Coal mining face non-gap feeding coal cutting complete device and feeding method

A technology for coal mining face and complete sets of equipment, which is applied to earth-moving drilling, cutting machinery and other directions, can solve the problems of increasing mining face cycle time, decreasing regular cycle rate, and difficulty in safety management, and reducing material costs and labor. The effect of cost, reduction of operation time, and reduction of process preparation links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Example:

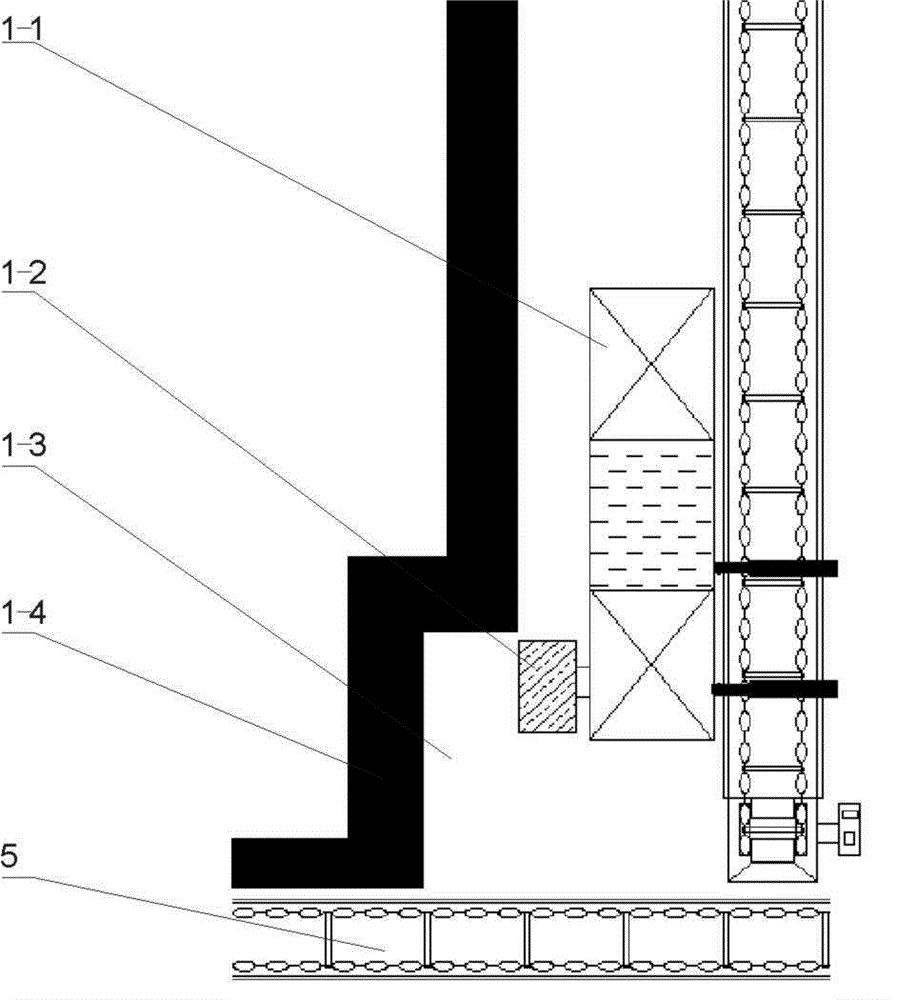

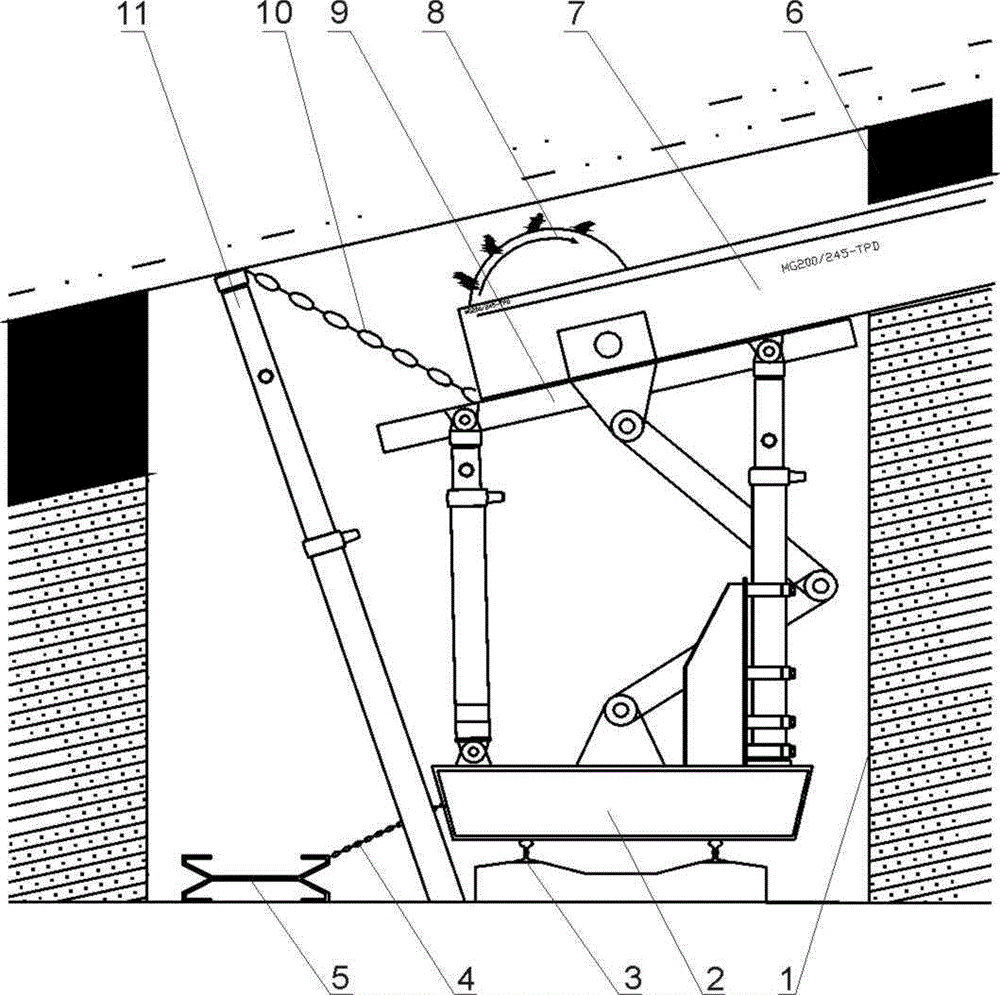

[0060] The complete set of coal mining equipment provided by the present invention with no gaps in the coal mining face includes a coal mining machine 7 arranged on the coal mining face 6, a scraper conveyor 5 