Deformable wood board combining machine scraping structure adopting overlapped magnetic positioning

A technology of machine scraping and magnetic positioning, which is applied to wood processing equipment, adhesive application devices, manufacturing tools, etc., and can solve problems such as easy scratches on the surface of wood boards, overflowing glue, and taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

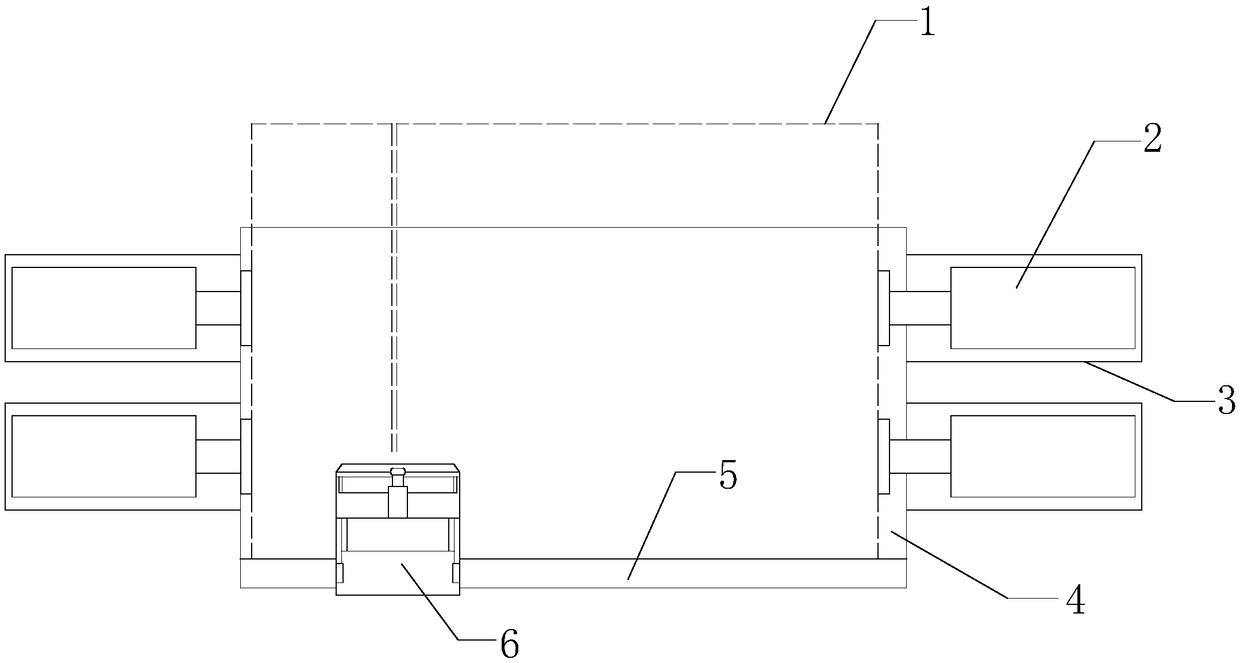

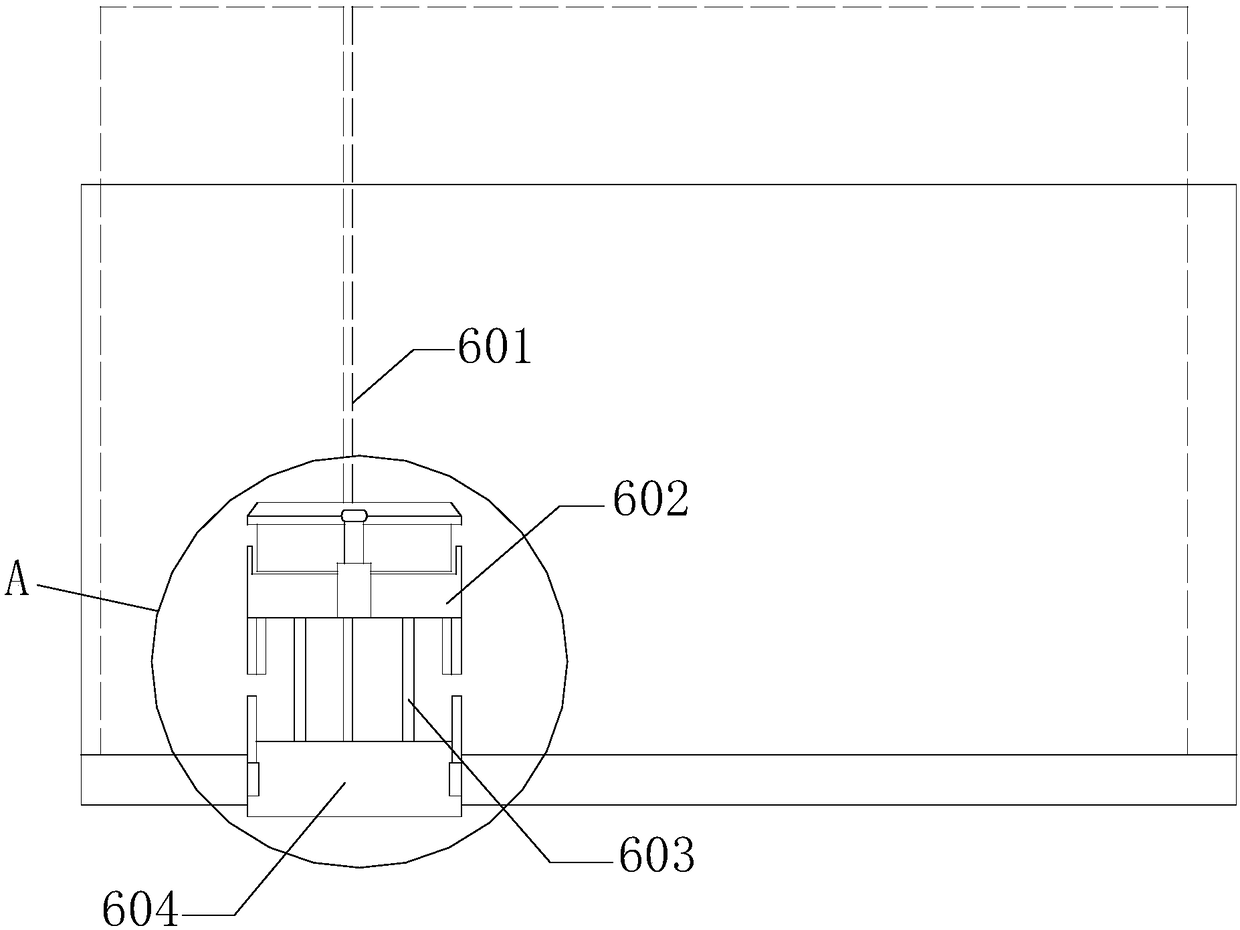

[0029] see Figure 1-Figure 6 , the present invention provides a scraper structure for a deformable plank combination machine that adopts magnetic stacking positioning. one, and respectively installed on the surface of the mounting plate 3, the mounting plate 3 is provided with four, and respectively installed on the left and right sides of the platform 4, the front end of the platform 4 is provided with a main rail 5, and is an integrated structure, the The workpiece 1 is arranged on the surface of the platform 4, and both sides are connected with the cylinder 2, the scraper 6 is fastened with the main rail 5, and the mounting plate 3 is used to fix the cylinder 2 on both sides of the platform 4. The plank is placed on the platform 4, and then the two planks are pushed by the cylinder 2 to be combined and close together.

