Additional material support structure

A technology of support structure and support sheet, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of construction failure, affecting the shape accuracy and dimensional accuracy of the workpiece, and collapse, and achieve effective support and prevent workpiece deformation. , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

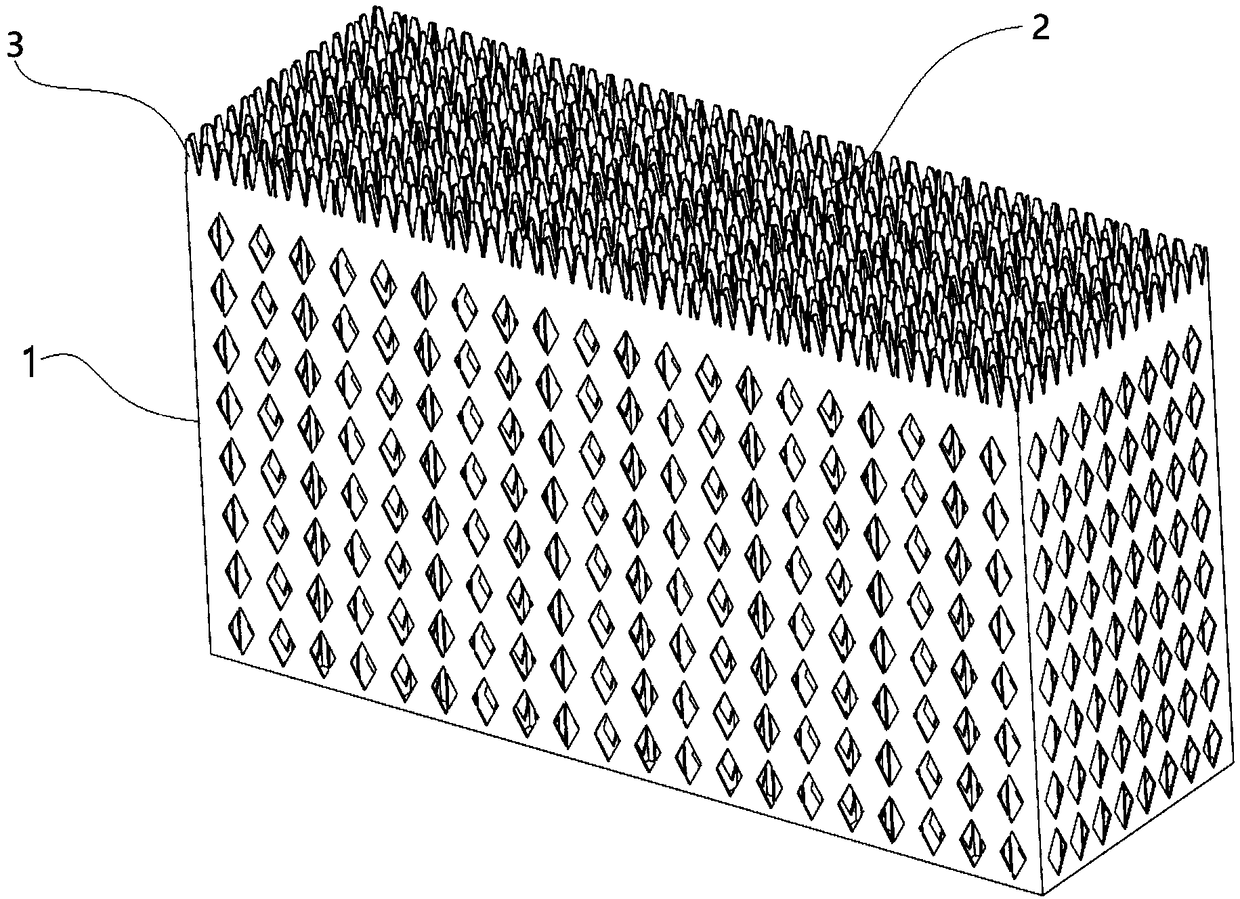

[0038] Please refer to figure 1 -5, this embodiment provides an additive support structure for supporting workpieces in the metal powder 3D printing process, including a support body 1, the support body 1 is a honeycomb structure; the side of the support body 1 for supporting the workpiece is The support surface 2 is provided with a plurality of support sheets 3 .

