An ultrasonic cutting and welding composite mechanism

A technology of cutting welding and ultrasonic, which is applied in the field of ultrasonic cutting and welding composite mechanism, can solve the problems of wasted space, unsynchronized cooperation, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

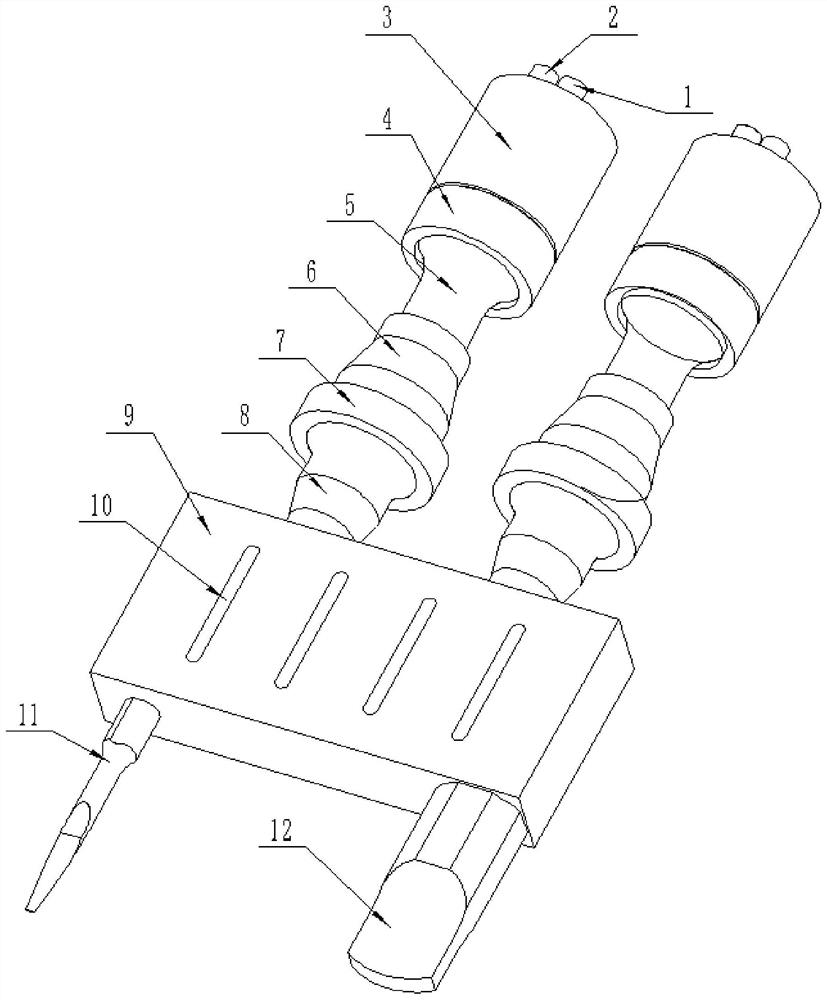

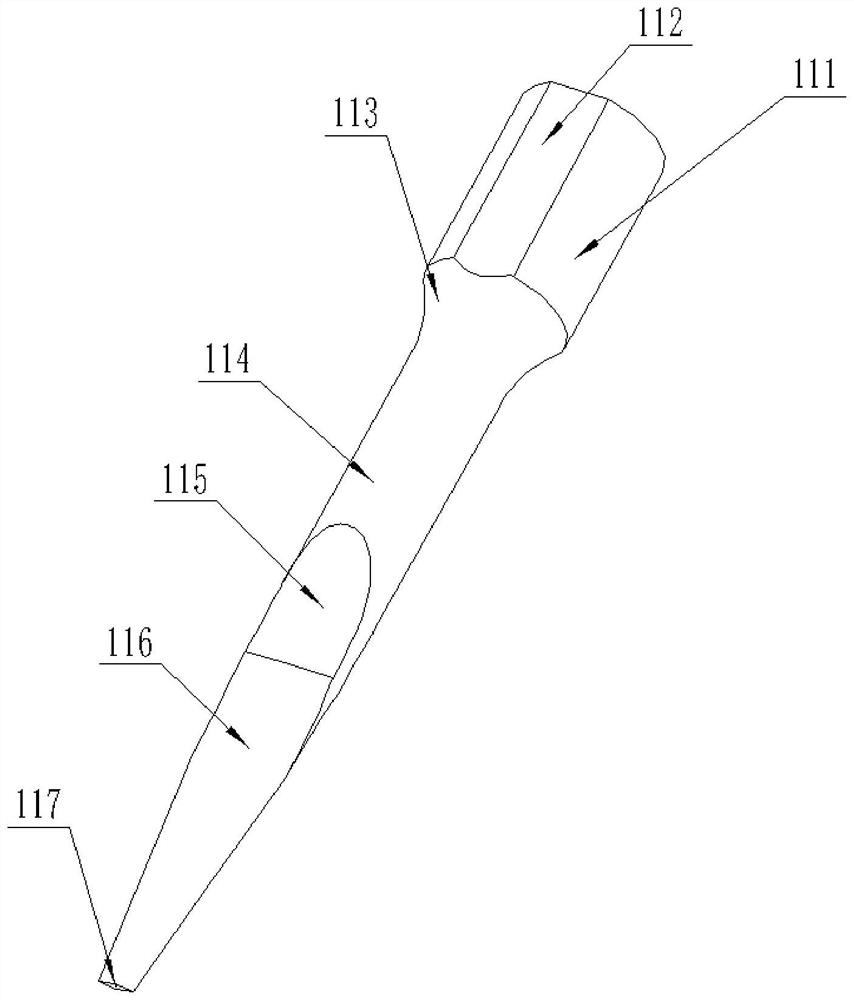

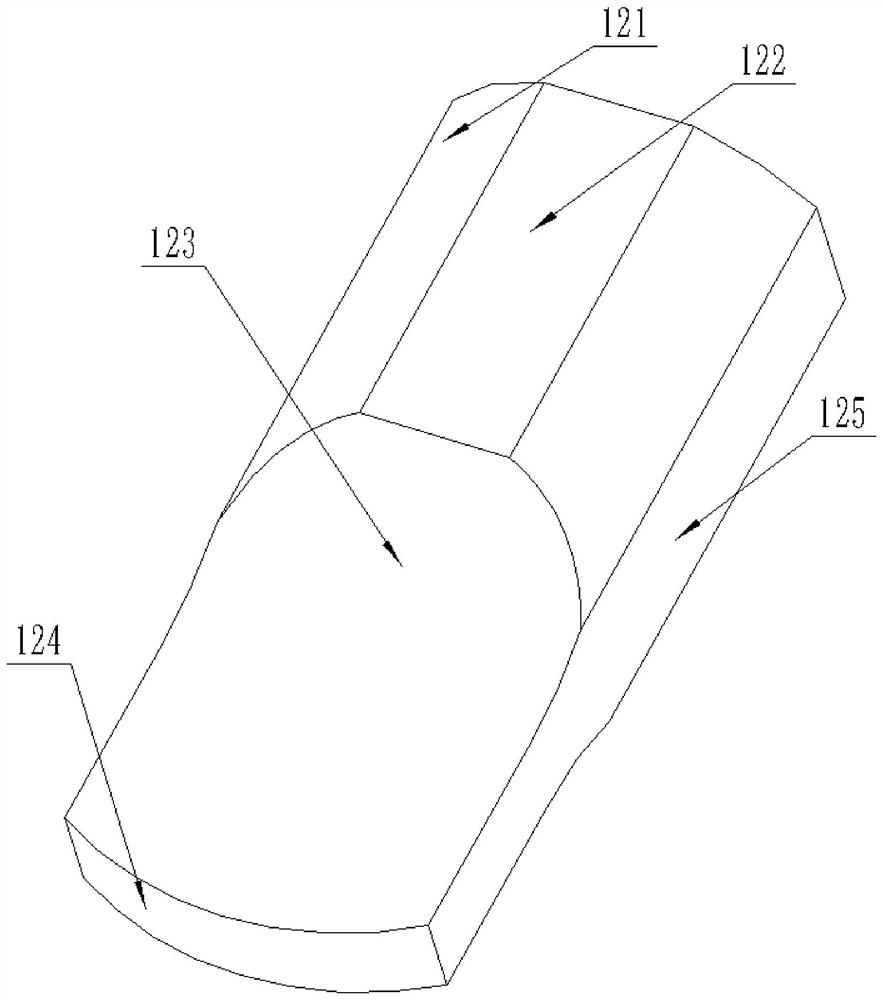

[0015] Such as figure 1 As shown, this specific embodiment adopts the following technical scheme: an ultrasonic cutting and welding composite mechanism, including a high-frequency signal line 1, a compressed air interface 2, a transducer upper shell 3, a transducer lower shell 4, and a transducer precursor End 5, amplitude modulator rear end 6, amplitude modulator collar 7, amplitude modulator front end 8, female tool head 9, groove 10, ultrasonic cutting head 11 and ultrasonic welding head 12; the outer surface of said female tool head 9 is provided with several a groove 10; the two sides of the lower end of the female tool head 9 are respectively connected with an ultrasonic cutting head 11 and an ultrasonic welding head 12; both sides of the upper end of the female tool head 9 are connected with an amplitude modulator front end 8; the front end of the amplitude modulator 8 are connected with an amplitude modulator rear end 6; the outer surface of the connection between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com