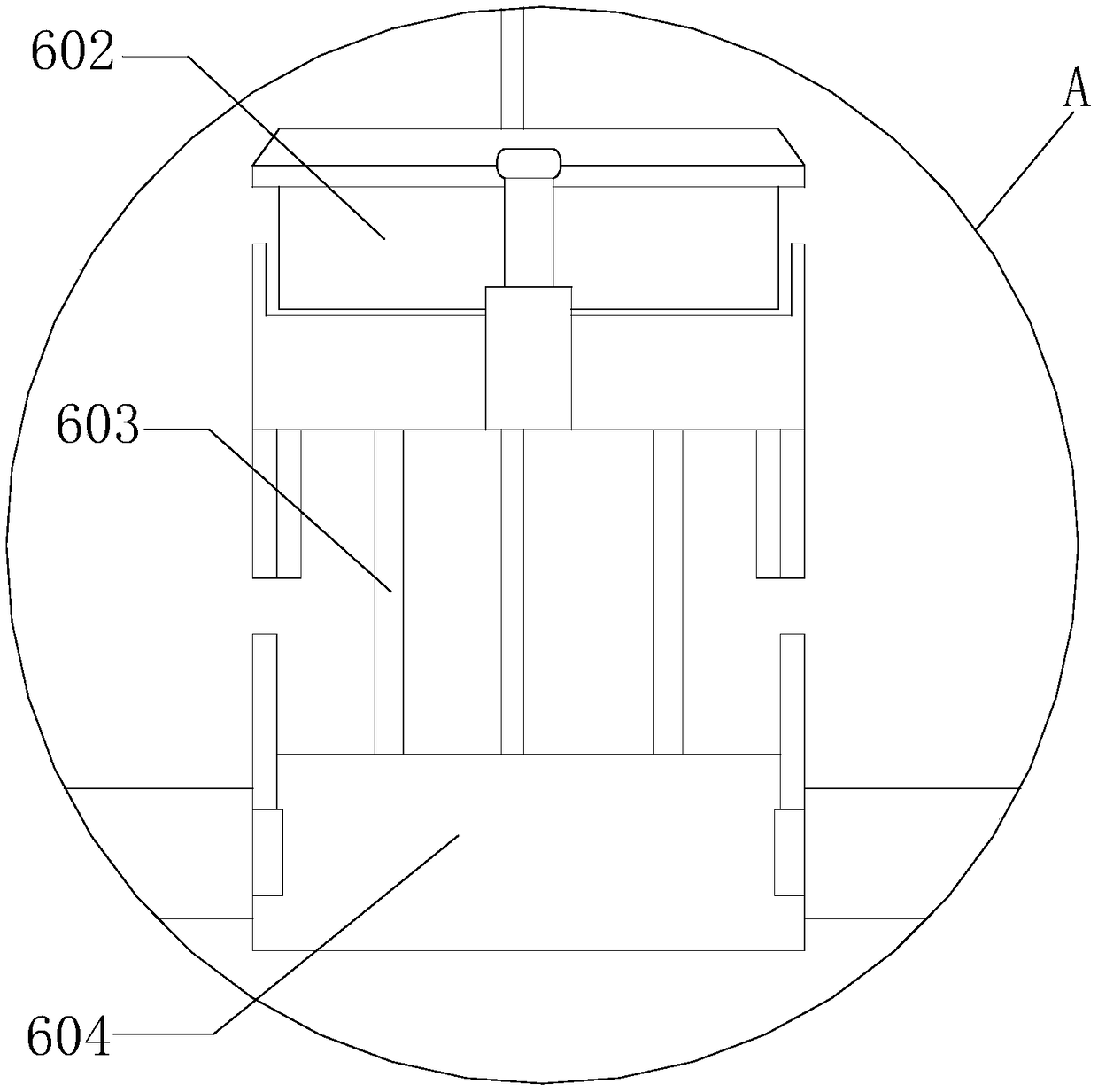

[0030] The scraper 6 includes a combination line 601, a parallel scraper frame 602, a return bar 603, and a translator 604. The translator 604 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com