2.5D glass charging and discharging equipment for bevel grinding machine

A technology on oblique grinding machines and glass, which is applied to grinding/polishing equipment, metal processing equipment, and parts of grinding machine tools. It can solve the problems of high production cost, low production efficiency, manpower and time, and reduce The effect of production cost, improvement of production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

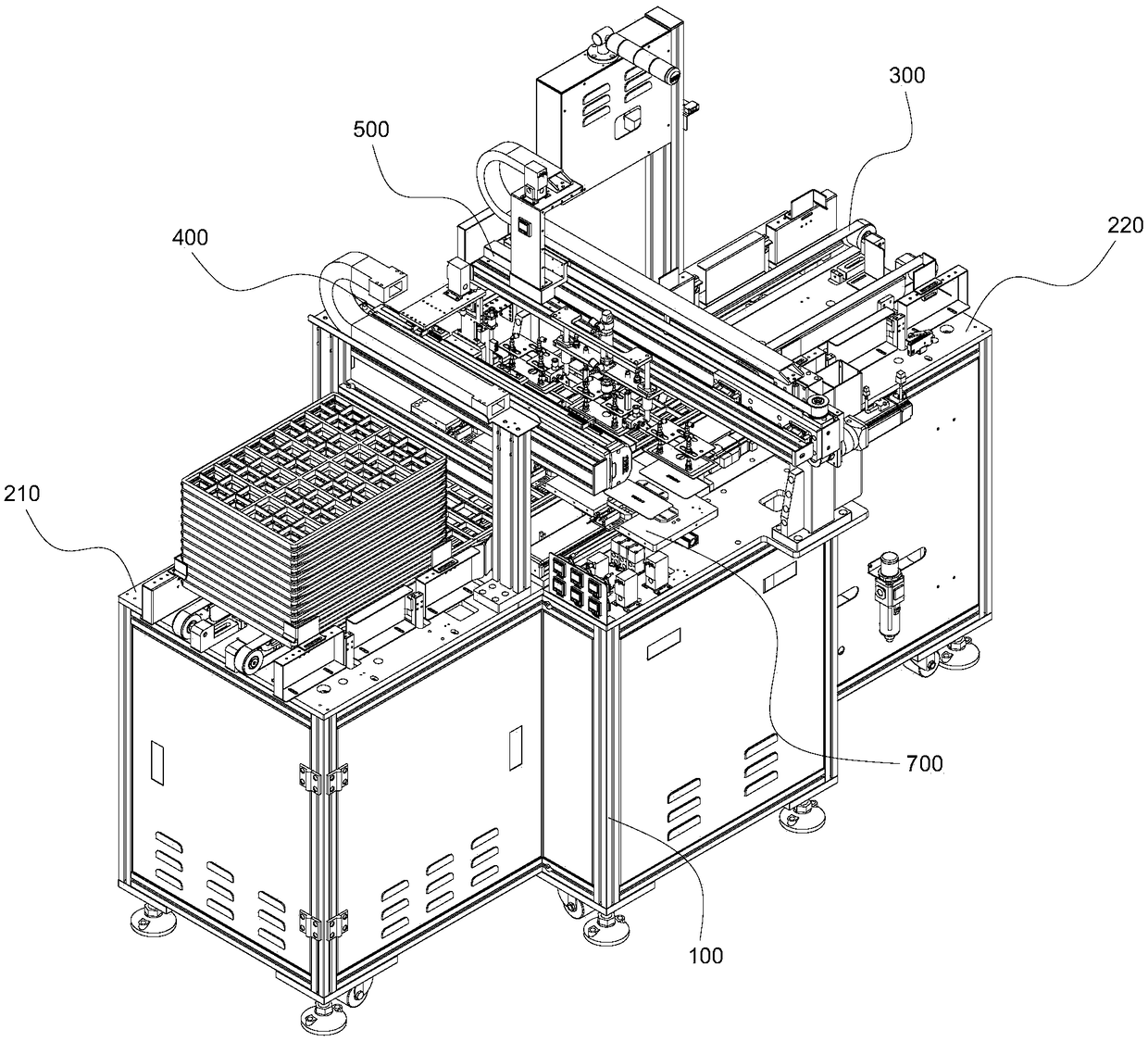

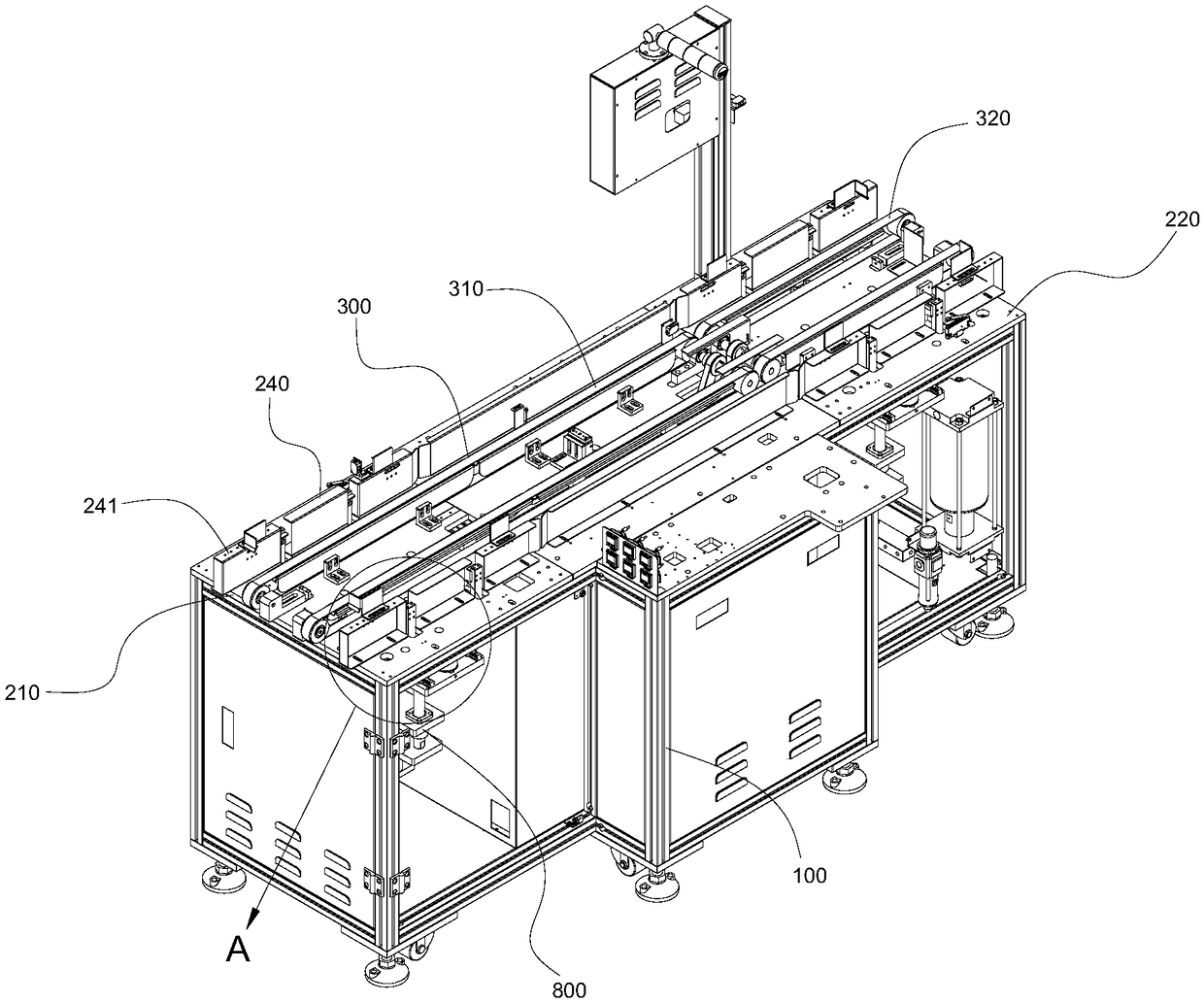

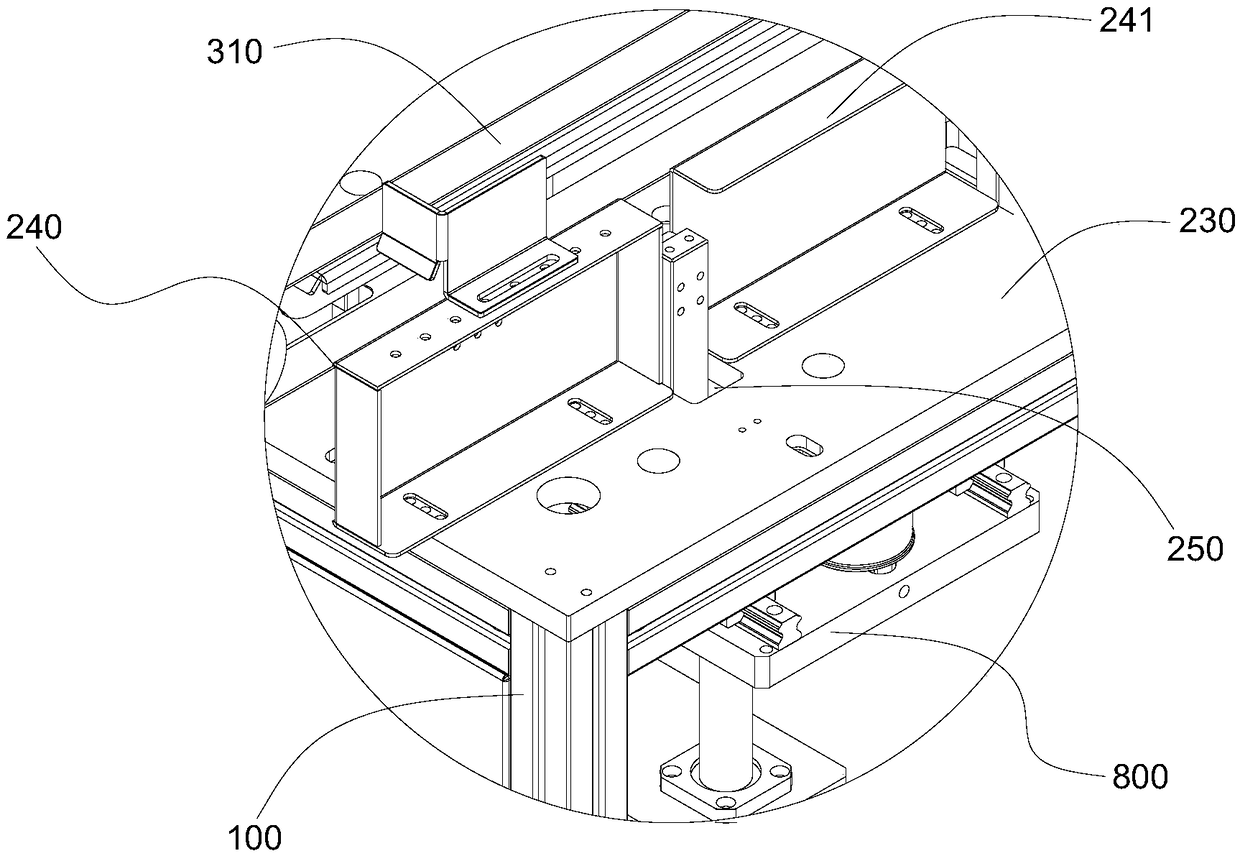

[0030] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention discloses a 2.5D glass loading and unloading device for an inclined grinder, including a frame 100, a stacked tray feeding mechanism 210 installed at both ends of the frame 100, and a stacked tray bottom. A material mechanism 220, a conveyor belt 300 is installed on the top surface of the frame 100, and the two ends of the conveyor belt 300 extend to the top surfaces of the stacked tray feeding mechanism 210 and the stacked tray unloading mechanism 220 respectively; A plurality of stacks for placing workpieces are stacked on the stack loading mechanism 210, and the stacks are transported through the conveyor belt 300 and finally collected and stacked at the stack blanking mechanism 220; the conveyor belt 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com