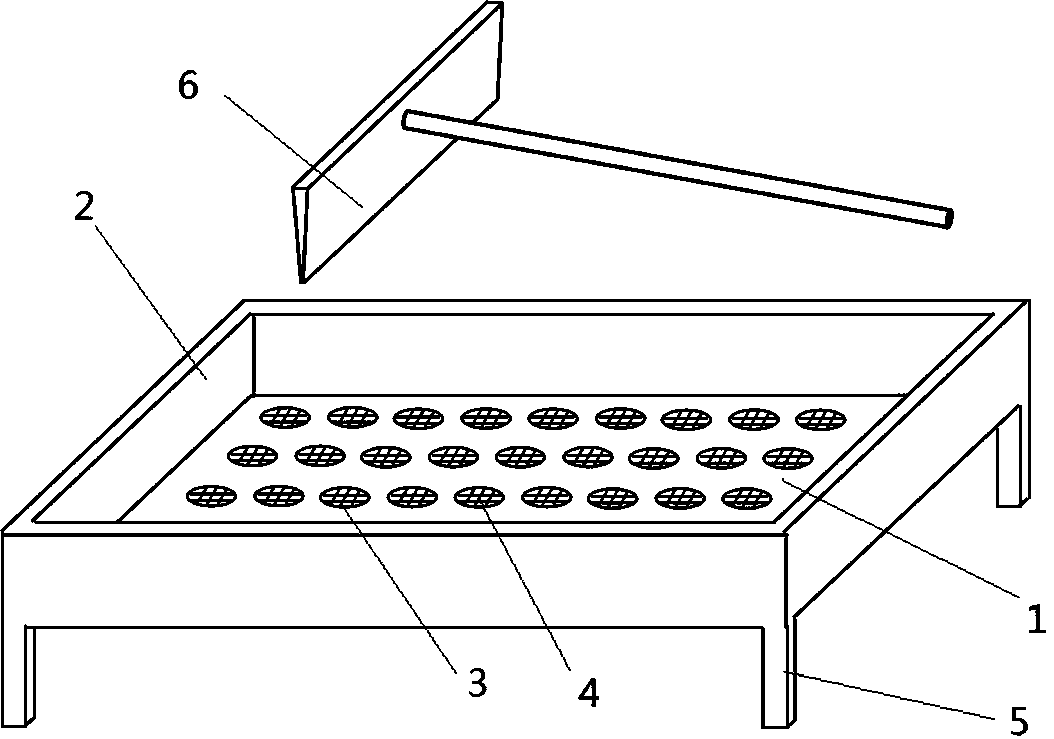

[0023] Such as figure 1 Shown: the bare tobacco seed sower of the present invention comprises a rectangular sowing disc 1 with a baffle plate 2 on all sides, and the disc surface of the sowing disc is provided with a through hole 3 corresponding to the cavity of the tobacco seedling raising disc, wherein: the through hole diameter is 3-5mm, each hole is provided with a 40-mesh screen 4, the edge of the screen is smooth and wrinkle-free, and the four corners of the rectangular seeding tray are provided with fixed clips 5 for clamping the outer corners of the tobacco seedling tray, And the horizontal section of the fixed clamping foot 5 is a right-angle steel structure, and a push plate 6 is also equipped with this seeder.

[0024] The specific usage method and process are as follows:

[0025] 1. Before sowing, sieve the dried seedling substrate with a 40-mesh sieve and mix it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com