[0039] The support structure is used to support the metal powder 3D printing workpiece. The bottom surface 5 of the support body 1 is connected to the workbench. The support surface 2 of the support body 1 is used to support the workpiece. The support body 1 is a honeycomb structure; The support piece 3 supports the workpiece, the honeycomb support body 1 and the support piece 3 reduce the loss of support structure materials, the support piece 3 supports the workpiece, and facilitates the cutting and separation between the support body 1 and the workpiece.

[0040] The end of the support piece 3 connected to the s...

Embodiment 2

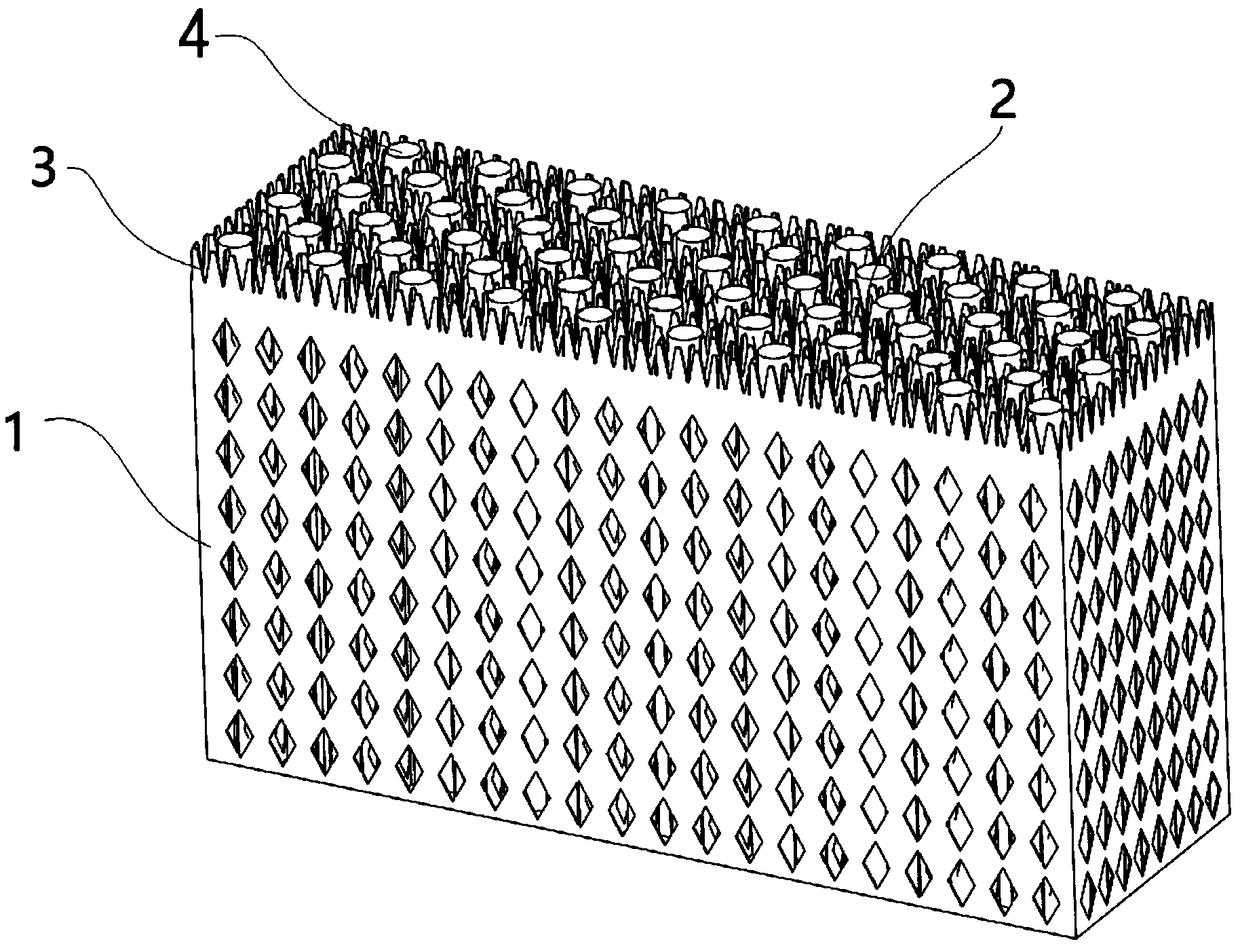

[0049] to combine figure 1 ,refer to Figure 4As shown, this embodiment provides an additive support structure, the support structure is used to support the workpiece in the metal powder 3D printing process, the support structure includes a honeycomb support body 1 or a plurality of lateral and Holes arranged vertically, the support body 1 is fixed on the workbench. The top surface of the support body 1 is the support surface 2, the bottom surface 5 of the support body 1 is fixedly connected with the workbench, and a plurality of support sheets 3 are arranged on the support surface 2, and the support sheets 3 are connected with the workpiece and support the workpiece. The honeycomb support body 1 and The support sheet 3 reduces the loss of supporting structure materials, supports the workpiece, and facilitates cutting and separation between the support body 1 and the workpiece.

