Waste granite regenerated water permeable brick manufacturing device

A technology for granite waste and manufacturing equipment, which is applied in the direction of unloading equipment, manufacturing tools, ceramic molding workshops, etc., can solve the problems of cumbersome and complicated equipment operation methods, reduce the strength of paved roads, and high manufacturing costs, and achieve convenient and simple equipment operation methods , Increase the firing efficiency and increase the production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

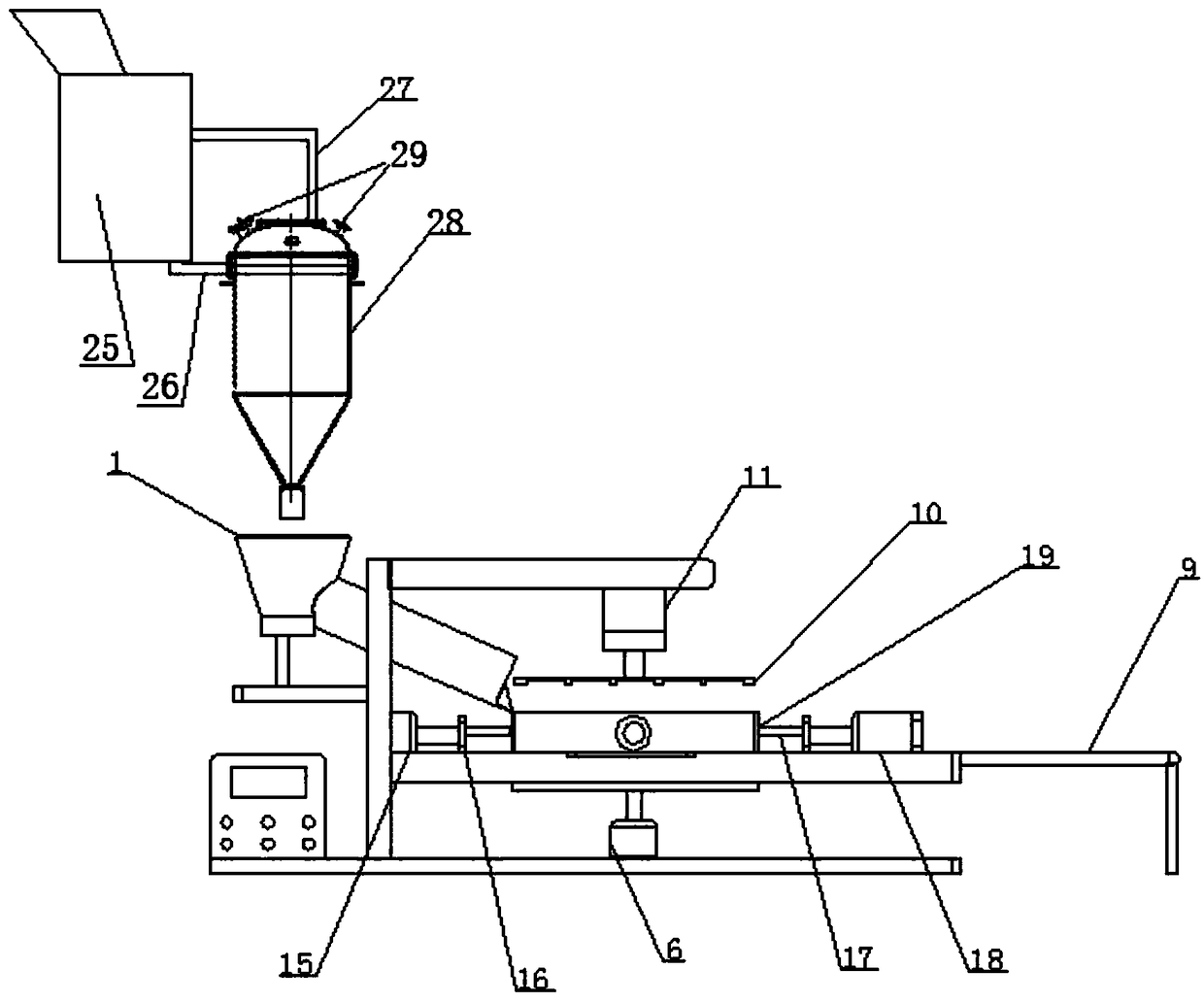

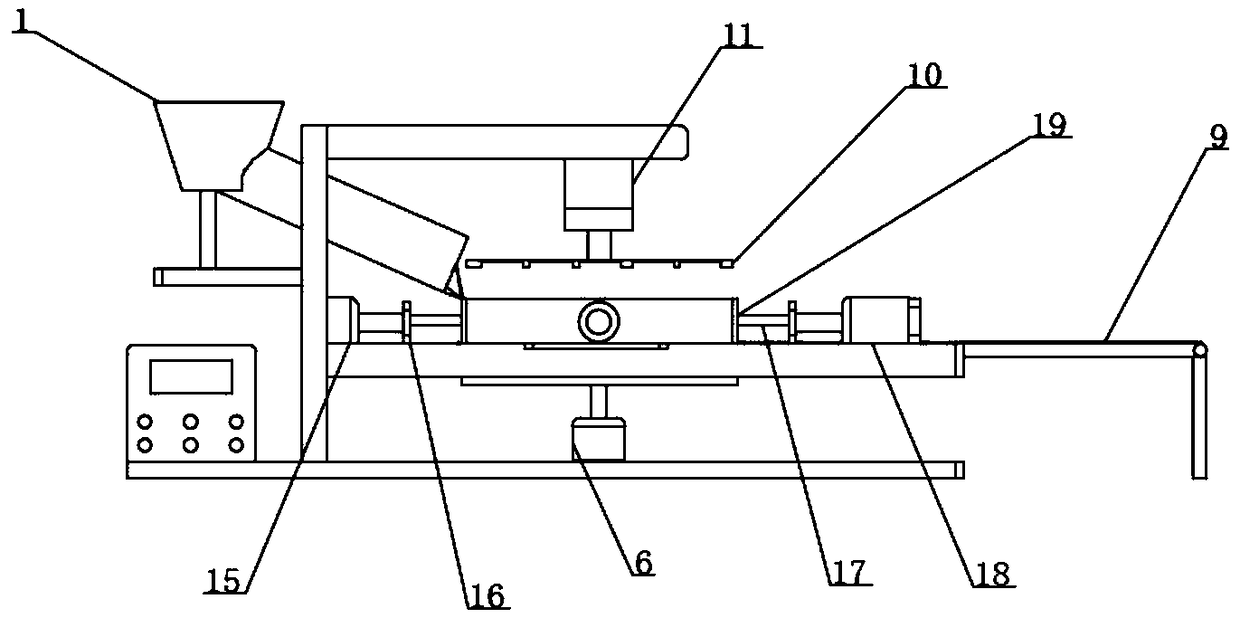

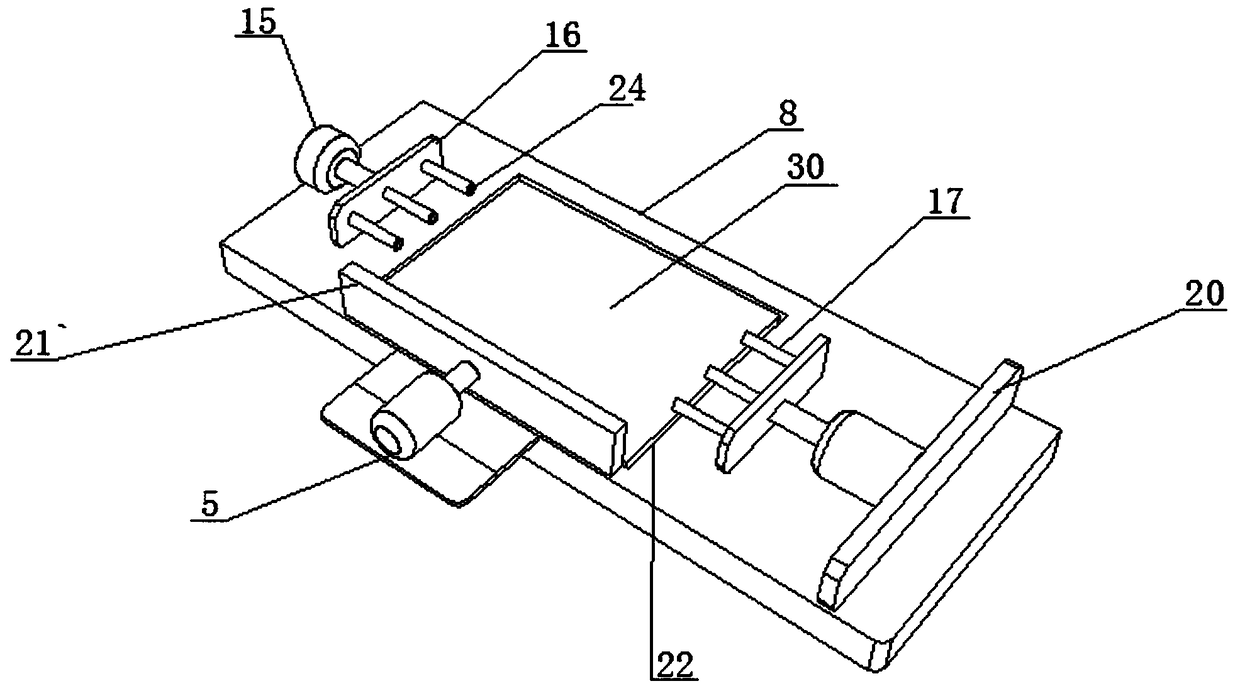

[0032] See Figure 1~5 In an embodiment of the present invention, a manufacturing device for granite waste recycled permeable bricks includes a granite waste crushing mill, a mixer, a forming component, a conveying component and a sintering kiln, and is characterized in that:

[0033] The molding component is fixedly arranged on the base 7, and one end of the base 7 is provided with a feed port 1 connected with the molding component;

[0034] The mixer 28 is provided above the feed inlet 1, and the granite waste crushing and pulverizing device 25 is connected to the mixer. The granite waste crushing and pulverizing device 25 can be connected to the mixer. Supply of granite powder and granite stones;

[0035] The molding component realizes the molding of the water-permeable brick, and the lower end of the molding component is provided with an oscillating component so as to oscillate the aggregate during molding;

[0036] The conveying component is arranged on one side of the base, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com