Special fast heat radiator for gear processing

A cooling device and gear technology, which is applied to gear teeth manufacturing devices, metal processing equipment, belts/chains/gears, etc., can solve problems that affect the normal processing of parts, iron filings stick to parts, and reduce structural strength, etc., to achieve production High efficiency, high precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

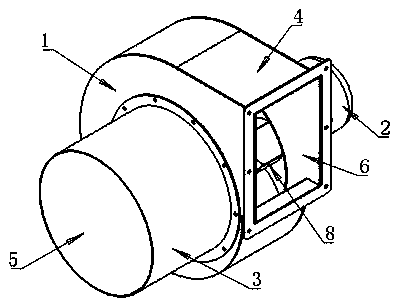

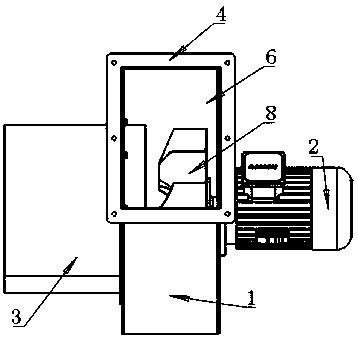

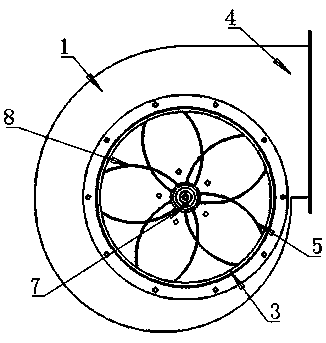

[0018] Such as Figure 1 to Figure 6 As shown, a special rapid cooling device for gear processing can quickly cool the gear structures arranged in different directions at the same time, which can make the gear structure more stable during production and processing, and can also protect the gear structure itself. Strength, so that the precision of the produced parts is higher, and it can be cooled at the same time during the processing process, so that the overall production efficiency of the parts is higher, thereby reducing the overall production cost in the production process, and the stability of the device during use It has better performance and longer service life. During use, it can dissipate heat to parts in different directions according to needs, making it more flexible and convenient to use. It includes a cylindrical heat sink main body 1, and a heat dissipation power motor 2 is connected to the center of the right end surface of the heat sink main body 1, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com