[0050] The end of the support piece 3 connected to the support surface 2 is larger than the end ...

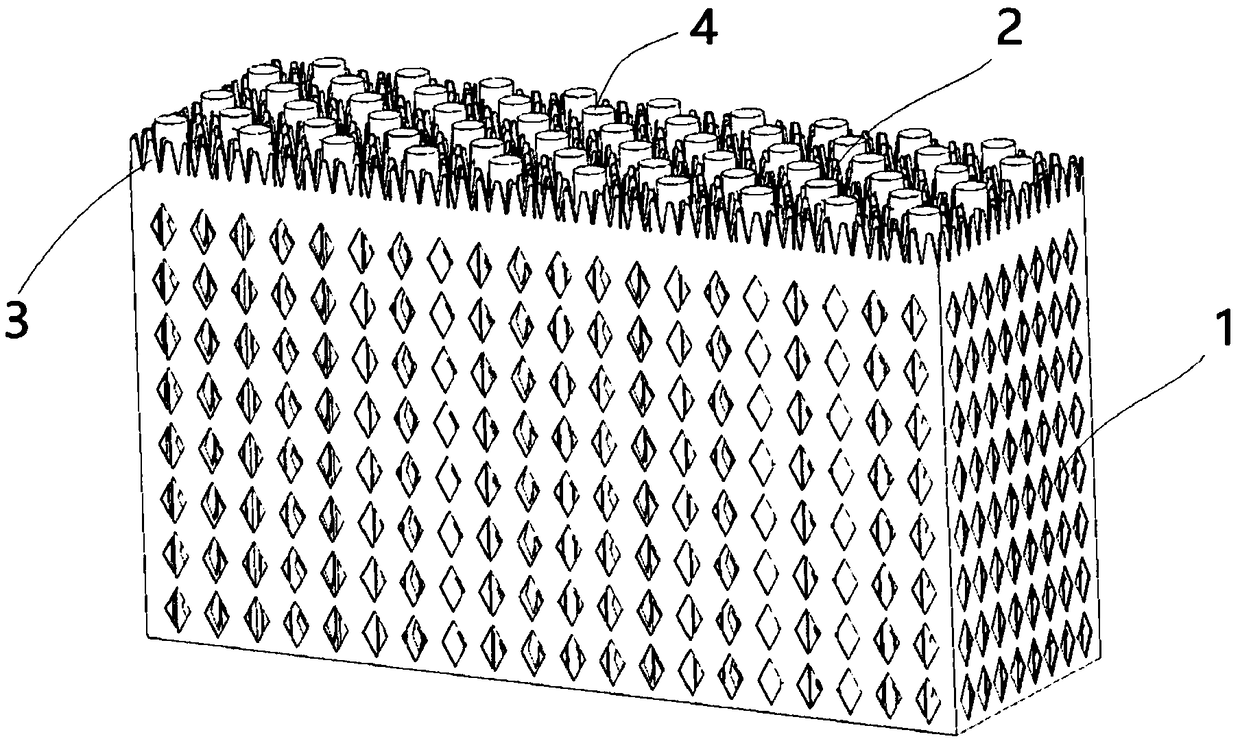

Embodiment 3

[0052] combine figure 2 , image 3 and Figure 4 ,refer to Figure 5 As shown, this embodiment provides an additive support structure, the support structure is used to support the workpiece in the metal powder 3D printing process, the support structure includes a honeycomb support body 1 or a plurality of lateral and Holes arranged vertically, the support body 1 is fixed on the workbench. The top surface of the support body 1 is the support surface 2, the bottom surface 5 of the support body 1 is fixedly connected with the workbench, and a plurality of support sheets 3 are arranged on the support surface 2, and the support sheets 3 are connected with the workpiece and support the workpiece. The honeycomb support body 1 and The support sheet 3 reduces the loss of supporting structure materials, supports the workpiece, and facilitates cutting and separation between the support body 1 and the workpiece.

[0053] The end of the support piece 3 connected to the support surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com