arranged in the machine lane, and a mining machine is also arranged in the machine lane. The coal machine support trolley is used to support the nose part of the coal shearer.

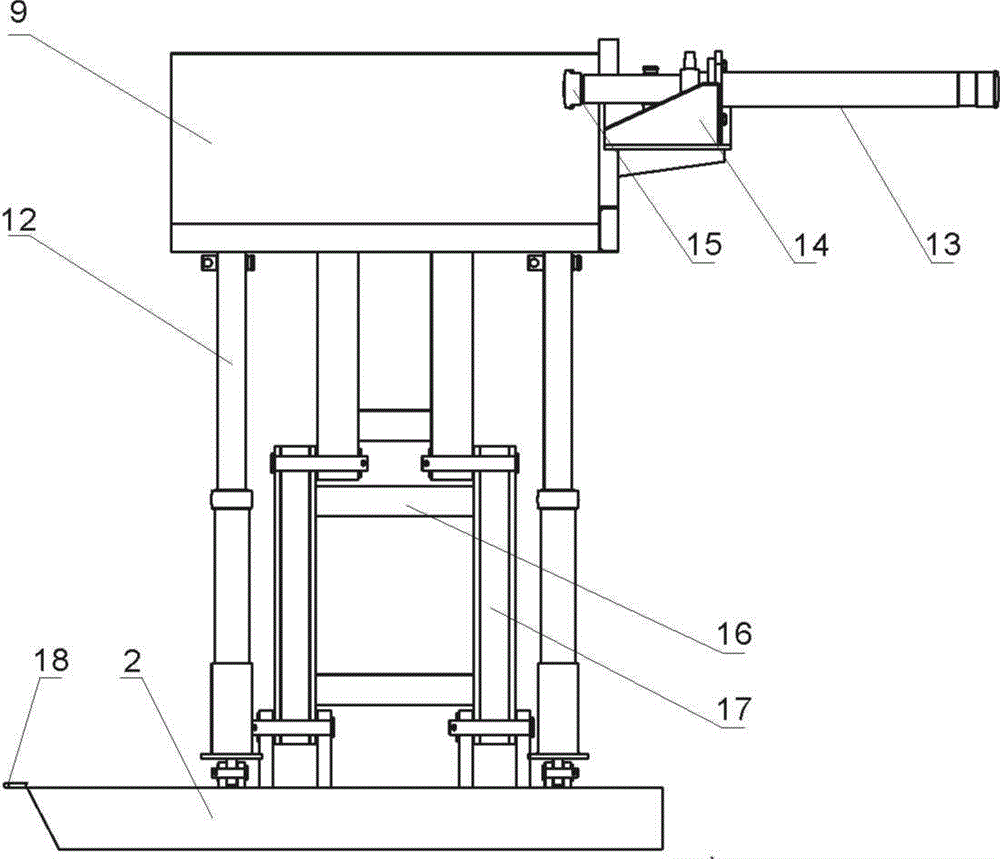

[0061] The support trolley of the coal mining machine includes a support platform 9 at the top and a bearing platform 2 at the bottom. Because there is often a large amount of floating coal and gangue at the bottom of the coal mining roadway, it is inconvenient to move the supporting trolley of the coal mining machine, so in the embodiment, a slide rail 3 can be installed at the bottom of the supporting trolley to make the supporting trolley more Walk easily. The length, width and platform thickness of the supporting platform are designed to be 1600×1300×100mm; the length, wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com